Aluminum Square Bar 6082

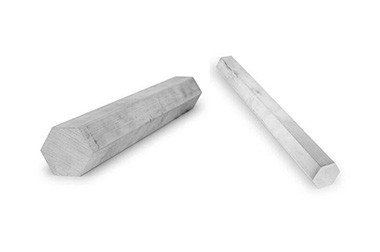

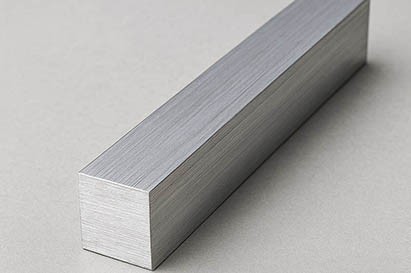

The 6082 aluminum square bar is a square-section profile made from 6082 aluminum alloy. The square bar form of 6082 aluminum is shaped through an extrusion process, and its cross-sectional shape is suitable for scenarios requiring high geometric precision, such as architectural profiles and mechanical frameworks.

With its comprehensive performance, the 6082 aluminum square bar enables lightweight design, high reliability, and good manufacturing adaptability in aerospace applications. For non-load-bearing structural parts, engine auxiliary components, electronic equipment housings, seat assemblies, and cabin interiors, it achieves an ideal balance among cost, performance, and processing efficiency.

The 6082 aluminum square bar is a medium-strength, heat-treatable wrought alloy in the 6xxx series. It is praised for its excellent corrosion resistance, good weldability and machinability, and high strength-to-weight ratio. Its chemical composition—mainly aluminum, with added silicon, magnesium, and manganese—helps refine grain structure and enhance mechanical properties. 6082 square bars are typically extruded in T6 and T651 tempers and are widely used in structural, automotive, and general engineering fields that demand strength and durability.

Owing to its balanced properties, 6082 aluminum is widely used in structural and industrial applications. The addition of manganese gives it higher strength compared to alloys such as 6061, helping to refine its grain structure.

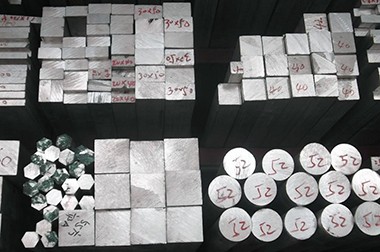

Aluminum Square Bar 6082 Specifications

| Item | Description |

| Alloy Grade | 6082 |

| Temper | T4 (Natural Aging) |

| T6 (Solution Heat Treated and Artificially Aged) | |

| T6511 (Stress Relieved) | |

| Dimension | Square Bar Side Length: 6.35 mm (¼") to 220 mm (8.66") |

| Length: 1–6 meters (standard), customizable | |

| Standards | ASTM B221 (Extruded Bars) |

| EN 573-3 | |

| EN 755-2 | |

| AMS 4156 | |

| Classification Society Certification | CCS (China Classification Society) |

| DNV (Det Norske Veritas) | |

| LR (Lloyd’s Register) | |

| BV (Bureau Veritas) |

Aluminum Square Bar 6082 Chemical Composition

The typical composition of 6082 aluminium alloy is:

- Aluminium (Al): 95.2–98.3 wt %

- Silicon (Si): 0.7–1.3 wt %

- Magnesium (Mg): 0.6–1.2 wt %

- Manganese (Mn): 0.4–1.0 wt %

- Iron (Fe): ≤ 0.5 wt %

- Copper (Cu): ≤ 0.1 wt %

- Chromium (Cr): ≤ 0.25 wt %

- Titanium (Ti): ≤ 0.1 wt %

- Zinc (Zn): ≤ 0.2 wt %

- Residuals: ≤ 0.15 wt %

The addition of manganese refines grain size, boosting strength, while silicon and magnesium form hardening precipitates during heat treatment .

Aluminum Square Bar 6082 Mechanical Properties

In the T6 temper, extruded 6082 square bars exhibit:

- Ultimate Tensile Strength: 280–310 MPa (depending on section size)

- Yield Strength (0.2%): 240–270 MPa

- Elongation at Break: 5–8 %

- Brinell Hardness: ≈ 82 HB (range 60–95 HB depending on temper)

Compared to 6061, 6082 offers roughly 10–20 % higher strength, making it the highest-strength alloy in the 6000 series .

Aluminum Square Bar 6082 Physical and Thermal Properties

- Density: ≈ 2.71 g/cm³

- Young’s Modulus: ≈ 70 GPa

- Shear Modulus: 26.4 GPa

- Thermal Conductivity: 170–220 W/m·K

- Coefficient of Thermal Expansion: 23.1–23.4 × 10⁻⁶ K⁻¹ (20–100 °C)

- Specific Heat: 896 J/kg·K

These properties make 6082 square bars suitable for components subjected to temperature fluctuations and moderate thermal loads.

Aluminum Square Bar 6082 Manufacturing, Tempers, and Surface Treatments

6082 is typically supplied in extruded square bar form, with the following tempers:

- T6 (Solution heat-treated and artificially aged): Provides peak strength and good machinability.

- T651 (T6 with stress-relieving by stretching): Enhances dimensional stability of precision components.

- Machinability: In T6/T651 temper, 6082 machines cleanly and produces tight chip curls when chip breakers are used.

- Weldability: Good weldability using MIG, TIG, and resistance welding; however, if strength restoration is critical, post-weld heat treatment is recommended due to potential reduction in welded joint strength.

- Anodizing: Easily anodized to improve surface hardness and corrosion resistance; commonly used in architectural and decorative applications.

Applications of Aluminum Square Bar 6082 in the Aerospace Industry

Aircraft Structures (Non-Load-Bearing)

6082 square bars are commonly used in fuselage interior support frames, partition frames, and door hinge mounts.

- Reason: These structures do not bear primary aerodynamic loads but must maintain dimensional stability and rigidity to ensure cabin sealing, sound insulation, and assembly precision.

- Advantage: Better crack resistance and corrosion resistance than 2xxx series alloys, reducing the need for frequent coating maintenance; excellent machinability allows for complex geometries with CNC machining.

Engine Components

Includes intake duct support plates, deflectors, brackets, and other non-high-temperature core parts.

- Reason: Engine compartments typically operate within 100–200 °C, and 6082 has sufficient thermal stability to maintain mechanical properties in this range.

- Advantage: High strength ensures resistance to deformation under airflow vibrations and centrifugal forces; excellent corrosion resistance withstands lubricants, fuels, and humid environments.

Aerospace Electronic Device Enclosures

Such as housings for Inertial Measurement Units (IMUs), power modules, and antenna brackets.

- Reason: Electronic devices require high electromagnetic shielding, thermal conductivity, and tight dimensional tolerances; enclosures must be lightweight and durable.

- Advantage: Good thermal conductivity facilitates heat dissipation from electronic components; anodizing creates an insulating oxide layer that improves electrical insulation and wear resistance; CNC machining enables precision milling with ±0.05 mm tolerance.

Aircraft Seat Components

Including seat frames, rails, locking mechanisms, and armrest supports.

- Reason: Seats must remain structurally sound under loads from takeoff, turbulence, and passenger weight; compliance with fire-retardant and corrosion resistance regulations is also required.

- Advantage: High strength-to-weight ratio meets fatigue life requirements while reducing weight; excellent machinability allows complex curved frames and rails to be formed in a single step; anodizing enhances surface hardness and facilitates adherence of fire-retardant coatings.

Interior Design and Decoration (Cabin Interiors)

Including overhead luggage bin supports, decorative panel backings, and air outlet frames.

- Reason: Cabin interiors must be lightweight, compatible with decorative elements (plastics, fabrics), and meet requirements for fire resistance, corrosion resistance, and scratch resistance.

- Advantage: 6082 square bars can be extruded or CNC machined, then anodized to achieve various colors and textures; increased hardness resists minor scratches; aluminum’s recyclability aligns with environmental and sustainability goals.

Applications of Aluminum Square Bar 6082

| Category | Application |

| Structural Components | Frames, supports, brackets in mechanical and construction structures; load-bearing bridge structures; crane arms; roof frameworks |

| Transportation | Automotive chassis parts; vehicle frames; suspension systems; transmission housings; roll cages; trailer components; railway structures; aircraft landing gear components |

| General Engineering / Machinery Manufacturing | Shafts, main shafts, bolts, fittings in industrial equipment; high-precision parts (e.g., valves, pistons); various tools; electronic equipment fittings |

| Architecture and Decoration | Window frames; railings; decorative strips (anodized to enhance weather resistance); platforms; guardrails |

| Marine and Offshore Engineering | Non-critical marine hardware fittings; connectors; decks; masts; railings; offshore structures compliant with ABS, DNV, LR class society standards |

Aluminum Square Bar 6082 Process Performance

- Workability: Excellent formability, weldability (supports TIG/MIG welding), and machinability

- Corrosion Resistance: Suitable for humid or corrosive environments after anodizing or coating treatment

Aluminum Square Bar 6082 Key Production Processes

Melting: Temperature controlled at 740-760℃, with uniform stirring to ensure even composition distribution

Casting: Use of nitrogen and refining agent to purify the melt; during casting, temperature, speed, and cooling water volume must be controlled to minimize defects

Heat Treatment:

- T6 Process: Artificial aging after quenching, significantly improving strength and hardness

- T4 Process: Natural aging, suitable for scenarios requiring subsequent forming operations

Aluminum Square Bar 6082 Advantages and Limitations

Aluminum Square Bar 6082 Advantages

Combination of medium strength and lightweight, high welding efficiency, excellent surface finish after anodizing

Aluminum Square Bar 6082 Limitations

Quenching process requires strict control to avoid cracking due to excessive cooling rate

Aluminum Square Bar 6082 Manufacturing and Processing

- Extrusion: The primary method for producing square bars, providing precise cross-sectional profiles

- Cold Drawing: Improves surface finish and dimensional accuracy

- Machinability: Good in T6 condition, but requires more force than softer alloys like 6063

- Welding: Suitable for TIG/MIG welding, but strength is reduced in the heat-affected zone

Aluminum Square Bar 6082 Key Considerations

- Corrosion Resistance: Excellent for marine and chemical environments due to chromium and manganese content

- Heat Treatment: Enhances alloy strength but requires precise control to avoid warping

- Cost Efficiency: Bulk purchase discounts and repeated use of extrusion dies can reduce costs