7050 T7451 Aircraft Aluminum Plate Sheet

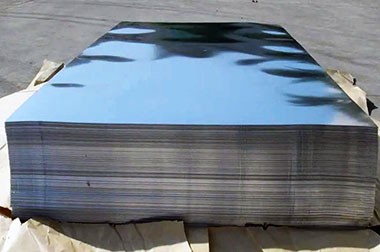

7050 aluminum alloy is a high-strength heat-treatable alloy belonging to the Al-Zn-Mg-Cu series of ultra-high-strength aluminum alloys, and it is a key structural material in the aerospace field. Its main alloying elements are zinc (Zn), magnesium (Mg), and copper (Cu), with a small amount of zirconium (Zr) added to replace the traditional chromium (Cr) element. This improvement significantly enhances the alloy's stress corrosion resistance and toughness.

7050 aluminum belongs to the 7000 series aluminum alloys and is similar to the 7075 alloy but offers some significant advantages. Compared to the older and more mature 7075 alloy, 7050 exhibits superior toughness and corrosion resistance. Due to its lower quench sensitivity than most other aerospace alloys, the alloy retains its strength characteristics even in thicker sections, while maintaining good stress corrosion cracking resistance and fracture toughness.

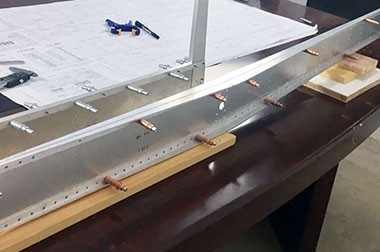

Because of its low quench sensitivity and ability to retain strength in thick sections, 7050 aluminum is especially suitable for thick plate applications (thickness from 3 inches to 6 inches). Therefore, 7050 aluminum alloy is a premium aerospace material for applications such as fuselage frames, bulkheads, and wing skins.

7050 aluminum alloy plates are available in two temper conditions. T7651 (AMS 4201) offers the highest strength, good exfoliation corrosion resistance, and average stress corrosion cracking resistance. T7451 (AMS 4050), on the other hand, has slightly lower strength but better stress corrosion cracking resistance and excellent exfoliation corrosion resistance.

7050 T7451 temper refers to artificial aging treatment to ensure material stability at high temperatures. Additionally, this aluminum plate offers good weldability and is widely used in wings, fuselage, and other critical components. Its excellent fatigue resistance and stress corrosion resistance make it perform well under harsh conditions.

The Specification of 7050 Aluminum Plate

Haomei Aluminum offers 7050 aluminum in various forms and specifications, including 7050 round bars in the T74511 (AMS 4342) condition.

- AMS 4050: 7050-T7451 Plate

- AMS 4107: 7050-T74 Die Forging

- AMS 4108: 7050-T7452 Hand Forgings

- AMS 4201: 7050-T7651 Plate

- AMS 4333: 7050-T7452 Forgings

- AMS 4340: 7050-T76511 Extrusions

- AMS 4341: 7050-T73511 Extrusions

- AMS 4342: 7050-T74511 Extrusions

- AMS 4342: 7050-T74511 Bars

7050 aerospace aluminum is available in a variety of forms and specifications to meet the needs of different applications.

7050 Aluminum Plate Specifications

- Thickness range: 0.250 to 8.000 inches (6 to 203 mm)

- Width and length: customizable according to customer requirements

- Standard widths are typically 48 inches (1219 mm) and 60 inches (1524 mm)

7050 Aluminum Bar Specifications

- Diameter range: 1.0 to 400 mm

- Length up to 6000 mm

- Usually supplied in T651 or T7451 temper

7050 Aluminum Forging Specifications

- Available in various complex shapes of die forgings and open-die forgings

- Thickness can exceed 6 inches (152 mm)

- Suitable for manufacturing high-strength aircraft structural parts

7050 Aluminum Tube Specifications

- Outer diameter range: 6 to 300 mm

- Wall thickness: 0.5 to 50 mm

- Available in seamless and welded tubes

Advantages of 7050 Aluminum Plate

- Strength and Toughness: 7050 aluminum alloy strikes a good balance between strength and toughness. Its strength is close to that of 7075 aluminum alloy, but it offers better toughness, especially in thicker sections. This makes 7050 more reliable in aerospace structures, particularly for critical parts like fuselage and wing skins, where it can withstand higher mechanical stresses.

- Corrosion Resistance and Anti-Exfoliation: Compared to 7075 aluminum alloy, 7050 offers stronger corrosion resistance. Particularly in terms of stress corrosion resistance, 7050 excels over 7075 and has better anti-exfoliation corrosion properties. Its resistance to stress corrosion cracking (SCC) is particularly notable in thick plates, making it suitable for long-term stable applications, such as aircraft fuselages and other parts exposed to harsh environments.

- Quench Sensitivity: 7050 aluminum alloy has lower quench sensitivity compared to 7075. This means that, even in thick plates, 7050 can maintain more uniform strength and other mechanical properties during production without being as prone to deformation during the quenching process as 7075.

- Suitable for Thick Plates: 7050 alloy is particularly suitable for aluminum plates with thicknesses between 3 to 6 inches (approximately 75 to 150 mm). This makes 7050 an ideal choice for manufacturing large-section structural components, especially in aircraft and spacecraft, where these thick plates are required to carry large loads.

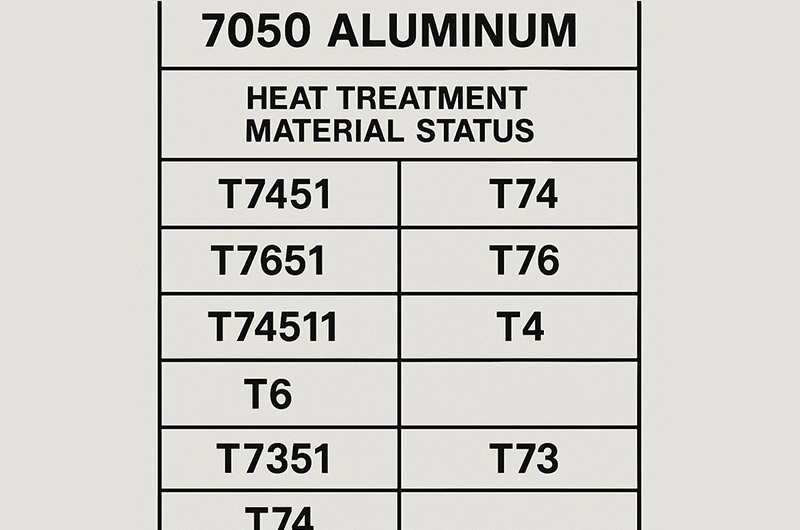

7050 Aluminum Temper and Heat Treatment

7050 aluminum alloy is typically supplied in various temper conditions, each corresponding to different heat treatment and processing methods to yield distinct mechanical properties.

7050 T7451 Temper

- Solution heat-treated, artificially aged, and stress-relieved by stretching

- Excellent resistance to stress corrosion cracking (SCC) and good exfoliation corrosion resistance

- Typical mechanical properties: tensile strength 524 MPa, yield strength 469 MPa, elongation 11%, shear strength 303 MPa

- Suitable for aerospace structural components requiring both high strength and corrosion resistance

7050 T7651 Temper

- Solution heat-treated, overaged, and stress-relieved by stretching

- Higher strength and good exfoliation corrosion resistance, but slightly lower SCC resistance than T7451

- Typical mechanical properties: tensile strength 552 MPa, yield strength 490 MPa, fatigue strength (5×10⁸ cycles) up to 71 MPa

- Suitable for applications requiring high strength and moderate SCC resistance

7050 T651 Temper

- Solution heat-treated, artificially aged, and stress-relieved by stretching

- Highest strength, but relatively lower stress corrosion resistance

- Typical mechanical properties: tensile strength approx. 572 MPa, yield strength approx. 503 MPa, hardness 150 HB, elongation 11%

- Suitable for applications requiring extremely high strength with less emphasis on corrosion resistance

7050 T73 Temper

- Solution heat-treated and triple overaged

- Good stress corrosion resistance but relatively lower strength

- Suitable for environments requiring particularly high corrosion resistance

Other specifications include ASTM B209, AMS 4340, and EN 3982, specially tailored for aerospace standards.

| Product Condition | Description |

| 7050-T7451 | 7050-T7451 aluminum alloy is a thick plate material subjected to solution heat treatment, quenching, mild stretching, and high-temperature artificial aging, possessing excellent resistance to stress corrosion cracking and good overall strength. This condition is especially suitable for aerospace environments with extremely high corrosion sensitivity, widely used in main load-bearing aircraft structures such as wing beams, landing gear beams, and fuselage connection structures. It maintains good performance under high strength demands and corrosive environments, ensuring aircraft structural safety and lifespan. |

| 7050-T7651 | 7050-T7651 aluminum alloy is produced by longer or higher temperature artificial aging treatment based on T7451, further enhancing the material's strength while still maintaining good resistance to stress corrosion cracking. This condition is mainly used for aerospace structural parts with high load and strength requirements. Typical applications include thick wing main beams and load-bearing frameworks, especially suitable for military and commercial aircraft structures with long service cycles and difficult maintenance, ensuring reliability and safety. |

| 7050-T74511 | 7050-T74511 aluminum alloy is a heat treatment condition for extruded profiles, involving solution heat treatment, quenching, mild stretching, and high-temperature artificial aging, offering excellent resistance to exfoliation corrosion and stress corrosion cracking. This condition is widely used in manufacturing high-strength extruded aircraft parts, such as stiffeners, frame profiles, and connectors. It is the preferred material for aerospace structural parts that require both corrosion resistance and high strength, ensuring stability and durability of structural components in complex service environments. |

| 7050-T6 | 7050-T6 aluminum alloy undergoes solution heat treatment and single-stage artificial aging, exhibiting extremely high tensile and yield strength, outperforming most other tempers in strength. However, this condition has relatively poor resistance to stress corrosion cracking and is not suitable for long-term exposure to corrosive environments. It is mainly used in non-load-bearing structural parts with extremely high strength requirements but controlled or acceptable corrosion environments, such as test structural samples or reinforcements in space-limited areas, meeting high strength demands but relatively low corrosion resistance needs. |

| 7050-T7351 | 7050-T7351 aluminum alloy uses a two-stage artificial aging process that significantly improves corrosion resistance, particularly showing excellent resistance to exfoliation corrosion and stress corrosion cracking in thick plate applications. This condition is widely used in aerospace main load-bearing structures, such as large box beams, webs, and skins, especially suitable for key structural parts of military and large civil aircraft, ensuring excellent corrosion resistance and structural strength during long-term service. |

| 7050-T74 | 7050-T74 aluminum alloy achieves a good balance between corrosion resistance and moderate strength through a special two-stage artificial aging process. This condition is commonly used in aircraft parts with relatively high long-term service reliability requirements but moderate structural load, such as medium-thickness skins and support components. 7050-T74 provides an excellent balance of service life and process performance, making it an ideal choice balancing material properties and cost-effectiveness, widely applied in non-primary load-bearing areas of aerospace structures. |

Characteristics of 7050 T7451 Aircraft Aluminum Plate Sheet

High Strength and Lightweight Characteristics

One of the most notable features of 7050 aerospace aluminum is its excellent combination of high strength and light weight. This alloy offers tensile strength up to 520–590 MPa, yield strength ranging from 455–490 MPa, and hardness (HB) up to 135, far surpassing ordinary aluminum alloys and even outperforming some mild steels. More importantly, the density of 7050 aluminum alloy is only 2.83 g/cm³, about one-third that of steel.

Excellent Corrosion Resistance

7050 aerospace aluminum achieves outstanding corrosion resistance, particularly against stress corrosion cracking (SCC) and exfoliation corrosion, through its specially designed alloy composition and heat treatment process. Compared to the conventional 7075 aluminum alloy, 7050 enhances SCC resistance significantly by increasing the Zn and Cu contents, adjusting the Cu/Mg ratio, and replacing chromium with zirconium.

Good Fracture Toughness and Fatigue Resistance

7050 aerospace aluminum exhibits good fracture toughness and fatigue resistance, which are critical for aerospace structural components. Its fracture toughness can reach 35–40 MPa√m, significantly higher than the 28–32 MPa√m range of the traditional 7075 aluminum alloy.

Good Machinability and Heat Treatment Response

7050 aerospace aluminum offers good machinability and heat treatment response, making it suitable for fabricating complex-shaped structural components through various processing methods. By precisely controlling solution temperature, time, and aging schedule, the desired strength-toughness combination can be achieved.

7050 T7451 Aircraft Aluminum Plate Sheet Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 7050 | 0.12 | 0.15 | 2.0-2.6 | 0.10 | 1.9-2.6 | 0.04 | 5.7-6.7 | 0.08-0.15 | 0.06 | GB/AMS/EN |

7050 T7451 Aircraft Aluminum Plate Sheet Mechanical Properties

| Material | Temper | Thickness | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation in 2" % |

| Alloy 7050 Plate (longitudinal) | T7451 | <2.0 | 74 | 64 | 10 |

| Alloy 7050 Plate (longitudinal) | T7451 | 2.0 -3.0 | 73 | 63 | 9 |

| Alloy 7050 Plate (longitudinal) | T7451 | 3.0 - 4.0 | 72 | 62 | 9 |

| Alloy 7050 Plate (longitudinal) | T7451 | 4.0 - 5.0 | 71 | 61 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 0.25 - 1.0 | 76 | 66 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 1.0 - 1.5 | 77 | 67 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 1.5 - 2.0 | 76 | 66 | 9 |

| Alloy 7050 Plate (longitudinal) | T7651 | 2.0 - 3.0 | 76 | 66 | 8 |

7050 Aluminum Plate Physical Properties

| Property | Value |

| Density | 2.83 g/cm³ (0.102 lb/in³) |

| Annealing Temperature | 415°C (775°F) |

| Solution Heat Treatment Temperature | 475°C (890°F) |

| Aging Temperature | 120-175°C (250-350°F) |

Advantages of 7050 Aerospace Aluminum Compared with Other Aerospace Alloys

Comparison of 7050 and 7075 Aluminum Alloys

| Property | 7050-T7451 | 7075-T6 | Advantage Description |

| Tensile Strength (MPa) | 524 | 572 | Slightly lower, but corrosion resistance significantly improved |

| Stress Corrosion Resistance | Excellent | Average | 7050 far superior to 7075 |

| Fracture Toughness (MPa√m) | 35–40 | 28–32 | 7050 is about 25% higher than 7075 |

| Fatigue Strength (10⁷ cycles) (MPa) | 240 | 178 | 7050 is about 35% higher than 7075 |

| Anisotropy Ratio | ≤1.05 | 1.15 | 7050 offers more uniform properties |

Comparison Advantages Between 7050 and 2024 Aluminum Alloys

- Higher Strength: The tensile strength of 7050 aluminum alloy can reach 520–590 MPa, while 2024-T351 has a tensile strength of about 470 MPa.

- Better Corrosion Resistance: 7050 aluminum alloy shows significantly better resistance to stress corrosion and exfoliation corrosion compared to 2024 aluminum alloy.

- Lower Density: The density of 7050 aluminum alloy is approximately 2.83 g/cm³, slightly lower than the 2.78 g/cm³ of 2024 aluminum alloy.

- Better Low-Temperature Performance: 7050 aluminum alloy maintains its mechanical properties better than 2024 alloy in low-temperature environments.

Comparison Advantages Between 7050 and New Aluminum-Lithium Alloys

- Higher Strength: The strength of currently available commercial aluminum-lithium alloys is generally lower than that of 7050 aluminum alloy.

- Better Fracture Toughness: 7050 aluminum alloy offers better fracture toughness than most aluminum-lithium alloys.

- More Mature Application Experience: 7050 aluminum alloy has been used for many years in the aerospace industry.

- Lower Cost: Compared to aluminum-lithium alloys, 7050 aluminum alloy has lower production and processing costs.

7050 Aluminum Plate Core Performance Features

Corrosion Resistance

Outstanding resistance to stress corrosion cracking (SCC) and exfoliation corrosion, superior to most 7xxx series aluminum alloys.

Environmental Adaptability

Fatigue resistance, damage tolerance, suitable for high stress cyclic load scenarios.

Electrical conductivity of 41% IACS, density 2.83g/cm³, combining lightweight and conductivity.

Applications of 7050 Aluminum Plate in the Aerospace Field

Aircraft Structural Applications

Wing Structure

Wing Spars: 7050-T7451 and T7651 thick plates Wing Skins: 7050-T7451 thin plates Ribs and Stringers: 7050 aluminum alloy extrusions and forgings

- Wing Spars: 7050-T7451 and T7651 thick plates are used to manufacture the main load-bearing spars of the wings, providing high strength and lightweight structural support.

- Wing Skins: 7050-T7451 thin plates are used to manufacture the upper and lower wing skins, bearing aerodynamic loads and structural stress during flight.

- Ribs and Stringers: 7050 aluminum alloy extrusions and forgings are used to manufacture ribs and stringers, enhancing the structural stability of the wings.

Fuselage Structure

- Fuselage Frames: 7050-T7451 and T7651 thick plates and forgings

- Fuselage Skins: 7050-T7451 thin plates

- Bulkheads and Floor Beams: 7050 aluminum alloy forgings and extrusions

- Fuselage Frames: 7050-T7451 and T7651 thick plates and forgings are used to manufacture the fuselage ring frames, bearing bending and shear loads of the fuselage.

- Fuselage Skins: 7050-T7451 thin plates are used for fuselage skins, providing aerodynamic shape and structural support.

- Bulkheads and Floor Beams: 7050 aluminum alloy forgings and extrusions are used for bulkheads and floor beams, enhancing structural strength and stability of the fuselage.

Empennage Structure

- Horizontal and Vertical Stabilizers: 7050 aluminum alloy thick plates and forgings

- Tail Beams and Ribs: 7050 aluminum alloy extrusions and forgings

- Horizontal and Vertical Stabilizers: 7050 aluminum alloy thick plates and forgings are used to manufacture structural components of the horizontal and vertical stabilizers, bearing aerodynamic and vibrational loads during flight.

- Tail Beams and Ribs: 7050 aluminum alloy extrusions and forgings are used to manufacture the beams and ribs of the tail, providing structural support and stability.

Landing Gear System Applications

- Landing Gear Struts: 7050-T7451 and T7651 forgings

- Landing Gear Beams and Struts: 7050 aluminum alloy forgings and extrusions

- Landing Gear Doors: 7050-T7451 thin plates

- Landing Gear Actuation Cylinders: 7050 aluminum alloy tubes and forgings

- Landing Gear Struts: 7050-T7451 and T7651 forgings are used to manufacture landing gear struts, bearing huge impact and vibrational loads during takeoff and landing.

- Landing Gear Beams and Struts: 7050 aluminum alloy forgings and extrusions are used to manufacture landing gear beams and struts, providing structural support and stability.

- Landing Gear Doors: 7050-T7451 thin plates are used to manufacture landing gear doors, offering a lightweight and high-strength structural solution.

Spacecraft Applications

- Rocket Fuel Tanks: 7050 aluminum alloy is used to manufacture rocket fuel tanks, maintaining good mechanical properties even in low temperatures (-253°C).

- Rocket Shells and Frames: 7050 aluminum alloy thick plates and forgings

- Satellite Structural Frames: 7050 aluminum alloy is used to manufacture structural frames for satellites, providing lightweight and high-strength support structures.

7050 Aluminum Plate Manufacturing and Processing

Although 7050 aluminum has limited cold workability, its good machinability makes it suitable for manufacturing precision components. However, welding is generally not recommended as it may reduce the strength and corrosion resistance in the weld zone.

7050 Aluminum Processing and Welding

Although 7050 aluminum alloy has high strength, its machinability remains good compared to other high-strength alloys. After heat treatment, it retains excellent mechanical properties and can accommodate various manufacturing processes. However, due to its high strength, the weldability of 7050 aluminum alloy is poor and requires appropriate welding methods, such as using special aluminum welding alloys or suitable preheating and post-treatment processes, to ensure the quality of the welded joints.

7050 aluminum plate is a critical material in the aerospace industry, performing excellently in applications requiring high strength, superior corrosion resistance, low quenching sensitivity, and outstanding toughness. Its comprehensive performance makes it a more reliable choice than traditional high-strength aluminum alloys like 7075, especially in thicker material applications. 7050 can maintain more stable properties and reduce potential risks caused by stress corrosion. Therefore, 7050 aluminum plate is an ideal material for manufacturing aircraft, spacecraft, and other high-end aerospace components.

Manufacturing Considerations

- Welding: Welding is not recommended due to the presence of porosity and low weld strength. Gas Tungsten Arc Welding (GTAW) is not advised.

- Heat Treatment: Aging treatment needs to be performed at 122-163°C (250-325°F) to improve strength through precipitation hardening.

- Formability: The best forming condition is full annealing (softened state), but cold workability is limited.

7050 Aluminum Plate Industry Standards

Standards: AMS 4050 (T7451), AMS 4201 (T7651), and ASTM B209 are widely used.

7050 aluminum plate is a cornerstone of the aerospace and defense industries, offering unmatched strength, corrosion resistance, and durability. Its unique tempering characteristics and adaptability to thick cross-sections give it an irreplaceable advantage in high-stress applications, but due to welding limitations and precise heat treatment requirements, careful handling is necessary.

7050 aluminum plate is a premium aerospace alloy that combines high strength, excellent corrosion resistance, and good toughness, especially in thick-walled components. Its properties make it an ideal choice for critical structural parts in harsh environments.

Stock of Haomei 7050 aerospace aluminum plate sheet

| Item | Temper | Thinckness(in) | Width(in) | Length(in) |

| 7050 Aluminum Plate 0.25" x 12" x 24" | T7451/T7351/T651 | 0.25" | 12" | 24" |

| 7050 Aluminum Plate 0.25" x 12" x 36" | T7451/T7351/T651 | 0.25" | 12" | 36" |

| 7050 Aluminum Plate 0.25" x 12" x 48" | T7451/T7351/T651 | 0.25" | 12" | 48" |

| 7050 Aluminum Plate 0.25" x 24" x 48" | T7451/T7351/T651 | 0.25" | 24" | 48" |

| 7050 Aluminum Plate 0.25" x 24" x 144" | T7451/T7351/T651 | 0.25" | 24" | 144" |

| 7050 Aluminum Plate 0.25" x 24" x 144.5" | T7451/T7351/T651 | 0.25" | 24" | 144.5" |

| 7050 Aluminum Plate 0.25" x 36" x 144" | T7451/T7351/T651 | 0.25" | 36" | 144" |

| 7050 Aluminum Plate 0.25" x 36" x 144.5" | T7451/T7351/T651 | 0.25" | 36" | 144.5" |

| 7050 Aluminum Plate 0.25" x 48" x 144" | T7451/T7351/T651 | 0.25" | 48" | 144" |

| 7050 Aluminum Plate 0.25" x 48" x 144.5" | T7451/T7351/T651 | 0.25" | 48" | 144.5" |

| 7050 Aluminum Plate 0.25" x 48.5" x 144" | T7451/T7351/T651 | 0.25" | 48.5" | 144" |

| 7050 Aluminum Plate 0.25" x 48.5" x 144.5" | T7451/T7351/T651 | 0.25" | 48.5" | 144.5" |

| 7050 Aluminum Plate 0.25" x 60" x 144" | T7451/T7351/T651 | 0.25" | 60" | 144" |

| 7050 Aluminum Plate 0.25" x 60" x 144.5" | T7451/T7351/T651 | 0.25" | 60" | 144.5" |

| 7050 Aluminum Plate 0.50" x 12" x 24" | T7451/T7351/T651 | 0.50" | 12" | 24" |

| 7050 Aluminum Plate 0.50" x 12" x 36" | T7451/T7351/T651 | 0.50" | 12" | 36" |

| 7050 Aluminum Plate 0.50" x 12" x 48" | T7451/T7351/T651 | 0.50" | 12" | 48" |

| 7050 Aluminum Plate 0.50" x 24" x 48" | T7451/T7351/T651 | 0.50" | 24" | 48" |

| 7050 Aluminum Plate 0.50" x 24" x 144" | T7451/T7351/T651 | 0.50" | 24" | 144" |

| 7050 Aluminum Plate 0.50" x 24" x 144.5" | T7451/T7351/T651 | 0.50" | 24" | 144.5" |

| 7050 Aluminum Plate 0.50" x 36" x 144" | T7451/T7351/T651 | 0.50" | 36" | 144" |

| 7050 Aluminum Plate 0.50" x 36" x 144.5" | T7451/T7351/T651 | 0.50" | 36" | 144.5" |

| 7050 Aluminum Plate 0.50" x 48" x 144" | T7451/T7351/T651 | 0.50" | 48" | 144" |

| 7050 Aluminum Plate 0.50" x 48" x 144.5" | T7451/T7351/T651 | 0.50" | 48" | 144.5" |

| 7050 Aluminum Plate 0.50" x 48.5" x 144" | T7451/T7351/T651 | 0.50" | 48.5" | 144" |

| 7050 Aluminum Plate 0.50" x 48.5" x 144.5" | T7451/T7351/T651 | 0.50" | 48.5" | 144.5" |

| 7050 Aluminum Plate 0.50" x 60" x 144" | T7451/T7351/T651 | 0.50" | 60" | 144" |

| 7050 Aluminum Plate 0.50" x 60" x 144.5" | T7451/T7351/T651 | 0.50" | 60" | 144.5" |

| 7050 Aluminum Plate 1.00" x 12" x 24" | T7451/T7351/T651 | 1.00" | 12" | 24" |

| 7050 Aluminum Plate 1.00" x 12" x 36" | T7451/T7351/T651 | 1.00" | 12" | 36" |

| 7050 Aluminum Plate 1.00" x 12" x 48" | T7451/T7351/T651 | 1.00" | 12" | 48" |

| 7050 Aluminum Plate 1.00" x 24" x 48" | T7451/T7351/T651 | 1.00" | 24" | 48" |

| 7050 Aluminum Plate 1.00" x 24" x 144" | T7451/T7351/T651 | 1.00" | 24" | 144" |

| 7050 Aluminum Plate 1.00" x 24" x 144.5" | T7451/T7351/T651 | 1.00" | 24" | 144.5" |

| 7050 Aluminum Plate 1.00" x 36" x 144" | T7451/T7351/T651 | 1.00" | 36" | 144" |

| 7050 Aluminum Plate 1.00" x 36" x 144.5" | T7451/T7351/T651 | 1.00" | 36" | 144.5" |

| 7050 Aluminum Plate 1.00" x 48" x 144" | T7451/T7351/T651 | 1.00" | 48" | 144" |

| 7050 Aluminum Plate 1.00" x 48" x 144.5" | T7451/T7351/T651 | 1.00" | 48" | 144.5" |

| 7050 Aluminum Plate 1.00" x 48.5" x 144" | T7451/T7351/T651 | 1.00" | 48.5" | 144" |

| 7050 Aluminum Plate 1.00" x 48.5" x 144.5" | T7451/T7351/T651 | 1.00" | 48.5" | 144.5" |

| 7050 Aluminum Plate 1.00" x 60" x 144" | T7451/T7351/T651 | 1.00" | 60" | 144" |

| 7050 Aluminum Plate 1.00" x 60" x 144.5" | T7451/T7351/T651 | 1.00" | 60" | 144.5" |

| 7050 Aluminum Plate 1.25" x 12" x 24" | T7451/T7351/T651 | 1.25" | 12" | 24" |

| 7050 Aluminum Plate 1.25" x 12" x 36" | T7451/T7351/T651 | 1.25" | 12" | 36" |

| 7050 Aluminum Plate 1.25" x 12" x 48" | T7451/T7351/T651 | 1.25" | 12" | 48" |

| 7050 Aluminum Plate 1.25" x 24" x 48" | T7451/T7351/T651 | 1.25" | 24" | 48" |

| 7050 Aluminum Plate 1.25" x 24" x 144" | T7451/T7351/T651 | 1.25" | 24" | 144" |

| 7050 Aluminum Plate 1.25" x 24" x 144.5" | T7451/T7351/T651 | 1.25" | 24" | 144.5" |

| 7050 Aluminum Plate 1.25" x 36" x 144" | T7451/T7351/T651 | 1.25" | 36" | 144" |

| 7050 Aluminum Plate 1.25" x 36" x 144.5" | T7451/T7351/T651 | 1.25" | 36" | 144.5" |

| 7050 Aluminum Plate 1.25" x 48" x 144" | T7451/T7351/T651 | 1.25" | 48" | 144" |

| 7050 Aluminum Plate 1.25" x 48" x 144.5" | T7451/T7351/T651 | 1.25" | 48" | 144.5" |

| 7050 Aluminum Plate 1.25" x 48.5" x 144" | T7451/T7351/T651 | 1.25" | 48.5" | 144" |

| 7050 Aluminum Plate 1.25" x 48.5" x 144.5" | T7451/T7351/T651 | 1.25" | 48.5" | 144.5" |

| 7050 Aluminum Plate 1.25" x 60" x 144" | T7451/T7351/T651 | 1.25" | 60" | 144" |

| 7050 Aluminum Plate 1.25" x 60" x 144.5" | T7451/T7351/T651 | 1.25" | 60" | 144.5" |

| 7050 Aluminum Plate 1.75" x 12" x 24" | T7451/T7351/T651 | 1.75" | 12" | 24" |

| 7050 Aluminum Plate 1.75" x 12" x 36" | T7451/T7351/T651 | 1.75" | 12" | 36" |

| 7050 Aluminum Plate 1.75" x 12" x 48" | T7451/T7351/T651 | 1.75" | 12" | 48" |

| 7050 Aluminum Plate 1.75" x 24" x 48" | T7451/T7351/T651 | 1.75" | 24" | 48" |

| 7050 Aluminum Plate 1.75" x 24" x 144" | T7451/T7351/T651 | 1.75" | 24" | 144" |

| 7050 Aluminum Plate 1.75" x 24" x 144.5" | T7451/T7351/T651 | 1.75" | 24" | 144.5" |

| 7050 Aluminum Plate 1.75" x 36" x 144" | T7451/T7351/T651 | 1.75" | 36" | 144" |

| 7050 Aluminum Plate 1.75" x 36" x 144.5" | T7451/T7351/T651 | 1.75" | 36" | 144.5" |

| 7050 Aluminum Plate 1.75" x 48" x 144" | T7451/T7351/T651 | 1.75" | 48" | 144" |

| 7050 Aluminum Plate 1.75" x 48" x 144.5" | T7451/T7351/T651 | 1.75" | 48" | 144.5" |

| 7050 Aluminum Plate 1.75" x 48.5" x 144" | T7451/T7351/T651 | 1.75" | 48.5" | 144" |

| 7050 Aluminum Plate 1.75" x 48.5" x 144.5" | T7451/T7351/T651 | 1.75" | 48.5" | 144.5" |

| 7050 Aluminum Plate 1.75" x 60" x 144" | T7451/T7351/T651 | 1.75" | 60" | 144" |

| 7050 Aluminum Plate 1.75" x 60" x 144.5" | T7451/T7351/T651 | 1.75" | 60" | 144.5" |

| 7050 Aluminum Plate 2.00" x 12" x 24" | T7451/T7351/T651 | 2.00" | 12" | 24" |

| 7050 Aluminum Plate 2.00" x 12" x 36" | T7451/T7351/T651 | 2.00" | 12" | 36" |

| 7050 Aluminum Plate 2.00" x 12" x 48" | T7451/T7351/T651 | 2.00" | 12" | 48" |

| 7050 Aluminum Plate 2.00" x 24" x 48" | T7451/T7351/T651 | 2.00" | 24" | 48" |

| 7050 Aluminum Plate 2.00" x 24" x 144" | T7451/T7351/T651 | 2.00" | 24" | 144" |

| 7050 Aluminum Plate 2.00" x 24" x 144.5" | T7451/T7351/T651 | 2.00" | 24" | 144.5" |

| 7050 Aluminum Plate 2.00" x 36" x 144" | T7451/T7351/T651 | 2.00" | 36" | 144" |

| 7050 Aluminum Plate 2.00" x 36" x 144.5" | T7451/T7351/T651 | 2.00" | 36" | 144.5" |

| 7050 Aluminum Plate 2.00" x 48" x 144" | T7451/T7351/T651 | 2.00" | 48" | 144" |

| 7050 Aluminum Plate 2.00" x 48" x 144.5" | T7451/T7351/T651 | 2.00" | 48" | 144.5" |

| 7050 Aluminum Plate 2.00" x 48.5" x 144" | T7451/T7351/T651 | 2.00" | 48.5" | 144" |

| 7050 Aluminum Plate 2.00" x 48.5" x 144.5" | T7451/T7351/T651 | 2.00" | 48.5" | 144.5" |

| 7050 Aluminum Plate 2.00" x 60" x 144" | T7451/T7351/T651 | 2.00" | 60" | 144" |

| 7050 Aluminum Plate 2.00" x 60" x 144.5" | T7451/T7351/T651 | 2.00" | 60" | 144.5" |

| 7050 Aluminum Plate 2.50" x 12" x 24" | T7451/T7351/T651 | 2.50" | 12" | 24" |

| 7050 Aluminum Plate 2.50" x 12" x 36" | T7451/T7351/T651 | 2.50" | 12" | 36" |

| 7050 Aluminum Plate 2.50" x 12" x 48" | T7451/T7351/T651 | 2.50" | 12" | 48" |

| 7050 Aluminum Plate 2.50" x 24" x 48" | T7451/T7351/T651 | 2.50" | 24" | 48" |

| 7050 Aluminum Plate 2.50" x 24" x 144" | T7451/T7351/T651 | 2.50" | 24" | 144" |

| 7050 Aluminum Plate 2.50" x 24" x 144.5" | T7451/T7351/T651 | 2.50" | 24" | 144.5" |

| 7050 Aluminum Plate 2.50" x 36" x 144" | T7451/T7351/T651 | 2.50" | 36" | 144" |

| 7050 Aluminum Plate 2.50" x 36" x 144.5" | T7451/T7351/T651 | 2.50" | 36" | 144.5" |

| 7050 Aluminum Plate 2.50" x 48" x 144" | T7451/T7351/T651 | 2.50" | 48" | 144" |

| 7050 Aluminum Plate 2.50" x 48" x 144.5" | T7451/T7351/T651 | 2.50" | 48" | 144.5" |

| 7050 Aluminum Plate 2.50" x 48.5" x 144" | T7451/T7351/T651 | 2.50" | 48.5" | 144" |

| 7050 Aluminum Plate 2.50" x 48.5" x 144.5" | T7451/T7351/T651 | 2.50" | 48.5" | 144.5" |

| 7050 Aluminum Plate 2.50" x 60" x 144" | T7451/T7351/T651 | 2.50" | 60" | 144" |

| 7050 Aluminum Plate 2.50" x 60" x 144.5" | T7451/T7351/T651 | 2.50" | 60" | 144.5" |

| 7050 Aluminum Plate 2.75" x 12" x 24" | T7451/T7351/T651 | 2.75" | 12" | 24" |

| 7050 Aluminum Plate 2.75" x 12" x 36" | T7451/T7351/T651 | 2.75" | 12" | 36" |

| 7050 Aluminum Plate 2.75" x 12" x 48" | T7451/T7351/T651 | 2.75" | 12" | 48" |

| 7050 Aluminum Plate 2.75" x 24" x 48" | T7451/T7351/T651 | 2.75" | 24" | 48" |

| 7050 Aluminum Plate 2.75" x 24" x 144" | T7451/T7351/T651 | 2.75" | 24" | 144" |

| 7050 Aluminum Plate 2.75" x 24" x 144.5" | T7451/T7351/T651 | 2.75" | 24" | 144.5" |

| 7050 Aluminum Plate 2.75" x 36" x 144" | T7451/T7351/T651 | 2.75" | 36" | 144" |

| 7050 Aluminum Plate 2.75" x 36" x 144.5" | T7451/T7351/T651 | 2.75" | 36" | 144.5" |

| 7050 Aluminum Plate 2.75" x 48" x 144" | T7451/T7351/T651 | 2.75" | 48" | 144" |

| 7050 Aluminum Plate 2.75" x 48" x 144.5" | T7451/T7351/T651 | 2.75" | 48" | 144.5" |

| 7050 Aluminum Plate 2.75" x 48.5" x 144" | T7451/T7351/T651 | 2.75" | 48.5" | 144" |

| 7050 Aluminum Plate 2.75" x 48.5" x 144.5" | T7451/T7351/T651 | 2.75" | 48.5" | 144.5" |

| 7050 Aluminum Plate 2.75" x 60" x 144" | T7451/T7351/T651 | 2.75" | 60" | 144" |

| 7050 Aluminum Plate 2.75" x 60" x 144.5" | T7451/T7351/T651 | 2.75" | 60" | 144.5" |

| 7050 Aluminum Plate 3.00" x 12" x 24" | T7451/T7351/T651 | 3.00" | 12" | 24" |

| 7050 Aluminum Plate 3.00" x 12" x 36" | T7451/T7351/T651 | 3.00" | 12" | 36" |

| 7050 Aluminum Plate 3.00" x 12" x 48" | T7451/T7351/T651 | 3.00" | 12" | 48" |

| 7050 Aluminum Plate 3.00" x 24" x 48" | T7451/T7351/T651 | 3.00" | 24" | 48" |

| 7050 Aluminum Plate 3.00" x 24" x 144" | T7451/T7351/T651 | 3.00" | 24" | 144" |

| 7050 Aluminum Plate 3.00" x 24" x 144.5" | T7451/T7351/T651 | 3.00" | 24" | 144.5" |

| 7050 Aluminum Plate 3.00" x 36" x 144" | T7451/T7351/T651 | 3.00" | 36" | 144" |

| 7050 Aluminum Plate 3.00" x 36" x 144.5" | T7451/T7351/T651 | 3.00" | 36" | 144.5" |

| 7050 Aluminum Plate 3.00" x 48" x 144" | T7451/T7351/T651 | 3.00" | 48" | 144" |

| 7050 Aluminum Plate 3.00" x 48" x 144.5" | T7451/T7351/T651 | 3.00" | 48" | 144.5" |

| 7050 Aluminum Plate 3.00" x 48.5" x 144" | T7451/T7351/T651 | 3.00" | 48.5" | 144" |

| 7050 Aluminum Plate 3.00" x 48.5" x 144.5" | T7451/T7351/T651 | 3.00" | 48.5" | 144.5" |

| 7050 Aluminum Plate 3.00" x 60" x 144" | T7451/T7351/T651 | 3.00" | 60" | 144" |

| 7050 Aluminum Plate 3.00" x 60" x 144.5" | T7451/T7351/T651 | 3.00" | 60" | 144.5" |

| 7050 Aluminum Plate 3.25" x 12" x 24" | T7451/T7351/T651 | 3.25" | 12" | 24" |

| 7050 Aluminum Plate 3.25" x 12" x 36" | T7451/T7351/T651 | 3.25" | 12" | 36" |

| 7050 Aluminum Plate 3.25" x 12" x 48" | T7451/T7351/T651 | 3.25" | 12" | 48" |

| 7050 Aluminum Plate 3.25" x 24" x 48" | T7451/T7351/T651 | 3.25" | 24" | 48" |

| 7050 Aluminum Plate 3.25" x 24" x 144" | T7451/T7351/T651 | 3.25" | 24" | 144" |

| 7050 Aluminum Plate 3.25" x 24" x 144.5" | T7451/T7351/T651 | 3.25" | 24" | 144.5" |

| 7050 Aluminum Plate 3.25" x 36" x 144" | T7451/T7351/T651 | 3.25" | 36" | 144" |

| 7050 Aluminum Plate 3.25" x 36" x 144.5" | T7451/T7351/T651 | 3.25" | 36" | 144.5" |

| 7050 Aluminum Plate 3.25" x 48" x 144" | T7451/T7351/T651 | 3.25" | 48" | 144" |

| 7050 Aluminum Plate 3.25" x 48" x 144.5" | T7451/T7351/T651 | 3.25" | 48" | 144.5" |

| 7050 Aluminum Plate 3.25" x 48.5" x 144" | T7451/T7351/T651 | 3.25" | 48.5" | 144" |

| 7050 Aluminum Plate 3.25" x 48.5" x 144.5" | T7451/T7351/T651 | 3.25" | 48.5" | 144.5" |

| 7050 Aluminum Plate 3.25" x 60" x 144" | T7451/T7351/T651 | 3.25" | 60" | 144" |

| 7050 Aluminum Plate 3.25" x 60" x 144.5" | T7451/T7351/T651 | 3.25" | 60" | 144.5" |

| 7050 Aluminum Plate 3.75" x 12" x 24" | T7451/T7351/T651 | 3.75" | 12" | 24" |

| 7050 Aluminum Plate 3.75" x 12" x 36" | T7451/T7351/T651 | 3.75" | 12" | 36" |

| 7050 Aluminum Plate 3.75" x 12" x 48" | T7451/T7351/T651 | 3.75" | 12" | 48" |

| 7050 Aluminum Plate 3.75" x 24" x 48" | T7451/T7351/T651 | 3.75" | 24" | 48" |

| 7050 Aluminum Plate 3.75" x 24" x 144" | T7451/T7351/T651 | 3.75" | 24" | 144" |

| 7050 Aluminum Plate 3.75" x 24" x 144.5" | T7451/T7351/T651 | 3.75" | 24" | 144.5" |

| 7050 Aluminum Plate 3.75" x 36" x 144" | T7451/T7351/T651 | 3.75" | 36" | 144" |

| 7050 Aluminum Plate 3.75" x 36" x 144.5" | T7451/T7351/T651 | 3.75" | 36" | 144.5" |

| 7050 Aluminum Plate 3.75" x 48" x 144" | T7451/T7351/T651 | 3.75" | 48" | 144" |

| 7050 Aluminum Plate 3.75" x 48" x 144.5" | T7451/T7351/T651 | 3.75" | 48" | 144.5" |

| 7050 Aluminum Plate 3.75" x 48.5" x 144" | T7451/T7351/T651 | 3.75" | 48.5" | 144" |

| 7050 Aluminum Plate 3.75" x 48.5" x 144.5" | T7451/T7351/T651 | 3.75" | 48.5" | 144.5" |

| 7050 Aluminum Plate 3.75" x 60" x 144" | T7451/T7351/T651 | 3.75" | 60" | 144" |

| 7050 Aluminum Plate 3.75" x 60" x 144.5" | T7451/T7351/T651 | 3.75" | 60" | 144.5" |

Stress Corrosion Cracking Issues of 7050 Aluminum

Although 7050 aerospace aluminum has good resistance to stress corrosion, it may still experience stress corrosion cracking (SCC) under specific conditions. Protective measures include:

- Select appropriate heat treatment tempers based on service environments, such as prioritizing the T7451 temper in marine environments.

- Use surface treatment methods such as anodizing, Alodine coating, or laser cladding.

- Reduce residual stress in parts through proper structural design and manufacturing processes.

- Control the service environment to avoid exposure to highly corrosive conditions.

Non-Aerospace Applications of 7050 Aluminum Plate

Automotive Industry

- Body Frame: Tesla Model S uses 7xxx series alloys (including 7050)

- Chassis Components: BMW i3 chassis parts use 7xxx series alloys

- Crash Beams and Shock Towers: 7050 aluminum alloy is used to manufacture crash beams and shock towers in vehicles

- Wheels: 7050 aluminum alloy forged wheels, strength up to 600 MPa

Shipbuilding and Marine Engineering

- Hull Structures: 7050 aluminum alloy is used to manufacture hull components such as shells, decks, and bulkheads

- Superstructures: 7050 aluminum alloy is used to build ship superstructures

- Equipment Mounts: 7050 aluminum alloy forgings and machined parts

- Offshore Platform Structures: 7050 aluminum alloy is used for structural components of offshore platforms

High-Speed Trains and Rail Transit

- Train Body: 7050 aluminum alloy is used to build the body structure of high-speed trains

- Roof and Floor Structures: 7050 aluminum alloy extrusions and plates

- Window and Door Frames: 7050 aluminum alloy extrusions

- Interior Structural Parts: 7050 aluminum alloy thin plates and extrusions

Military and Defense

- Armor Plates: 7050 aluminum alloy armor plates are used for lightweight armored vehicle protection systems

- Vehicle Structures: 7050 aluminum alloy is used to manufacture structural components of armored vehicles

- Turrets and Weapon Mounts: 7050 aluminum alloy forgings

- Missile Launchers: 7050 aluminum alloy is used to manufacture missile launch systems

Other Applications

- Mold Making: Blow molds, ultrasonic welding molds, golf club head molds, etc.

- Mechanical Equipment: High-stress components, tooling fixtures, high-speed rotating parts

- Sports Equipment: Bicycle frames, golf clubs, etc.

- Consumer Electronics: Smartphone, tablet, and laptop casings

- Drone Structures: 7050 aerospace aluminum is known as the "dedicated aluminum for drones"

What is the difference between 6061 and 7050 aluminum?

In the aerospace field, 6061 aluminum alloy is commonly used for manufacturing aircraft fuselage structures, brackets, and components due to its good machinability and weldability.

- 7050 aluminum alloy is primarily used for high-strength structural applications in aerospace, such as aircraft wings, fuselages, and other load-bearing components, because of its high strength and good fatigue performance.

- Strength: 7050 aluminum alloy has a higher strength than 6061 aluminum alloy, making it suitable for components that bear greater loads.

- Weldability: 6061 aluminum alloy is easier to weld, while 7050 aluminum alloy has poorer welding performance.

- Application Fields: 6061 is suitable for structures with medium strength and corrosion resistance requirements, while 7050 is suitable for critical structures that require high strength and high fatigue performance.

You may also be interested in the following

-

7050 T7451 Aluminum for Aircraft Fuselage Reinforcement Frame

7050 T7451 high-strength aluminum alloy is particularly suitable for aircraft fuselage reinforcement frames, longitudinal beams, bulkheads and other structural parts.

-

7050 Aircraft Aluminum for Trailing Edge Ribs

7050 aluminum alloy is selected for the trailing edge ribs due to its strength-to-weight ratio, which helps maintain the optimal aerodynamic performance of the wing.

-

7050 Aircraft Aluminum for Cargo Floor Beams

7050 heavy-duty aluminum is designed for cargo hold floor beams, providing the strength necessary to support heavy loads while maintaining lightweight characteristics.

-

7050 Aircraft Aluminum for Bulkheads

7050 aerospace aluminum is used for bulkhead structures, providing strong structural support and compartments within the aircraft.

-

7050 Aerospace Aluminum for Baggage Bin Structure

7050 is a lightweight yet strong aluminum material used for suitcase structures, providing strength without adding unnecessary weight.

-

7050 7475 Aerospace Aluminum for Wing Attach Structure

Alloys 7050 and 7475 are used in the construction of wing attach structures, ensuring safety and durability during flight.

-

7050 7475 7099 Aircraft Aluminum for Wing Ribs

7050, 7475, and 7099 high-strength aluminum alloys are used to manufacture wing ribs, providing structural support to the wings and enhancing structural integrity.

-

7050 7475 7099 Aerospace Aluminum for Wing Spars

7050, 7475, and 7099 have outstanding strength-to-weight ratios and fatigue resistance, making these high-strength aluminum alloys ideal materials for manufacturing wing spars.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.

-

7050 Aircraft Aluminum for Leading Edge Ribs

Aluminum 7050 is specifically used for manufacturing leading edge ribs due to its strength and resistance to stress concentration, ensuring aerodynamic performance and structural support.