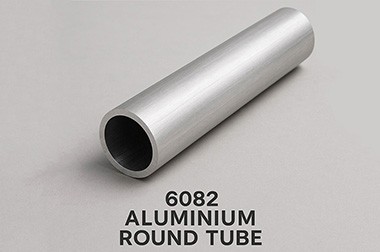

6082 T6 Aluminium Tube

6082-T6 is a high-strength aluminum alloy tube widely used in structural and aerospace fields due to its excellent mechanical properties and corrosion resistance.

- Alloy Series: Part of the 6000 series (Al-Mg-Si alloys), known for heat treatability and medium-to-high strength

- Temper Designation: The "T6" indicates solution heat treatment followed by artificial aging, enhancing tensile strength and hardness

6082 T6 aluminum tube is a tubular profile made from 6082 aluminum alloy through T6 heat treatment process (solution treatment + full artificial aging).

6082 T6 aluminum tube is a high-strength heat-treated forged alloy in the 6000 series, featuring excellent corrosion resistance, good machinability, and weldability. This alloy is widely used in structural and high-stress applications, including trusses, bridges, cranes, transport frames, and aerospace piping. It is primarily produced through extrusion or drawing processes and complies with international standards such as EN 755-2 and EN 754-2.

6082 T6 Aluminium Tube Standards and Specifications

6082 T6 tubes comply with a range of international standards for forged aluminum products, including:

- EN 755-2: Extruded rod/bar, tube, and profiles – Mechanical properties

- EN 754-2: Cold drawn rod/bar and tube – Mechanical properties

- EN 573-3: Chemical composition and forms of wrought products

- EN 485-2: Sheet, strip, and plate – Mechanical properties

- ISO 6361: Wrought aluminum and aluminum alloy sheets, strips, and plates

6082 T6 Aluminium Tube Typical Size Range

Commercial 6082 T6 tubes are available in a variety of outer diameters (e.g., 10 mm to 150 mm) and wall thicknesses (1 mm to 25 mm). Common stock sizes include 35 mm outer diameter × 2 mm wall thickness and 40 mm outer diameter × 3 mm wall thickness, as well as custom sizes in accordance with EN 755-2 tolerance requirements.

Standards and Dimensions

Standards: Complies with EN 755, BS L100, AS9100, and DIN 3.2315 standards.

Stock Dimensions:

- Round tube: Outer diameter 6–120 mm, wall thickness 0.5–3 mm.

- Square/rectangular tube: Side length up to 200 mm, wall thickness 2–5 mm.

6082 T6 Aluminium Tube Chemical Composition

6082 aluminum alloy belongs to the wrought aluminum-magnesium-silicon-manganese series. It typically contains (by weight) 0.6–1.2% magnesium, 0.7–1.3% silicon, 0.4–1.0% manganese, a maximum of 0.5% iron, 0.25% chromium, 0.1% copper, 0.1% titanium, 0.2% zinc, and other residuals up to 0.15%; the remainder being aluminum (95.2–98.3%).

| Element | Percentage (%) | Role in Alloy |

| Aluminum (Al) | Balance (~95–98%) | Base material |

| Magnesium (Mg) | 0.6–1.2 | Enhances strength via Mg₂Si precipitates |

| Silicon (Si) | 0.7–1.3 | Forms Mg₂Si for hardening |

| Manganese (Mn) | 0.4–1.0 | Controls grain structure |

| Chromium (Cr) | ≤0.25 | Improves corrosion resistance |

| Iron, Copper, Zinc | ≤0.5 (total) | Minimize impurities. |

Physical Properties of 6082 T6 Aluminium Tube

- Density: 2.70 g/cm³

- Thermal Conductivity: ~180 W/m·K

- Melting Range: 585 °C to 650 °C

- Young's Modulus: 71 GPa

- Coefficient of Thermal Expansion: 23.1 μm/m·K

Mechanical Properties of 6082 Aluminium Tube (T6 Temper)

- Standard extruded/drawn tube (wall thickness 5–25 mm)

- Yield Strength: ≥ 260 MPa

- Tensile Strength: ≥ 310 MPa

- Elongation (A₅₀ mm): ≥ 8%

- Brinell Hardness: ~95 HB

Strength Performance: Highest strength among 6000 series aluminium alloys, suitable for high-stress applications such as trusses, cranes, and marine structures.

Typical Commercial Tube Examples

- 35 mm OD × 2 mm wall thickness: Tensile strength ≥ 290 MPa, Hardness 95 HB

- 40 mm OD × 3 mm wall thickness: Tensile strength ≥ 290 MPa, Hardness 95 HB

Heat Treatment and Manufacturing of 6082 T6 Aluminium Tube

- T6 Temper Definition: T6 indicates the alloy has been solution heat-treated and artificially aged to maximize strength while maintaining reasonable ductility.

- Manufacturing Method: 6082 T6 tubes are typically produced via extrusion or cold drawing, enabling the production of thin-walled and dimensionally precise complex profiles.

Corrosion Resistance and Surface Treatment of 6082 T6 Aluminium Tube

The 6082 alloy, due to its balanced Mg-Si-Mn chemical composition, exhibits excellent corrosion resistance, especially in marine and industrial environments; additionally, it is easily anodized, enhancing surface protection and aesthetics.

Processing Technology of 6082 T6 Aluminium Tube

- Slightly inferior surface finish during extrusion compared to other alloys in the same series; forming of thin-walled complex profiles is more difficult.

- Excellent machinability, good chip breakability in T6/T651 temper, suitable for precision component manufacturing.

Applications of 6082 T6 Aluminium Tube in the Aerospace Field

- Aircraft fuel lines, hydraulic pipelines, and other fuselage components, fully utilizing its strength, light weight, and corrosion resistance.

- Fuel tanks, fuselage structures, landing gear components.

- Auxiliary structures for aircraft landing gear, aerospace fixtures.

Applications of 6082 T6 Aluminium Tube

| Industry Sector | Specific Application Scenarios |

| Transportation | Truck chassis components, marine pipelines, structural parts for rail vehicles |

| Construction Engineering | Bridge support tubes, curtain wall frames, tower crane booms |

| Industrial Equipment | Hydraulic pistons, valve fittings, inner lining tubes for beer/milk mixers |

- Construction: bridges, cranes, roof trusses.

- Transportation: truck frames, railway carriages.

- Industry: hydraulic systems, ore buckets, beer kegs.

- Structural and Load-Bearing: due to its high strength-to-weight ratio, suitable for trusses, bridges, cranes, transport frames, and ore buckets.

- Industrial: beer kegs, milk mixers, and pressure vessel components for high-stress applications.

Manufacturing Process and Limitations of 6082 T6 Aluminium Tube

- Weldability: Suitable for gas/arc welding, but strength in the heat-affected zone (HAZ) is reduced. Use of 4043 filler wire is recommended for optimal results.

- Machinability: Capable of producing tight chip curls in T6 temper and can be equipped with chip breakers.

- Extrusion Process Challenges: Difficult to extrude thin-walled or complex shapes; surface finish is rougher compared to 6063.

Comparison and Advantages of 6082 T6 Aluminium Tube

- Compared with 6061 Alloy: 6082-T6 has higher strength and better corrosion resistance, though it is more quench-sensitive; more suitable for marine environments and heavy-load structures.

- Surface Treatment: Excellent anodizing properties, supports dyeing, coating, and other secondary processing; widely used in decorative industrial components.

Comparison with Similar Alloys

| Feature | 6082-T6 | 6061-T6 | 6063-T6 |

| Strength | Highest (340 MPa) | Moderate (310 MPa) | Low (241 MPa) |

| Extrudability | Moderate | Good | Excellent |

| Applications | Structural | General-purpose | Aesthetic |