7475 T7351 Bar

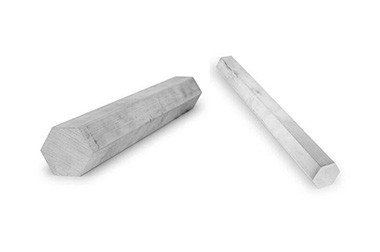

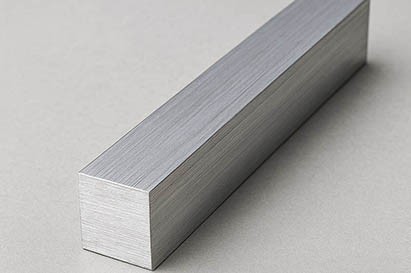

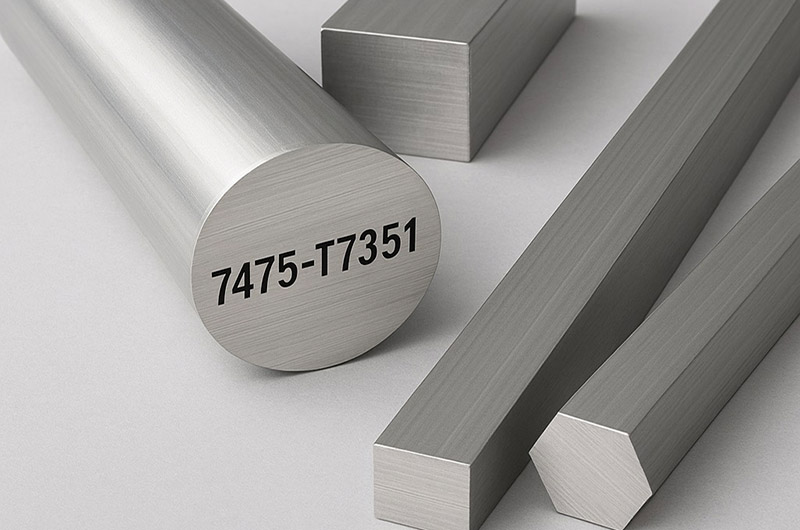

7475 T7351 bars are cylindrical, square, rectangular, or hexagonal aluminum materials made from 7475 aluminum alloy and processed under the T7351 heat treatment condition.

7475-T7351 aluminum bar is a high-strength aerospace-grade alloy known for its excellent fatigue resistance, fracture toughness, and resistance to stress corrosion cracking (SCC). It is particularly suitable for structural applications where durability and reliability are critical.

- Alloy Series: Belongs to the 7000 series aluminum alloys, primarily alloyed with zinc, and may include magnesium, copper, and other elements to form a high-strength structure.

- Heat Treatment Condition: T7351 indicates that the material has undergone solution heat treatment followed by overaging and specific stress relief processes (such as stretching or compressive adjustments) to enhance stress corrosion resistance.

7475 T7351 aluminum bar is a high-strength, precipitation-hardened aluminum alloy mainly used in the aerospace and defense industries, where a combination of strength, fracture toughness, and corrosion resistance is essential.

Haomei 7475 T7351 Bar Specifications

7475-T7351 aluminum bars are manufactured in accordance with stringent aerospace and defense standards. Common specifications include:

- AMS 4202: Covers 7475-T7351 aluminum alloy plate for aerospace applications.

- BSS 7055: Boeing specification for high-strength aluminum alloy plate.

- ASTM B209: Standard specification for aluminum and aluminum-alloy plate.

These specifications ensure that the material meets the mechanical performance and quality standards required for critical applications.

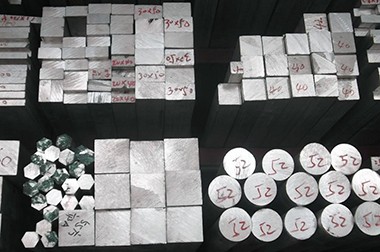

Common Sizes of 7475 T7351 Bar (inches)

7475-T7351 aluminum bars are available in various sizes, typically in plate form that can be machined into required bar dimensions. Common thicknesses and sizes include:

- Thickness: Ranges from 0.75 inches to 3.75 inches

- Width: Typically 48.5 inches

- Length: Up to 144.5 inches

These sizes can be custom cut based on specific requirements.

7475 T7351 Bar Performance Characteristics

Mechanical Properties

- High Strength: Excellent tensile strength, approaching the level of steel

- High Toughness: Suitable for high-load environments

Processing Properties

- Weldable, but process parameters must be controlled

- Suitable for precision cutting and surface treatment

Environmental Adaptability

- Corrosion resistance superior to common aluminum alloys

- Remarkable fatigue resistance, suitable for dynamic load scenarios

7475 T7351 Bar Composition and Condition

7475 Alloy: 7475 aluminum alloy is a derivative of the 7075 series and is a forged aluminum alloy with the following main components:

- Aluminum (Al): ~90.3%

- Zinc (Zn): ~5.7%

- Magnesium (Mg): ~2.3%

- Silicon (Si): ~1.5%

- Chromium (Cr): ~0.22%

T7351 Condition: This condition indicates that the alloy has undergone solution heat treatment, stress relief by stretching, followed by artificial overaging. This specific heat treatment process enhances the alloy's resistance to stress corrosion cracking while maintaining excellent mechanical properties.

7475 T7351 Bar Mechanical Properties

| Property | Value |

| Ultimate Tensile Strength | 530 MPa (76, 000 psi) |

| Yield Strength | 440 MPa (64, 000 psi) |

| Fatigue Strength | 190 MPa (28, 000 psi) |

| Shear Strength | 320 MPa (46, 000 psi) |

| Elongation at Break | 12% |

| Modulus of Elasticity | 70 GPa (10 million psi) |

| Poisson’s Ratio | 0.32 |

| Density | 2.81 g/cm³ (0.102 lb/in³) |

7475 T7351 Bar Thermal and Corrosion Properties

Thermal Stability:

Maximum Operating Temperature: 180°C (350°F).

Thermal Conductivity: 160 W/m-K, suitable for heat dissipation in structural components.

Corrosion Resistance: Enhanced by the addition of chromium and overaging process, but inferior to composite versions.

7475 T7351 Bar Applications

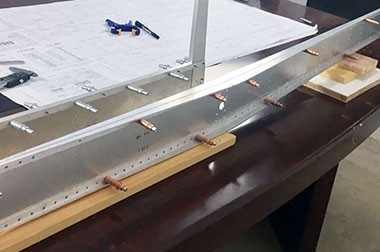

- Aerospace: Load-bearing structural components, aircraft fuselage frames and wing spars, fuselage bulkheads, landing gear components

- Mold Manufacturing: Super-thick mold base materials

- Precision Machinery: High-precision shaft components, transmission parts

- Structural parts requiring high strength and fatigue resistance

- Defense and Automotive: Used for high-stress structural components.

7475 T7351 Bar Key Properties

- Fatigue Resistance: Excellent, making it an ideal choice for components subjected to cyclic loading.

- Corrosion Resistance: Superior resistance to stress corrosion cracking compared to T6 temper; however, anodizing or coating is recommended in harsh environments.

- Strength: Slightly lower than other 7475 tempers, but still provides satisfactory strength and stiffness for various structural applications.

- Toughness: Although slightly lower than some high-strength aluminum alloys, it is sufficient to meet most application requirements.

Comparison Between 7475 T7351 Bar and 7075-T651

Compared with 7075-T651, 7475-T7351 offers the following advantages:

- Higher fracture toughness: Allows better resistance to crack propagation under stress.

- Better resistance to stress corrosion cracking: More durable in corrosive environments.

Comparison Between 7475 T7351 Bar and 7075-T6

Over 40% higher fracture toughness, but slightly lower strength.

- Due to the T7351 tempering process, it offers better stress corrosion resistance.

- Compared with 7050/7150: Comparable fatigue performance but lighter in weight.

7475 T7351 Bar Manufacturing Standards

- Compliant with AMS 4202, ASTM B211, and aerospace-specific certifications (e.g., AS9100).

- Available in both cold-rolled and hot-rolled forms, with thickness customizable for machining or forging needs.

7475 T7351 Bar Main Advantages

- Balanced strength, toughness, and corrosion resistance.

- Suitable for critical aerospace structures subjected to dynamic loads.

You may also be interested in the following

-

7050 7475 Aerospace Aluminum for Wing Attach Structure

Alloys 7050 and 7475 are used in the construction of wing attach structures, ensuring safety and durability during flight.

-

7050 7475 7099 Aircraft Aluminum for Wing Ribs

7050, 7475, and 7099 high-strength aluminum alloys are used to manufacture wing ribs, providing structural support to the wings and enhancing structural integrity.

-

7050 7475 7099 Aerospace Aluminum for Wing Spars

7050, 7475, and 7099 have outstanding strength-to-weight ratios and fatigue resistance, making these high-strength aluminum alloys ideal materials for manufacturing wing spars.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.