7055 T7751 Aerospace Aluminum Sheet Plate

7055 aluminum is a high-strength alloy primarily composed of aluminum, zinc, and small amounts of magnesium and copper. It belongs to the 7000 series aluminum alloys and is renowned for its excellent strength-to-weight ratio, making it widely used in aerospace, military vehicles, and other high-performance structures.

7055 aluminum alloy is a heat-treatable high-strength aluminum alloy, with ultimate tensile strength surpassing that of 7150 aluminum alloy. While maintaining excellent tensile strength, it also exhibits good fracture toughness and stress corrosion resistance. This makes it one of the most advanced commercial high-strength aluminum alloys available on the market.

As a high-performance alloy, 7055 aluminum’s high strength, outstanding toughness, and corrosion resistance make it particularly suitable for fields such as aerospace that demand high strength and reliability. Additionally, the alloy also possesses excellent compressive strength, enabling it to withstand heavy loads and maintain stable performance in complex working environments.

7055 aluminum not only has broad application prospects in the aerospace industry but also demonstrates potential in other high-strength industrial fields due to its superior mechanical properties and stress corrosion resistance, making it an ideal choice for widespread engineering applications.

7055 aluminum is renowned for its exceptional strength-to-weight ratio and is the material of choice in aerospace and other high-performance industries. This alloy is primarily used in aircraft wings, fuselage components, and landing gear—critical load-bearing structures where strength and durability are paramount.

7055 aluminum plate is an ultra-hard aluminum alloy material characterized mainly by its high strength, corrosion resistance, and excellent processing performance.

Specification of 7055 Aerospace Aluminum Alloy

| Alloy | Temper | Thickness(mm) | Width(mm) |

| 7055 | T7751 | 4-260 | 1200-3800 |

Properties of 7055 Aerospace Aluminum Plate

- High Strength: 7055 aluminum offers outstanding strength, sometimes even exceeding that of 7075. It has higher static and fatigue strength compared to 7075 and 7050.

- Corrosion Resistance: With the addition of copper and other elements, 7055 aluminum offers better corrosion resistance than some other 7000 series alloys, making it less susceptible to stress corrosion cracking (SCC).

- Fatigue Resistance: This alloy has good fatigue strength, meaning it can withstand repeated stress and strain without failure.

- Heat Treatable: It is a heat-treatable alloy whose mechanical properties can be adjusted through specific heat treatment processes.

- Formability: The alloy can be processed into various forms including plates, sheets, and extrusions, making it suitable for different manufacturing processes.

- Poor Weldability: Like many high-strength aluminum alloys, 7055 is difficult to weld; welding can reduce its strength.

- Good Machinability: Suitable for cutting, forming, and heat treatment.

- Strong Heat Treatment Capability: Common tempers include T7751, T7451, T7651, etc.

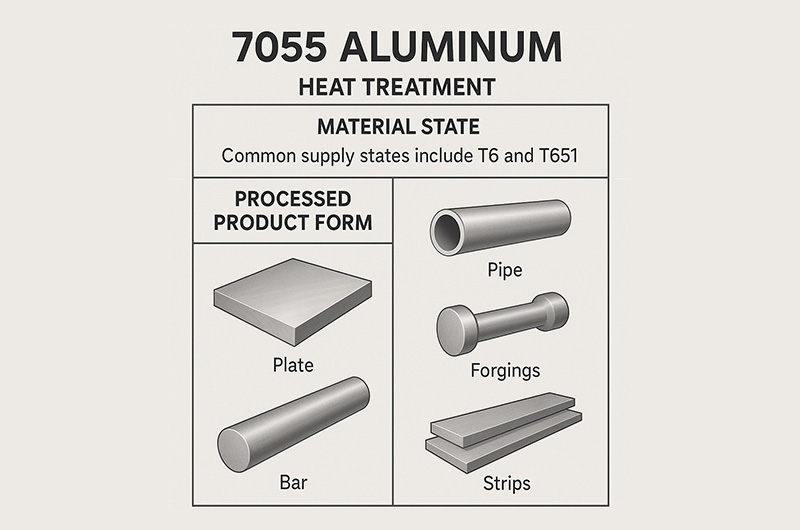

7055 Aluminum Heat Treatment and Product Forms

7055 Aluminum Tempers

Common supply tempers include T6, T651 (solution heat-treated and artificially aged), which further enhance mechanical properties.

| Temper | Description |

| 7055-T6 | 7055-T6 aluminum alloy products are widely used in aerospace structures due to their outstanding strength and good corrosion resistance. This temper is achieved through solution heat treatment followed by full artificial aging, allowing the precipitation strengthening phases to fully form within the material and thereby reach extremely high tensile and yield strengths. 7055-T6 aluminum alloy products are especially suitable for main load-bearing structural parts with high strength requirements, such as aircraft wing beams, landing gear components, and connecting nodes. However, its toughness and resistance to stress corrosion cracking are relatively lower, thus requiring careful consideration in design. |

| 7055-T651 | 7055-T651 aluminum alloy products are stress-relieved by stretching based on the T6 condition, enhancing dimensional stability and machining precision. This temper not only retains the high strength of T6 but also significantly reduces residual stresses caused by heat treatment, helping to minimize deformation during machining. 7055-T651 aluminum alloy products are commonly used for large aerospace structural components, such as aircraft mid-fuselage sections, fuselage frames, and high-load door assemblies, ensuring high strength while offering good machinability and finished product stability. |

7055 Aluminum Product Forms

Can be produced as plate, bar, tube, forging, strip, with thicknesses ranging from 1mm to 500mm. Supports custom specifications including extra-wide (up to 8 meters) and extra-long dimensions.

| Product Form | Description |

| 7055 Aluminum Plate | 7055 aluminum plate features extremely high strength and excellent stress corrosion resistance, making it a key material for primary load-bearing structures in modern aerospace. This product can be manufactured in thicknesses ranging from 1mm to 500mm and supports custom extra-wide formats up to 8 meters. It is widely used in aircraft skins, wing panels, bulkheads, fairings, and other large structural components, enabling integrated forming and precision machining of oversized parts. |

| 7055 Aluminum Bar | 7055 aluminum bar is widely used in the production of aerospace connectors, fasteners, structural supports, and other high-load parts due to its excellent mechanical properties—especially high static strength and good machinability. The bar can be customized to different diameters and lengths according to customer requirements, ensuring it meets the machining demands of high-strength structural components. It is particularly suitable for precision turning and CNC machining of high-performance parts. |

| 7055 Aluminum Tube | 7055 aluminum tube combines light weight, high strength, and good fatigue resistance, making it suitable for aerospace system pipelines, structural supports, and mechanical frameworks requiring both strength and lightweight. This product offers excellent specific strength and machinability, and can be produced using extrusion, cold drawing, and other methods to achieve various dimensions. It also supports custom extra-long tubes for special structural installations. |

| 7055 Aluminum Forging | 7055 aluminum forgings are widely used in critical aerospace components subject to high loads and strong impacts, such as landing gear, connecting hinges, and engine mounts, due to their dense structure and highly consistent mechanical properties. These products can be manufactured through die forging, open-die forging, and other methods, offering good mechanical isotropy. They also support the custom production of various complex shapes and large integral forgings. |

| 7055 Aluminum Strip | 7055 aluminum strip offers controlled thickness, excellent surface quality, and consistent performance, making it advantageous for lightweight applications such as aircraft skin, cladding materials, reinforcement layers, and electronic structural parts. The strip can be rolled down to 1mm thickness while maintaining good flatness and corrosion resistance, and is suitable for a variety of winding, stamping, and bonding processes. |

7055 Aerospace Aluminum Alloy Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 7055 | 0.10 | 0.15 | 2.0-2.6 | 0.05 | 1.8-2.3 | 0.04 | 7.6-8.4 | 0.08-0.25 | 0.06 | GB/AMS/EN |

Aluminum 7055 Plate Properties

| Properties | SI Unit |

| Density | 2.86 g/cm3 |

| Ultimate Tensile Strength | 593 MPa |

| Elongation at Break | 9.0% to 12.0% |

| Fracture Toughness | 24.2 MPa-m½ |

7055 Aerospace Aluminum Alloy Mechanical Properties

| Alloy | Temper | Direction | Thickness(mm) |

Tensile Strength Rm(Mpa) |

Yield Strength RP0.2(Mpa) |

Breaking Elongation A50% |

Standard |

| 7055 | T7751 | LT | 6-38 | 635 | 590-610 | 8-10 | AMS4206A |

Aluminum 7055 T7751 Plate

Aluminum 7055 T7751 Plate is a high-strength, heat-treatable aluminum alloy, specifically designed for applications requiring superior mechanical properties and excellent resistance to stress corrosion cracking. The T7751 temper represents a specific heat treatment process that optimizes both strength and toughness, making it a preferred material in aerospace and other high-performance sectors.

| Feature | Description |

| High Strength | Ultimate tensile strength (UTS) around 593 MPa (86 ksi), one of the highest-strength aluminum alloys. |

| Good Toughness | Maintains good fracture toughness, providing impact resistance, especially important in aerospace. |

| Stress Corrosion Resistance | Excellent resistance to stress corrosion cracking (SCC), ensuring durability in highly stressed environments. |

| Fatigue Resistance | Outstanding fatigue properties, crucial for components under cyclic loading, such as aircraft structures. |

| Heat Treatable | Can be heat-treated to achieve optimal mechanical properties. The T7751 temper enhances strength and resistance to cracking. |

7055 T7751 aluminum plate is an ideal choice for high-performance applications, especially in the aerospace industry where strength, toughness, and corrosion resistance are critical. Its outstanding mechanical properties, combined with its ability to resist stress corrosion cracking, make it a highly sought-after material for critical high-stress components.

7055 Aluminum Plate Aerospace Applications

Aerospace: 7055 aluminum is widely used in aircraft structures, particularly for upper wing skins and other high-stress components.

Military: Due to its high strength and corrosion resistance, it is also used in military hardware.

High-Performance Applications: Suitable for parts requiring lightweight and high mechanical performance, such as automotive components and sports equipment.

Due to its high strength and corrosion resistance, 7055 aluminum plate is widely used in aerospace structures, including:

- Upper wing skins

- Horizontal stabilizers

- Keel beams

- Seat tracks

- Cargo rails

Its application in these components helps reduce aircraft weight, improve fuel efficiency, and enhance structural integrity.

Wing Skins

7055 aluminum alloy is commonly used for aircraft wing skins due to its exceptional strength and stiffness. It effectively resists warping and deformation under aerodynamic loads during flight, ensuring the aerodynamic performance and structural integrity of the wings. Additionally, its good fatigue strength makes it suitable for high-frequency flight operations, extending the wing's lifespan.

Fuselage Structures

In aircraft fuselage structures, 7055 aluminum alloy is often used for manufacturing frames and skins. Its high strength and low density significantly reduce the overall weight while maintaining strength, thereby improving fuel efficiency and payload capacity. Moreover, its corrosion resistance and oxidation resistance make it suitable for various extreme environments, enhancing the fuselage's reliability and durability.

High-Stress Components

7055 aluminum alloy is well-suited for manufacturing high-stress components such as landing gear and engine mounts. These parts endure significant impacts and loads during flight and landing, and the strength and toughness of 7055 ensure their stability and safety in high-pressure environments. Its excellent machinability also allows for the production of complex shapes and structures, ensuring design flexibility.

Other Fields of Application for 7055 Aluminum Plate

- Military: Due to its corrosion resistance, it can be used in armored vehicles, helicopters, and naval vessels

- Automotive: Used in the production of high-performance components such as gears and shafts to reduce weight

What is the difference between 7075 and 7055 aluminum?

- Heat Treatability: 7055 is heat-treatable and its mechanical properties can be optimized through specific heat treatment processes.

- Formability: It can be processed into various shapes, including plates, sheets, and extrusions, to meet different manufacturing needs.

- Weldability: Like many high-strength aluminum alloys, 7055 has limited weldability; welding reduces its strength and alternative joining methods are generally preferred.

Processing and Forming Characteristics

| Processing Method | Description of Characteristics |

| Extrusion | Good, suitable for components with complex cross-sections |

| Heat Treatment | Crucial for enhancing strength (T7751 temper is highly representative) |

| Weldability | Poor, welding is not recommended; riveting or mechanical fastening is commonly used |

| Machinability | Good, suitable for high-precision manufacturing such as CNC machining |

7055 Aluminum Plate Manufacturing Standards and Certifications

- Standards: Complies with AMS 4206, ASTM B209, and MIL-HDBK-5 standards

- Certifications: AS9100 (Aerospace), ISO 9001, and NADCAP Quality Assurance

Comparison Between 7055 and 7075 Aluminum Alloys

Both 7055 and 7075 are high-strength aluminum alloys used in aerospace applications, but 7055 offers the following advantages:

- Higher Strength: 7055 offers greater tensile strength, especially after heat treatment.

- Better Corrosion Resistance: It has stronger resistance to stress corrosion cracking compared to 7075.

- Machinability: Suitable for CNC milling, drilling, and welding

- Weight Reduction: Reduces aircraft weight by 10–15%, improving fuel efficiency

Comparison with Other Aluminum Alloys (such as 7075)

| Property | 7055 Aluminum Alloy | 7075 Aluminum Alloy |

| Tensile Strength | Higher | High |

| Corrosion Resistance | Better | Moderate |

| Stress Corrosion Cracking Sensitivity | Lower | Slightly Higher |

| Cost | Slightly Higher | More Economical |

These advantages make 7055 the preferred choice for new aircraft designs that require exceptional performance.

Compared with general-purpose aluminum alloys such as 6061 and 5052, 7055 aluminum plate performs better in terms of strength, wear resistance, and fatigue resistance. However, its weldability is poor and requires special processing techniques.

Limitations of 7055 Aluminum

- Weldability: Requires special techniques to prevent cracking

- Cost: Higher than standard alloys due to complex processing methods

7055 aluminum plate is a cornerstone of modern aerospace engineering, offering unparalleled strength, light weight, and corrosion resistance. With advancements in manufacturing and strict industry standards, its applications have expanded to military and automotive fields.

You may also be interested in the following

-

7150 7055 2024 Aluminum for Aircraft Wing Panel

7150, 7055, 2024 have high strength, high toughness, corrosion resistance and other properties, suitable for manufacturing wing skin wall panels, wing ribs and webs and other structural parts.

-

7055 2024 Aluminum Plate for Aircraft Seats

7055 and 2024 aluminum alloy profiles are commonly used materials for manufacturing aircraft seats and are widely used due to their excellent performance.