Aluminum Rectangular Bar 6063-T52

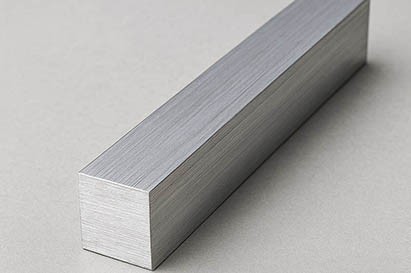

The 6063-T52 rectangular aluminum bar is made from 6063 aluminum alloy through a specific heat treatment process, forming a rectangular cross-sectional aluminum bar.

The T52 temper of 6063 aluminum alloy is a heat-treatable wrought alloy optimized for extrusion. Compared to T5, it offers excellent surface finish, good corrosion resistance, and enhanced dimensional stability. The 6063-T52 rectangular bar meets ASTM B221 and AMS QQ-A-200/8 specifications and is widely used in architectural, marine, electrical, and decorative applications where a smooth surface and anodizing response are critical.

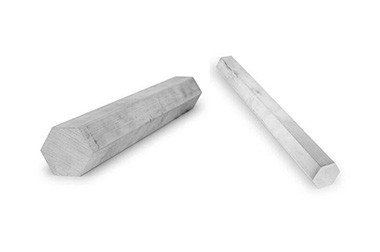

6063 T52 rectangular aluminum bars are known for their medium strength, excellent corrosion resistance, and smooth surface finish. "6063" denotes the alloy composition (primarily aluminum with added magnesium and silicon), while "T52" indicates the tempering process, which includes stress relief and artificial aging to enhance stability and mechanical properties.

Haomei Aluminum’s 6063-T52 aluminum rectangular tube is specifically designed for structural durability and lightweight performance. This extruded aluminum tube features a nominal wall thickness of 1/8 inch (0.125 inch), making it ideal for applications such as construction, automotive frames, and food service equipment. Standard lengths reach up to 72 inches (tolerance options available), and it offers both corrosion resistance and a high strength-to-weight ratio, meeting ASTM standards. We provide custom cutting services and bulk pricing, suitable for industrial projects.

Aluminum Rectangular Bar 6063-T52 Chemical Composition

The 6063 alloy is defined by The Aluminum Association (UNS A96063). "6063" consists primarily of aluminum with magnesium and silicon as the main alloying elements. The typical weight-percent ranges are:

| Element | Min (%) | Max (%) |

| Al | 97.50 | 99.35 |

| Mg | 0.45 | 0.90 |

| Si | 0.20 | 0.60 |

| Fe | — | 0.35 |

| Cr, Cu, Mn, Ti, Zn (each) | — | 0.10 |

| Residuals | — | 0.15 |

Aluminum Rectangular Bar 6063-T52 Physical Properties

- Density: 2.69 g/cm³

- Elastic Modulus: ~69 GPa

- Thermal Conductivity: 201–218 W/m·K

- Coefficient of Thermal Expansion: 23.4 µm/m·K

- Electrical Resistivity: 30–35 nΩ·m

Temper Designation: "T52"

Definition: T52 indicates the alloy has undergone a high-temperature forming process (extrusion) followed by artificial aging treatment to achieve higher strength and hardness while maintaining tighter dimensional tolerances than T5.

Comparison with T5: T5 temper involves lower cooling and aging temperatures, whereas T52 uses a higher-temperature artificial aging cycle, resulting in slightly higher yield strength and excellent dimensional stability under thermal or load cycling.

Aluminum Rectangular Bar Mechanical Properties (T52 Temper)

For rectangular bars with thickness not exceeding 0.5 inch, typical minimum guaranteed properties are as follows:

- Ultimate Tensile Strength: ≥ 20, 000 psi (138 MPa)

- Yield Strength (0.2% offset): ≥ 14, 000 psi (96 MPa)

- Elongation at Break: ≥ 8%

- Hardness (Brinell): ~60 HB

Aluminum Rectangular Bar 6063-T52 Fabrication and Dimensional Tolerances

Manufacturing: Produced via direct extrusion in accordance with ASTM B221 and AMS QQ-A-200/8 standards; bars feature sharp 90° corners and a smooth mill finish surface.

Solid aluminum product.

Surface Finish: Matte mill finish surface, ideal for anodizing and capable of producing a uniform, bright, decorative transparent or colored coating.

Dimensional Tolerances:

Thickness and width tolerances comply with ASTM B221 standards (e.g., for widths < 2 inches, tolerance is ±0.010 inch).

Straightness and flatness are maintained within the commercial positive-side tolerances for T52 temper.

Aluminum Rectangular Bar 6063-T52 Corrosion Resistance and Surface Treatment

- Corrosion Resistance: Excellent general corrosion resistance and good resistance to stress corrosion cracking; suitable for outdoor and marine environments.

- Anodizing Response: Excellent; capable of forming a uniform oxide layer, suitable for decorative and protective applications.

Weldability and Machinability

Weldability: Easily weldable using TIG, MIG, and brazing; post-weld properties near the weld will revert to T0 temper unless re-aged.

Machinability: Approximately 30% better than free-machining alloys; good surface finish achievable with standard tooling.

Aluminum Rectangular Bar 6063-T52 Availability

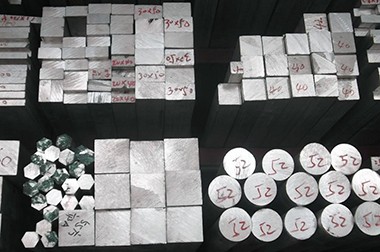

6063 T52 rectangular bars are available in a variety of thicknesses from stock, with custom cutting available.

Standard Dimensions:

- Thickness: 1/8 inch (0.125 inch) to 1 inch.

- Width: 0.5 inch to 6 inches.

- Length: Up to 25 feet (7.62 meters).

Weight: Varies by size; for example, a 0.125 inch x 1 inch bar weighs approximately 0.21 lbs per foot.

6063 Aluminum Rectangular Bar Stock Sizes

| Description | Thickness (in) | Width (in) | Temper | Processing/Surface treatment |

| 1" x 2" Aluminum Rectangular Bar 6063-T52-Extruded | 1" | 2" | 6063-T52 | Extruded |

| 1" x 3" Aluminum Rectangular Bar 6063-T52-Extruded | 1" | 3" | 6063-T52 | Extruded |

| 1/16" x 1" Aluminum Rectangular Bar 6063-T52 Extruded | 1/16" | 1" | 6063-T52 | Extruded |

| 1/16" x 1" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/16" | 1" | 6063-T5 | Anodized |

| 1/2" x 1" Aluminum Rectangular Bar 6063-T52-Extruded | 1/2" | 1" | 6063-T52 | Extruded |

| 1/2" x 1 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/2" | 1 1/2" | 6063-T52 | Extruded |

| 1/2" x 2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/2" | 2" | 6063-T52 | Extruded |

| 1/2" x 3" Aluminum Rectangular Bar 6063-T52-Extruded | 1/2" | 3" | 6063-T52 | Extruded |

| 1/2" x 4" Aluminum Rectangular Bar 6063-T52-Extruded | 1/2" | 4" | 6063-T52 | Extruded |

| 1/4" x 3/4" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 3/4" | 6063-T52 | Extruded |

| 1/4" x 1" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 1" | 6063-T52 | Extruded |

| 1/4" x 1 1/4" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 1 1/4" | 6063-T52 | Extruded |

| 1/4" x 5/8" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 5/8" | 6063-T52 | Extruded |

| 1/4" x 1 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 1 1/2" | 6063-T52 | Extruded |

| 1/4" x 2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 2" | 6063-T52 | Extruded |

| 1/4" x 2 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 2 1/2" | 6063-T52 | Extruded |

| 1/4" x 4" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 4" | 6063-T52 | Extruded |

| 1/4" x 1" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/4" | 1" | 6063-T5 | Anodized |

| 1/4" x 6" Aluminum Rectangular Bar 6063-T52-Extruded | 1/4" | 6" | 6063-T52 | Extruded |

| 1/8" x 1/2" Aluminum Rectangular Bar 6063-T52 Extruded | 1/8" | 1/2" | 6063-T52 | Extruded |

| 1/8" x 3/4" Aluminum Rectangular Bar 6063-T52 Extruded | 1/8" | 3/4" | 6063-T52 | Extruded |

| 1/8" x 1" Aluminum Rectangular Bar 6063-T52-Extruded | 1/8" | 1" | 6063-T52 | Extruded |

| 1/8" x 1 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/8" | 1 1/2" | 6063-T52 | Extruded |

| 1/8" x 2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/8" | 2" | 6063-T52 | Extruded |

| 1/8" x 2 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 1/8" | 2 1/2" | 6063-T52 | Extruded |

| 1/8" x 4" Aluminum Rectangular Bar 6063-T52-Extruded | 1/8" | 4" | 6063-T52 | Extruded |

| 1/8" x 3" Aluminum Rectangular Bar 6063-T52-Extruded | 1/8" | 3" | 6063-T52 | Extruded |

| 1/8" x 1/2" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/8" | 1/2" | 6063-T5 | Anodized |

| 1/8" x 1" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/8" | 1" | 6063-T5 | Anodized |

| 1/8" x 1 1/2" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/8" | 1 1/2" | 6063-T5 | Anodized |

| 1/8" x 3/4" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/8" | 3/4" | 6063-T5 | Anodized |

| 1/8" x 2" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/8" | 2" | 6063-T5 | Anodized |

| 1/8" x 2" Anodized Aluminum Rectangular Bar 6063-T5 Black | 1/8" | 2" | 6063-T5 | Anodized |

| 1/8" x 3/4" Anodized Aluminum Rectangular Bar 6063-T5 Bronze | 1/8" | 3/4" | 6063-T5 | Anodized |

| 1/8" x 3/4" Anodized Aluminum Rectangular Bar 6063-T5 Black | 1/8" | 3/4" | 6063-T5 | Anodized |

| 1/8" x 5/8" Aluminum Rectangular Bar 6063-T52 Extruded | 1/8" | 5/8" | 6063-T52 | Extruded |

| 1/8" x 1 3/4" Anodized Aluminum Rectangular Bar 6063-T5 Clear | 1/8" | 1 3/4" | 6063-T5 | Anodized |

| 1/8" x 1" Anodized Aluminum Rectangular Bar 6063-T5 Black | 1/8" | 1" | 6063-T5 | Anodized |

| 1/8" x 1/2" Anodized Aluminum Rectangular Bar 6063-T5 Black | 1/8" | 1/2" | 6063-T5 | Anodized |

| 3/16" x 3/4" Aluminum Rectangular Bar 6063-T52-Extruded | 3/16" | 3/4" | 6063-T52 | Extruded |

| 3/16" x 1" Aluminum Rectangular Bar 6063-T52-Extruded | 3/16" | 1" | 6063-T52 | Extruded |

| 3/16" x 1 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 3/16" | 1 1/2" | 6063-T52 | Extruded |

| 3/16" x 2" Aluminum Rectangular Bar 6063-T52-Extruded | 3/16" | 2" | 6063-T52 | Extruded |

| 3/16" x 1 1/4" Aluminum Rectangular Bar 6063-T52-Extruded | 3/16" | 1 1/4" | 6063-T52 | Extruded |

| 3/4" x 4" Aluminum Rectangular Bar 6063-T52-Extruded | 3/4" | 4" | 6063-T52 | Extruded |

| 3/4" x 1 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 3/4" | 1 1/2" | 6063-T52 | Extruded |

| 3/8" x 1" Aluminum Rectangular Bar 6063-T52-Extruded | 3/8" | 1" | 6063-T52 | Extruded |

| 3/8" x 1 1/4" Aluminum Rectangular Bar 6063-T52-Extruded | 3/8" | 1 1/4" | 6063-T52 | Extruded |

| 3/8" x 1 1/2" Aluminum Rectangular Bar 6063-T52-Extruded | 3/8" | 1 1/2" | 6063-T52 | Extruded |

| 3/8" x 2" Aluminum Rectangular Bar 6063-T52-Extruded | 3/8" | 2" | 6063-T52 | Extruded |

| 3/8" x 4" Aluminum Rectangular Bar 6063-T52-Extruded | 3/8" | 4" | 6063-T52 | Extruded |

Aluminum Rectangular Bar 6063-T52 Applications

Architectural Structures: Door and window frames, curtain wall supports, decorative trims, fascia panels.

- Industrial Manufacturing: Frames for mechanical equipment, all-aluminum furniture profiles

- Transportation: Lightweight components (may be limited when higher strength T6 condition is required)

- Decorative: Furniture, handrails, signage.

- Electrical: Bus bars and heat sinks in T5/T52/T6 conditions.

- Marine and Outdoor: Lightweight structural components, railings, frames, where aesthetics and corrosion resistance are critical.

- General Manufacturing: Brackets, mounts, enclosures.

Aluminum Rectangular Bar 6063-T52 Key Advantages

The rectangular cross-section provides high structural stability, ideal for modular assembly.

The T52 condition offers moderate strength with low deformation risk, suitable for precision machining scenarios.

Aluminum Rectangular Bar 6063-T52 Manufacturing and Processing

- Extrusion Process: The aluminum bar is produced using a hot extrusion process, where aluminum billets are forced through a die to achieve precise rectangular cross-sections. This process ensures smooth edges and consistent dimensions.

- Surface Treatment: 6063-T52 is known for its architectural-grade surface finish, making it ideal for applications where aesthetics are important. It can be anodized, polished, or coated to enhance durability.

- Customization: Standard lengths (e.g., 6 meters) or custom-cut sizes are available. Thickness ranges from 0.125 inches (3.17 mm) to 4 inches (101.6 mm), with widths up to 12 inches (304.8 mm).

Advantages of Aluminum Rectangular Bar 6063-T52 over Other Alloys

- Versatility: Compared to high-strength alloys like 6061-T6, 6063-T52 is easier to weld, machine, and form into complex shapes.

- Cost Effectiveness: Due to its simpler extrusion process and widespread use, the material cost is lower.

- Corrosion Resistance: Performs exceptionally well in humid or marine environments.

The 6063-T52 rectangular aluminum bar is a versatile and cost-effective solution, ideal for applications requiring formability, corrosion resistance, and aesthetic appeal. Its extruded design and wide availability make it a preferred choice for architectural, electrical, and lightweight structural projects.