7475 T7651 T7351 T651 Aircraft Aluminum Plate

7475 aluminum alloy is a high-strength, high-toughness Al-Zn-Mg-Cu series alloy, recognized as one of the top performers among the 7000 series aluminum alloys. Its main components include aluminum (Al), zinc (Zn), magnesium (Mg), and copper (Cu). This unique combination of elements gives 7475 aluminum alloy excellent comprehensive properties, making it particularly suitable for applications requiring extremely high strength, toughness, and corrosion resistance.

7475 is a toughness-controllable alloy. Compared to 7075 aluminum in the same temper, 7475 aluminum plate typically offers up to 40% higher toughness. Although its overall properties are similar to 7075, 7475 aluminum plate has better corrosion resistance and fatigue characteristics, comparable to or even surpassing similar high-strength aluminum used in the aerospace industry. This product is ideal for applications requiring a combination of high mechanical strength, superior fracture toughness, and resistance to fatigue crack propagation.

7475 aluminum plate is a high-strength forged plate supplied in flat-rolled sheet and thin plate forms. It features excellent fracture toughness, strength-to-weight ratio, and fatigue resistance, while also offering relatively good corrosion resistance, achieving an optimal balance among strength, toughness, and machinability.

7475 alloy is available in both bare and clad forms and is typically annealed to achieve optimal machinability. It is especially suited for applications requiring outstanding mechanical strength, fracture toughness, and resistance to fatigue crack growth, such as aircraft fuselage skins.

There are some key recommendations for use: for corrosion-sensitive applications, T7351/T7651 tempers are recommended; for processing/forming, annealed temper is preferred; in corrosive environments, the Alclad variant can be fully utilized.

7475 Aluminum Plate is an Advanced Aerospace Material

- High strength and toughness: Provides excellent fracture toughness and resistance to fatigue crack growth.

- Fracture toughness: Superior to 7075, especially in stress-intensive environments.

- Corrosion resistance: Moderate; typically supplemented with coatings (e.g., anodizing, primers) or used in controlled environments.

- Custom chemical composition: Controlling zinc, magnesium, copper, and chromium content ensures reliable performance.

- Versatile tempers: Available in various tempers (T651, T7651, T7351) to meet specific application needs.

- Key aerospace applications: Widely used in aircraft components such as wing spars, fuselage walls, and skin due to its excellent strength-to-weight ratio.

Available Tempers and Specification Standards of 7475 Aluminum Alloy

7475 Aluminum Plate Specifications

| Properties | Information |

| Alloy | 7475 |

| Temper | T7651 / T7351 / T651 |

| Thickness Range | 6.35 mm to 152.4 mm (plate form) |

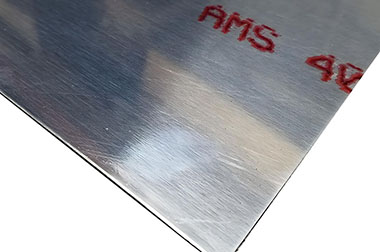

| AMS Standards | AMS 4200 (clad), AMS 4201 (bare) |

| ASTM Standard | ASTM B209 (plate/foil standard) |

7475 Aluminum Plate Standards

Haomei Aluminum offers a variety of aluminum aircraft plate products to meet the needs of various aerospace applications. Our products include a range of standards such as AMS 4041, AMS 4037, AMS 4035, AMS 4049, AMS 4050, AMS 4048, AMS 4045, AMS 4044, AMS 4027, AMS 4026, AMS 4025, AMS 4347, and AMS 4202. Additionally, we provide high-performance aluminum alloys such as 2219, 2124, 7175, 7475, 2024, 7075 T73, and 7075 T76 to meet the demands of aerospace and aviation industry customers.

7475 aluminum alloy complies with a variety of domestic and international standards, mainly including:

AMS (Aerospace Material Specifications)

- AMS 4085: Applicable to 7475-T761 sheet and strip

- AMS 4202: Applicable to 7475-T7351 plate

- AMS 4100: Applicable to Alclad 7475 aluminum plate

U.S. Department of Defense Standards

- DMS 2184: Applicable to 7475 aluminum alloy plate

- DMS 2234: Applicable to Alclad 7475 aluminum plate

Other Standards

- ASTM B594: Applicable to 7475 aluminum alloy rolled plate

- BSS 7055: British Aerospace Standard

- AMS-QQ-A-250/12: Applicable to 7075 and 7475 aluminum alloy plate

- SAE AMS 4050J: Applicable to 7475 aluminum alloy thick plate

International Standards

- ISO R209 AlZn5.5MgCu(A): International Organization for Standardization

- UNS A97475: Unified Numbering System in the U.S.

Chinese Standards

- GB 7475: National Standard of China

- GJB1741A-2018: Chinese Military Standard

Available Tempers of 7475 Aluminum

7475 aluminum alloy is available in a variety of heat treatment tempers to meet the needs of different application scenarios. The main available tempers include:

- 7475 O Temper (Annealed): Fully annealed condition with the best formability and lowest strength, suitable for applications requiring extensive cold working.

- 7475 T6 Temper: Solution heat-treated and artificially aged, providing high strength and hardness, though with relatively lower fracture toughness.

- 7475 T73 Temper: Solution heat-treated and overaged to improve resistance to stress corrosion cracking, with slightly lower strength than the T6 temper.

- 7475 T76 Temper: Solution heat-treated and specially aged, maintaining high strength while offering better fracture toughness and corrosion resistance.

- 7475 T761 Temper: Similar to T76, mainly used in aerospace applications, offering improved toughness and exfoliation corrosion resistance—an enhanced version of the T76 temper.

- 7475 T651/T7651/T7351 Tempers: Heat treatment tempers for thick plate products, where the “51” suffix indicates stress relief by stretching, ensuring uniform property distribution in the material.

- 7475 T7451 Temper: Overaged temper for thick plates, with excellent resistance to stress corrosion cracking.

Among these tempers, T761 and T7351 are the most commonly used tempers of 7475 aluminum alloy in aerospace applications, especially where high fracture toughness and corrosion resistance are required.

We stock 7475 aluminum plates in O or T761 condition. We offer various thicknesses of bare plates or clad plates (the material includes a layer of pure aluminum to enhance corrosion resistance). AMS4100 is the most common specification requirement, and our stock range includes:

| Product | Image | Description |

| 7475 O Clad Aluminum Plate |

|

7475 O condition clad aluminum plate (AMS4100 specification) has lower hardness and higher ductility, making it suitable for aerospace applications that require higher corrosion resistance. The composite layer is made of pure aluminum, which effectively enhances the material's corrosion resistance, especially suitable for harsh environments. |

| 7475 T761 Bare AMS4085 |

|

7475 T761 condition bare aluminum plate meets AMS4085 specification, offering higher strength and tensile performance, commonly used in aerospace fields. This product is heat-treated, providing excellent fatigue resistance and impact resistance. However, compared to T651 condition, its ductility is slightly lower, making it suitable for applications requiring higher structural strength. |

| 7475 T761 Clad AMS4100 |

|

7475 T761 condition clad aluminum (AMS4100 specification) combines the strength of T761 and the excellent corrosion resistance of the clad layer, making it suitable for applications that require both high strength and good corrosion resistance, such as aerospace structural components and skins. |

| 7475 T761 Clad Aluminum Plate |

|

7475 T761 Clad Aluminum Plate offers excellent mechanical properties and corrosion resistance, commonly used for high-performance structural components in the aerospace industry. The pure aluminum composition of the composite layer enhances corrosion resistance, while the T761 condition ensures high strength. |

| 7475 T761 Clad Aluminum Sheet |

|

7475 T761 Clad Aluminum Sheet is a material for high-demand aerospace structural components, particularly suitable for parts that need to withstand high stress in harsh environments. The composite aluminum layer provides excellent corrosion resistance, while the T761 condition enhances the material's strength. |

| 7475-T61 Aluminum Sheet AMS 4084 |

|

7475-T61 aluminum sheet (AMS4084 specification) offers high strength and good impact resistance, commonly used for structural components and high-load-bearing parts in the aerospace industry. Its hardening treatment ensures the material's durability and load-bearing capacity, suitable for applications with strict strength requirements. |

| 7475-T61 Aluminum Sheet Alclad AMS 4207 |

|

7475-T61 aluminum sheet (Alclad AMS 4207 specification) features a composite aluminum alloy layer design, offering excellent corrosion resistance and high strength, commonly used for external structural components in aerospace. The aluminum cladding effectively prevents corrosion, and the T61 condition enhances the strength of the plate, making it suitable for applications in harsh environments. |

| 7475-T651 Aluminum Plate AMS 4090 |

|

7475-T651 aluminum plate (AMS 4090 specification) is heat-treated, offering high strength, corrosion resistance, and good formability. It is commonly used for aerospace structural components that need to withstand large loads. The high strength of this material performs well under high-stress environments, and its corrosion resistance ensures long-term stability. |

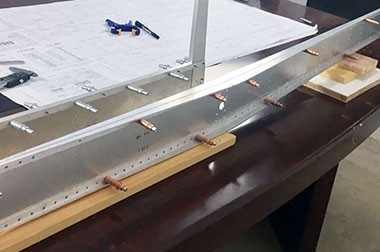

| 7475 Hot Rolling Aluminum Plate |

|

7475 hot-rolled aluminum plate provides excellent mechanical properties and higher strength, widely used for structural components that require higher load-bearing capacity and strength. The hot rolling process ensures the material's stability and uniform performance distribution under high-temperature conditions, making it suitable for aerospace and military industries with high strength requirements. |

| 7475 Cold Rolled Aluminum Plate |

|

7475 cold-rolled aluminum plate is produced using a cold-rolling process, offering good surface quality and dimensional accuracy. The cold-rolled aluminum plate maintains high strength and toughness during processing, suitable for applications that require strict surface flatness and thickness tolerance. It is ideal for high-strength components requiring precision machining in the aerospace industry. |

Specific Product Forms and Corresponding Standards

7475 aluminum alloy is supplied in various product forms, with different forms corresponding to specific tempers and standards:

| Product Form | Common Tempers | Major Standards | Typical Applications |

| Sheet | O, T6, T76, T761 | AMS 4085, DMS 2234 | Fuselage skin, interior panels |

| Plate | T651, T7651, T7351 | AMS 4202, DMS 2184, ASTM B594 | Structural parts, stiffeners |

| Alclad Plate | O, T6, T76, T761 | AMS 4100, DMS 2234 | Areas requiring high corrosion resistance |

| Extrusions | T6, T76, T73 | Custom Standards | Wing beams, frames |

7475 Aluminum Data Sheet

| Feature | Description |

| Alloy Series | 7xxx – high-strength, Zn-Mg-Cu alloys |

| Strength-Toughness | Excellent UTS ~530–590 MPa, 40% ↑ toughness vs. 7075 |

| Fatigue Resistance | Strong resistance to crack propagation |

| Form & Machining | Good machinability/formability in O temper |

| Heat Treatable | Capable of T651/T7351/T7651 tempers |

| Welding | Not recommended, use mechanical/FSW |

| Microstructure | Precipitate strengthened; hot working/recrystallization improve grains |

Advantages of 7475 Aluminum Alloy

High Strength and Lightweight Characteristics

One of the most notable advantages of 7475 aluminum alloy is its outstanding strength-to-weight ratio. Compared to other high-strength aluminum alloys, 7475 has the following features:

- Ultra-high strength: In the T761 temper, 7475 aluminum alloy has a tensile strength of 490–523 MPa (71, 000–76, 000 psi) and a yield strength of up to 421 MPa (61, 000 psi), far surpassing ordinary structural materials.

- Lightweight: Density is approximately 2.81 g/cm³, only about one‑third that of steel, significantly reducing structural weight while maintaining high strength.

- High specific strength: Excellent strength-to-weight ratio, especially suitable for weight-sensitive aerospace applications.

- Thickness advantage: For the same load capacity, 7475 aluminum alloy can use thinner sections, further reducing weight while maintaining sufficient stiffness.

These high strength and lightweight characteristics make 7475 aluminum alloy an ideal choice for aerospace structural components, achieving weight reduction without sacrificing performance.

Excellent Fracture Toughness

Compared to other high-strength aluminum alloys, the greatest advantage of 7475 aluminum alloy lies in its excellent fracture toughness, especially in the short transverse direction:

- High fracture toughness: 7475 aluminum alloy exhibits significantly higher fracture toughness than 7075, especially in the T761 temper, effectively resisting crack propagation.

- Fatigue resistance: Excellent resistance to fatigue crack growth, suitable for structural components subjected to cyclic loading.

- Short-transverse performance: Outstanding elongation and toughness in the short transverse direction, crucial for aerospace structural safety.

- Impact resistance: Can withstand high-energy impacts without brittle fracture, enhancing structural safety and reliability.

This outstanding fracture toughness makes 7475 aluminum alloy particularly suitable for aerospace structures requiring high reliability and safety, such as wing and fuselage components.

Good Corrosion Resistance

When properly treated, 7475 aluminum alloy exhibits good corrosion resistance, especially in T761 and T7351 tempers:

- Exfoliation corrosion resistance: T761-temper 7475 aluminum alloy has very high resistance to exfoliation corrosion, far exceeding T6 temper alloys.

- Stress corrosion cracking resistance: T7351-temper 7475 aluminum alloy has excellent resistance to stress corrosion cracking, suitable for structures exposed to corrosive environments.

- Alclad processing capability: With Alclad (clad aluminum) treatment, surface corrosion resistance can be further improved, suitable for harsh environments.

- Compatibility with protective coatings: Easily combined with various protective coatings to provide additional corrosion protection.

The corrosion resistance of 7475 aluminum alloy enables reliable performance under various environmental conditions, reducing maintenance requirements and extending service life.

Good Machinability

7475 aluminum alloy has good machinability and is suitable for a variety of manufacturing processes:

- Heat treatment responsiveness: Sensitive to heat treatment, allowing attainment of desired mechanical properties through appropriate heat treatment processes.

- Machining performance: In T6 and T76 tempers, it exhibits good cutting performance and can be machined into complex shapes.

- Formability: In the O temper, 7475 aluminum alloy shows good cold formability, suitable for parts requiring complex shaping.

- Weldability: Although its weldability is not as good as some other aluminum alloys, satisfactory weld joints can be achieved with proper welding processes and filler materials.

- Surface treatment adaptability: Easily anodized, chemically conversion coated, etc., enhancing corrosion resistance and aesthetics.

These processing characteristics enable 7475 aluminum alloy to adapt to various manufacturing methods and meet the needs of different applications.

Comparison Advantages Over 7075 Aluminum Alloy

Compared with 7075, another high-strength aluminum alloy, 7475 exhibits the following clear advantages:

- Higher fracture toughness: 7475 aluminum alloy’s fracture toughness is significantly higher than 7075, particularly in the short transverse direction.

- Better fatigue resistance: 7475’s resistance to fatigue crack growth outperforms 7075, suitable for high-cycle load applications.

- Improved corrosion resistance: In the T761 temper, 7475 has better exfoliation corrosion resistance than 7075 in T6 temper.

- Slightly higher strength: In the same temper, 7475’s strength is slightly higher than 7075, especially in thick-section products.

- Better transverse properties: 7475’s properties in the short transverse direction are significantly superior to 7075, which is especially important for large structural parts.

These advantages have led 7475 aluminum alloy to increasingly replace 7075 in high-demand aerospace applications, becoming the preferred high-strength aluminum alloy material.

7475 Aluminium Heat Treatment and Tempers

Common tempers include T651, T7351, and T7651. These tempers undergo solution treatment, quenching, stabilization, and aging to achieve the optimal balance between strength, toughness, and fatigue resistance.

The 7475 alloy comes in several temper names (e.g., T651, T7651, and T7351) that adjust the balance between hardness and toughness:

- T7651 (AMS 4089): High overage for maximum stress‐corrosion cracking resistance

- T7351 (AMS 4202): Intermediate overage for balance of strength and corrosion resistance

- T761 (AMS 4100): Clad for corrosion protection on one or both surfaces

- T651: Solution‐heat‐treated, stress‐relieved

Each temper tailors the microstructure to optimize fracture toughness, fatigue endurance, and SCC resistance.

7475 aluminum plate is primarily produced in rolled form, suitable for further processing, forming, and heat treatment operations to tailor its performance for specific structural applications.

7475 aluminum alloy is generally used for structural components that require high strength and low weight. 7475 T7651 and T7351 are two commonly used aluminum alloys, widely applied in high-strength demanding fields such as aerospace.

7475 t7651 and T7351 are two commonly used aluminum alloy materials, widely applied in aerospace and other high-strength requirement fields.

Below is a comparison table for 7475-T7651 and 7475-T7351 aerospace aluminum alloy plates:

| Characteristic | 7475-T7651 Aerospace Aluminium Plate Sheet | 7475-T7351 Aerospace Aluminium Plate Sheet |

| Alloy System | Al-Zn-Mg-Cu | Al-Zn-Mg-Cu |

| Main Features | High strength, good toughness, and crack resistance | High strength, good crack propagation resistance, and fatigue performance |

| Heat Treatment Condition | T7651 (Strengthened condition) | T7351 (Mild heat-treated condition) |

| Strength | Very high, suitable for high-load-bearing components | High, suitable for components under high stress and complex loads |

| Toughness and Crack Resistance | Good crack resistance and toughness | Better crack propagation resistance, suitable for long-term high-strength applications |

| Corrosion Resistance | Excellent | Excellent |

| Fatigue Performance | Good | Excellent, suitable for components requiring high fatigue resistance |

| Main Applications | Aircraft fuselage, wing frames, spars, and other structural components | Aircraft wing spars, fuselage frames, heavy-load structural components |

| Applicable Fields | Aerospace, especially for parts requiring high strength and crack resistance | Aerospace, suitable for high-strength and fatigue-resistant structural components |

7475 Aluminium Sheet Corrosion and Durability

- Stress Corrosion Cracking (SCC): Mitigated by T73/T76 tempering.

- Coatings: Anodized or aluminum cladding, providing additional protection in harsh environments.

Stress Corrosion Cracking (SCC) of 7475 Aluminium Sheet

7475 aluminum alloy sheets, when subjected to stress corrosion cracking (SCC), can effectively mitigate this issue through T73 and T76 tempering. These two heat treatment states optimize the alloy's lattice structure, thereby reducing the risk of crack propagation due to chloride corrosion in high-stress environments. The T73 and T76 temper provide higher corrosion resistance and crack resistance, making the alloy sheet ideal for aerospace applications, especially where high strength and corrosion resistance are critical.

Coating Protection of 7475 Aluminium Sheet

7475 aluminum alloy sheets can be treated with anodizing or aluminum cladding to gain additional protection in harsh environments. Anodizing forms a strong oxide film on the surface of the alloy, enhancing its corrosion resistance and wear resistance, making it particularly suitable for aerospace, military, and other applications requiring strong resistance to corrosive environments. The aluminum cladding provides extra protection, effectively preventing oxidation, corrosion, and other environmental damage to the surface, prolonging the material's service life and maintaining its structural integrity.

7475 t7651 T7351 Aircraft Aluminum Plate Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 7475 | 0.10 | 0.12 | 1.2-1.9 | 0.06 | 1.9-2.6 | 0.18-0.25 | 5.2-6.2 | 0.06 | 0.05 | GB/EN/AMS |

7475 t7651 T7351 Aircraft Aluminum Plate Mechanical Properties

| Alloy | Temper | Thickness(mm) |

Tensile strength(mm) RM(Mpa) |

Yield strength RP0.2(Mpa) |

Breaking elongation A50% |

Standard |

| 7475 | O | 0.5-4.0 | 185-205 | 90-110 | 18-22 | GB/EN/AMS |

Properties vary by temper, with T651 offering peak strength and T7351/T7651 prioritizing toughness:

| Property | T651 | T7351 | T7651 |

| Tensile Strength | 78 ksi (531 MPa) | 76 ksi (531 MPa) | 77 ksi (531 MPa) |

| Yield Strength | 68 ksi (462 MPa) | 67 ksi (462 MPa) | 67 ksi (462 MPa) |

| Elongation | 9% | 12% | 12% |

| Hardness (Brinell) | 140 | 135 | 140 |

| Fracture Toughness | High | Very High | Superior |

- T651: High strength, suitable for wing spars and bulkheads.

- T7351/T7651: Optimized for stress corrosion resistance (e.g., fuselage skins).

- Alclad variant: Pure aluminum cladding enhances corrosion resistance of thin plates.

Haomei hot selling 7475 aerospace aluminum plate products

7475 aluminum alloy is available in various heat treatment states, each imparting different performance characteristics to the alloy, thus meeting different application requirements.

7475 T651 Aircraft Aluminum Plate

Heat Treatment State (T651): The 7475 aluminum alloy plate in T651 condition undergoes solution treatment followed by stress relieving, retaining excellent strength and toughness. This state of the alloy is suitable for aerospace applications requiring high strength and toughness.

Characteristics:

- High Strength: The 7475 aluminum alloy in T651 condition provides extremely high mechanical strength, suitable for parts subjected to high loads.

- Toughness and Crack Propagation Resistance: After appropriate heat treatment, the T651 condition retains good toughness, effectively resisting crack propagation, thus increasing the durability of parts.

- Good Machinability: Due to the stress relief, T651 aluminum alloy does not undergo deformation during machining, helping to ensure the precision of complex parts.

Applications:

Used in high-stress structural components such as aircraft fuselage, wing skins, and wing parts.

Suitable for parts requiring high strength and fatigue resistance, such as airframe frames and spars.

7475 T7351 Aircraft Aluminum Plate

Heat Treatment State (T7351): The 7475 aluminum alloy in T7351 condition offers high strength and good toughness, having undergone a special aging treatment. This state is suitable for applications with medium to high strength requirements, especially for components needing high fatigue resistance and toughness.

Characteristics:

- High Fatigue Resistance: The T7351 condition has excellent fatigue resistance, making it suitable for structures subjected to repeated loads over extended periods.

- Fracture Toughness: Compared to T651, T7351 offers enhanced crack propagation resistance and fracture toughness, making it ideal for aerospace components requiring high toughness.

- Corrosion Resistance: The T7351 condition performs well in corrosion resistance, especially for components exposed to the harsh environments of aircraft.

Applications:

Used in medium-to-high strength structural components for aircraft, such as wing frames, spars, and cockpit structures.

Particularly suitable for load-bearing parts in aircraft and components that require high fatigue performance.

7475 T7651 Aircraft Aluminum Plate

Heat Treatment State (T7651): The 7475 aluminum alloy in T7651 condition undergoes a special heat treatment process, mainly through aging and temperature control, to optimize the alloy’s strength and toughness. This condition offers very high strength and excellent crack propagation resistance.

Characteristics:

- Extremely High Strength: The 7475 aluminum alloy in T7651 condition is used in applications requiring ultra-high strength, suitable for parts subjected to extreme load conditions.

- Fatigue and Crack Propagation Resistance: Compared to other alloy states, T7651 provides superior fatigue resistance and crack propagation resistance, making it ideal for aerospace parts that require long-term reliability under high stress.

- Good Corrosion Resistance: The T7651 condition retains good corrosion resistance, making it suitable for use in complex environments.

Applications:

Used in high-strength aerospace structural components such as aircraft wing beams, fuselage frames, and wing skins, which require extremely high strength.

Suitable for key flight structures requiring superior crack propagation resistance, strength, and toughness.

The following table introduces the main characteristics and application ranges of 7475 aluminum alloy in T651, T7351, and T7651 conditions.

| Temper | Characteristics | Application Range |

| 7475 T651 | Provides high strength and good machinability | Suitable for high-stress parts |

| 7475 T7351 | Provides better fatigue performance and crack propagation resistance | Suitable for components subjected to repeated loads |

| 7475 T7651 | Provides extremely high strength and excellent fatigue resistance | Suitable for high-strength aerospace components under extreme load conditions |

7475 Alloy Common Trade Names

UNS A97475, ISO AlZn5.5MgCu(A), AA7475-T7351, Al7475-T7351

Applications of 7475 Aluminum in Aerospace

Main Application Areas and Product Forms of 7475 Aluminum

Due to its excellent properties, 7475 aluminum alloy is widely used in aerospace, mainly in the following areas:

Fuselage Structure

- Fuselage skin: Using T761-temper Alclad 7475 sheet for high strength and corrosion resistance.

- Frames and stringers: T761-temper extrusions or forgings providing structural support.

- Floor beams and floor supports: T7351-temper thick plate for high strength and fatigue resistance.

Wing Structure

- Wing skin: T761-temper Alclad sheet providing high tensile strength and fracture toughness.

- Wing spars and ribs: T7351-temper thick plate or extrusions providing structural strength and stiffness.

- Flap and aileron structures: T761-temper thin plate and extrusions offering lightweight, high-strength solutions.

Tail Structure

- Horizontal and vertical tail skin: T761-temper thin plate offering required strength and stiffness.

- Tail spars and ribs: T7351-temper thick plate and extrusions providing structural support.

Other Critical Areas

- Landing gear doors and structure: T7351-temper thick plate for high stress-corrosion resistance.

- Engine mounting structures: T761-temper forgings offering high strength and impact resistance.

- Pressurization frames: T7351-temper thick plate for high strength and sealing.

In aerospace, 7475 aluminum alloy is mainly used in the form of sheet, plate, extrusions, and forgings, with Alclad products used where additional corrosion resistance is needed.

Recommended Tempers for 7475 Aluminum in Aerospace Applications

In aerospace use, the choice of temper for 7475 aluminum alloy depends on the requirements of the specific application area:

| Application Area | Recommended Temper | Product Form | Main Advantage |

| Fuselage Skin | T761 | Thin sheet (Alclad) | High strength, high toughness, corrosion resistance |

| Wing Spars/Ribs | T7351 | Thick plate, extrusions | Stress-corrosion resistance, high strength |

| Tail Structures | T761 | Thin sheet, mid-thick plate | Lightweight, high strength, good toughness |

| Landing Gear Doors | T7351 | Thick plate | Stress-corrosion resistance, high strength |

| Interior Structures | O, T6 | Thin sheet | Ease of machining, good aesthetics |

Hot selling 7475 aluminum plate size list

| Description | Thickness | Size | Temper |

| 1.00" x 12" x 12" 7475 aluminum plate | 1.00" | 12" x 12" | t7351 |

| 1.00" x 18" x 12" 7475 aluminum plate | 1.00" | 18" x 12" | t7351 |

| 1.00" x 18" x 18" 7475 aluminum plate | 1.00" | 18" x 18" | t7351 |

| 1.00" x 12" x 24" 7475 aluminum plate | 1.00" | 12" x 24" | t7351 |

| 1.00" x 12" x 36" 7475 aluminum plate | 1.00" | 12" x 36" | t7351 |

| 1.00" x 24" x 24" 7475 aluminum plate | 1.00" | 24" x 24" | t7351 |

| 1.00" x 24" x 36" 7475 aluminum plate | 1.00" | 24" x 36" | t7351 |

| 1.00" x 36" x 36" 7475 aluminum plate | 1.00" | 36" x 36" | t7351 |

| 1.00" x 48" x 24" 7475 aluminum plate | 1.00" | 48" x 24" | t7351 |

| 1.00" x 48" x 36" 7475 aluminum plate | 1.00" | 48" x 36" | t7351 |

| 1.00" x 48" x 48" 7475 aluminum plate | 1.00" | 48" x 48" | t7351 |

| 1.00" x 48" x 144" 7475 aluminum plate | 1.00" | 48" x 144" | t7351 |

| 1.75" x 12" x 12" 7475 aluminum plate | 1.75" | 12" x 12" | t7351 |

| 1.75" x 18" x 12" 7475 aluminum plate | 1.75" | 18" x 12" | t7351 |

| 1.75" x 18" x 18" 7475 aluminum plate | 1.75" | 18" x 18" | t7351 |

| 1.75" x 12" x 24" 7475 aluminum plate | 1.75" | 12" x 24" | t7351 |

| 1.75" x 12" x 36" 7475 aluminum plate | 1.75" | 12" x 36" | t7351 |

| 1.75" x 24" x 24" 7475 aluminum plate | 1.75" | 24" x 24" | t7351 |

| 1.75" x 24" x 36" 7475 aluminum plate | 1.75" | 24" x 36" | t7351 |

| 1.75" x 36" x 36" 7475 aluminum plate | 1.75" | 36" x 36" | t7351 |

| 1.75" x 48" x 24" 7475 aluminum plate | 1.75" | 48" x 24" | t7351 |

| 1.75" x 48" x 36" 7475 aluminum plate | 1.75" | 48" x 36" | t7351 |

| 1.75" x 48" x 48" 7475 aluminum plate | 1.75" | 48" x 48" | t7351 |

| 1.75" x 48" x 144" 7475 aluminum plate | 1.75" | 48" x 144" | t7351 |

| 3.00" x 12" x 12" 7475 aluminum plate | 3.00" | 12" x 12" | t7351 |

| 3.00" x 18" x 12" 7475 aluminum plate | 3.00" | 18" x 12" | t7351 |

| 3.00" x 18" x 18" 7475 aluminum plate | 3.00" | 18" x 18" | t7351 |

| 3.00" x 12" x 24" 7475 aluminum plate | 3.00" | 12" x 24" | t7351 |

| 3.00" x 12" x 36" 7475 aluminum plate | 3.00" | 12" x 36" | t7351 |

| 3.00" x 24" x 24" 7475 aluminum plate | 3.00" | 24" x 24" | t7351 |

| 3.00" x 24" x 36" 7475 aluminum plate | 3.00" | 24" x 36" | t7351 |

| 3.00" x 36" x 36" 7475 aluminum plate | 3.00" | 36" x 36" | t7351 |

| 3.00" x 48" x 24" 7475 aluminum plate | 3.00" | 48" x 24" | t7351 |

| 3.00" x 48" x 36" 7475 aluminum plate | 3.00" | 48" x 36" | t7351 |

| 3.00" x 48" x 48" 7475 aluminum plate | 3.00" | 48" x 48" | t7351 |

| 3.00" x 48" x 144" 7475 aluminum plate | 3.00" | 48" x 144" | t7351 |

| 3.75" x 12" x 12" 7475 aluminum plate | 3.75" | 12" x 12" | t7351 |

| 3.75" x 18" x 12" 7475 aluminum plate | 3.75" | 18" x 12" | t7351 |

| 3.75" x 18" x 18" 7475 aluminum plate | 3.75" | 18" x 18" | t7351 |

| 3.75" x 12" x 24" 7475 aluminum plate | 3.75" | 12" x 24" | t7351 |

| 3.75" x 12" x 36" 7475 aluminum plate | 3.75" | 12" x 36" | t7351 |

| 3.75" x 24" x 24" 7475 aluminum plate | 3.75" | 24" x 24" | t7351 |

| 3.75" x 24" x 36" 7475 aluminum plate | 3.75" | 24" x 36" | t7351 |

| 3.75" x 36" x 36" 7475 aluminum plate | 3.75" | 36" x 36" | t7351 |

| 3.75" x 48" x 24" 7475 aluminum plate | 3.75" | 48" x 24" | t7351 |

| 3.75" x 48" x 36" 7475 aluminum plate | 3.75" | 48" x 36" | t7351 |

| 3.75" x 48" x 48" 7475 aluminum plate | 3.75" | 48" x 48" | t7351 |

| 3.75" x 48" x 144" 7475 aluminum plate | 3.75" | 48" x 144" | t7351 |

7475 Aluminum Machinability Characteristics

- Machinability: Excellent in annealed (O) temper; oil-based lubricants yield the best results.

- Formability: Easily cold-worked in annealed temper; exhibits springback in T tempers.

- Weldability: Poor to nonexistent; prone to hot cracking—typically joined using mechanical fasteners or friction stir welding.

- Hot Workability: Suitable for hot spinning and forming after preheating.

7475 Aluminum Strength, Toughness, and Fatigue Performance

- Tensile strength is comparable to 7075, but fracture toughness is improved by approximately 40%.

- Excellent fatigue crack resistance—critical for aerospace structural components.

7475 Aluminum Limitations

- Weldability: Poor; not recommended for welded assemblies.

- Temperature Sensitivity: Strength declines above 180°C (350°F).

- Corrosion: Prone to stress corrosion in T6xx tempers; T7xxx tempers or Alclad versions help mitigate.

7475 Aluminum Plate Quality and Testing

- Non-Destructive Testing (NDT): Ultrasonic inspection for internal defects.

- Certification: Mill Test Reports (MTRs) to ensure compliance with aerospace standards.

Precautions for Purchasing 7475 Aluminum Sheet Plate

| Category of Purchasing Precautions | Subcategory | Key Points |

| Supplier Selection and Qualification | Supplier Qualification | Must be certified to ISO 9001/AS9100; preference for suppliers with experience in aerospace 7475 supply; production capacity must meet demand |

| Material Traceability | Provide complete quality certificates (composition, performance reports); full traceability of batches; aerospace-grade must meet AMS/ASTM standards | |

| Specification and Temper Confirmation | Temper Confirmation | Clearly specify heat treatment temper (e.g. T761/T7351); select temper based on application (T761 for high toughness, T7351 for corrosion resistance) |

| Specification Standards | Comply with specified standards (e.g. AMS 4085/4202); define dimensional tolerances and surface quality requirements | |

| Quality Inspection and Acceptance | Appearance Inspection | No cracks, scratches, or defects; surface treatment layer must be complete and uniform; consistent color |

| Dimensional Inspection | Thickness / width / length must meet tolerances; flatness and straightness must be up to standard | |

| Storage and Transportation | Storage Environment | Dry and well-ventilated; temperature 15–25°C; dust protection |

| Packaging Protection | Moisture-proof packaging (for sea transport / long-term storage); layered separation to prevent scratching; edge protection for thin/mid-thick plates | |

| Cost and Cost-Effectiveness | Material Cost | Compare base price and processing fees; consider bulk discounts; confirm any surcharges for special specifications |

| Processing Cost | Consider cutting / heat treatment difficulty; control machining allowance reasonably; include surface treatment (e.g. anodizing) costs |

Applications of 7475 Aluminum Alloy in Non-Aerospace Fields

Applications in Transportation

In addition to aerospace, 7475 aluminum alloy is widely used in the transportation sector:

High-Speed Trains

- Car body structures: Use T761-temper thin sheets and extrusions to reduce weight and improve structural strength

- Bogie components: Use T7351-temper thick plates and forgings to provide high strength and fatigue resistance

- Brake system components: Utilize its high strength and good thermal conductivity

Automotive Industry

- Racing and high-performance vehicles: Used in chassis components, suspension systems, and body structures to reduce weight and enhance performance

- Commercial vehicles: Used in truck and bus structural components, frames, and load-bearing parts

- Special-purpose vehicles: Such as armor panels and structural parts for bulletproof and rescue vehicles

Marine and Offshore Engineering

- High-speed boats and racing boats: Use T761-temper thin sheets and extrusions to reduce weight and improve strength

- Ship structures: Used in decks, bulkheads, and superstructures to provide high strength and corrosion resistance

- Offshore platforms: Used for corrosion-resistant structural components, especially in seawater environments

Sports Equipment

7475 aluminum alloy also has unique applications in sports equipment and high-end consumer products:

- Bicycles: 7475 used in frames, handlebars, and other components for lightweight and high strength

- Golf clubs: Used in club heads and shafts to provide high ball speed and control performance

- Skis and ski poles: 7475 used to manufacture lightweight and high-strength ski equipment

- Tennis and badminton rackets: Used in frames and handles to provide high strength and good elasticity

Military Applications

7475 aluminum alloy also plays a significant role in military and defense applications:

- Light armored vehicles: Use T761-temper thick plates and composite armor systems to provide ballistic and blast protection

- Armored personnel carriers and infantry fighting vehicles: Used for vehicle armor and protective structures

- Mine-resistant vehicles: Used for bottom armor and V-shaped hull structures to provide blast protection

Construction and Structural Engineering

- Long-span roof structures: Use T761-temper extrusions and plates to provide lightweight, high-strength solutions

- Building curtain walls: Used for high-strength frames and decorative parts, offering aesthetic and structural performance

- Bridge structures: Used for lightweight bridge components, especially where weight reduction is required

7475 Aluminum vs. 2024 Alloys

Compared to 7075: 7475 offers better fracture toughness and stricter impurity control, improving reliability in critical applications.

Compared to 2024: Has higher strength but lower corrosion resistance; typically used in weight-critical designs.

| Comparison | 7475 Aluminum vs. 7075 Aluminum | 7475 Aluminum vs. 2024 Aluminum |

| Strength | The strength of 7475 aluminum is similar to that of 7075, both being high-strength alloys. | 7475 aluminum has higher strength than 2024, giving it an advantage in high-load applications. |

| Fracture Toughness | 7475 aluminum has superior fracture toughness, mainly due to its more stringent metallurgical control and optimized alloy composition, which enhances its reliability in high-stress and high-fatigue life applications. | 7475 aluminum has relatively high fracture toughness, while 2024 aluminum has moderate toughness, which may not be as suitable for structural components with high fatigue life requirements. |

| Impurity Control | 7475 aluminum has stricter impurity control, which reduces the impact of impurities on material performance, improving stability and reliability. | 7475 aluminum also has strict impurity control, while 2024 aluminum has relatively looser metallurgical control, which may lead to more performance variation in extreme environments. |

| Corrosion Resistance | 7475 aluminum has similar corrosion resistance to 7075, both requiring additional corrosion protection measures such as surface treatments or coatings. | 7475 aluminum has worse corrosion resistance than 2024 aluminum and is more susceptible to corrosion in exposed environments, requiring additional protective treatment, while 2024 aluminum has better natural corrosion resistance in ambient conditions. |

| Application Areas | 7475 aluminum is more suitable for aerospace structures requiring high fracture toughness, such as fuselage frames, wing components, and other components subjected to high fatigue loads. | 7475 aluminum is primarily used in weight-critical designs such as aerospace structures, while 2024 aluminum is commonly used in aerospace and military applications where corrosion resistance is more important, such as skin and load-bearing frames. |

7475 aluminium sheet is frequently used in aircraft fuselage skins. As a 7000 series alloy, it shares many of the same characteristics as 7075 but has notably higher fracture toughness.

7475 alloy aluminium sheet is a controlled toughness alloy, offering 40% higher toughness than 7075 alloy under the same tempering conditions. Its corrosion resistance and fatigue behavior are also equal to or better than many other high-strength aerospace alloys, making it ideal for applications requiring high strength, excellent fracture toughness, and resistance to fatigue crack propagation.

Special Considerations

- Stress Relief: Recommended after forming to prevent distortion.

- Surface Treatment: Alclad variants available to enhance corrosion resistance.

7475 aluminum plate is the ideal choice for critical applications demanding high strength, high toughness, and high reliability. Its optimized composition and processing make it an indispensable material in aerospace and advanced engineering fields. Proper handling, manufacturing techniques, and protective measures ensure optimal performance in real-world applications.

You may also be interested in the following

-

7050 7475 Aerospace Aluminum for Wing Attach Structure

Alloys 7050 and 7475 are used in the construction of wing attach structures, ensuring safety and durability during flight.

-

7050 7475 7099 Aircraft Aluminum for Wing Ribs

7050, 7475, and 7099 high-strength aluminum alloys are used to manufacture wing ribs, providing structural support to the wings and enhancing structural integrity.

-

7050 7475 7099 Aerospace Aluminum for Wing Spars

7050, 7475, and 7099 have outstanding strength-to-weight ratios and fatigue resistance, making these high-strength aluminum alloys ideal materials for manufacturing wing spars.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.