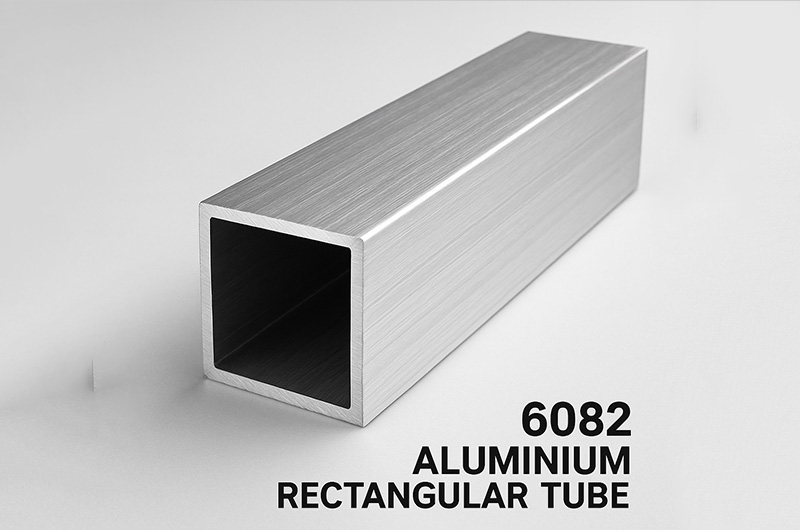

6082 Aluminium Rectangular Tube

6082 aluminium rectangular tube is a rectangular cross-section tube made from 6082 aluminium alloy through a hot extrusion process. This material combines the excellent properties of 6082 aluminium alloy and has wide applications in industrial and architectural fields.

In the T6 heat-treated condition, 6082 aluminium rectangular tube exhibits high strength. Its strength ranks among the top within the 6000 series aluminium alloys, making it a suitable substitute for certain 6061 aluminium alloy applications.

6082 aluminium rectangular tube is made from a medium-strength Al-Mg-Si alloy. Due to its high manganese content (which refines the grain structure), it has the highest strength in the 6000 series.

The rectangular tube is extruded according to EN 755-8 standard with strict dimensional tolerances (±0.25-0.90 mm, depending on size). This alloy offers excellent corrosion resistance and weldability, making it an ideal choice for structural, marine, automotive, and aerospace frames and components.

6082 Aluminium Rectangular Tube Surface Properties

- Excellent anodizing effect, facilitating surface treatment

- Outstanding oxidation and corrosion resistance, suitable for humid and salt-spray environments

Surface Treatment

- Anodizing: commonly used to enhance appearance and corrosion resistance.

- Powder coating/painting: provides decorative and chemically resistant layers.

- Mechanical polishing/brushing: suitable for architectural or consumer-facing components.

6082 Aluminium Rectangular Tube Stock Size

| Description | Width(W) | Height(H) | Wall thickness(T) |

| 1" X 2" X 0.035" 6082 Aluminium Rectangular Tube | 1" | 2" | 0.035" |

| 1" X 3" X 0.035" 6082 Aluminium Rectangular Tube | 1" | 3" | 0.035" |

| 1" X 4" X 0.049" 6082 Aluminium Rectangular Tube | 1" | 4" | 0.049" |

| 1" X 6" X 0.25" 6082 Aluminium Rectangular Tube | 1" | 6" | 0.25" |

| 2" X 4" X 0.058" 6082 Aluminium Rectangular Tube | 2" | 4" | 0.058" |

| 2" X 6" X 0.065" 6082 Aluminium Rectangular Tube | 2" | 6" | 0.065" |

| 2" X 8" X 0.049" 6082 Aluminium Rectangular Tube | 2" | 8" | 0.049" |

| 2" 10" 0.095" 6082 Aluminium Rectangular Tube | 2" | 10" | 0.095" |

| 3" X 6" X 0.049" 6082 Aluminium Rectangular Tube | 3" | 6" | 0.049" |

| 4" X 2" X 0.125" 6082 Aluminium Rectangular Tube | 4" | 2" | 0.125" |

| 4" X 2" X 0.250" 6082 Aluminium Rectangular Tube | 4" | 2" | 0.250" |

| 4" X 6" X 0.065" 6082 Aluminium Rectangular Tube | 4" | 6" | 0.065" |

| 6" X 2" X 0.125" 6082 Aluminium Rectangular Tube | 6" | 2" | 0.125" |

| 6" X 2" X 0.250" 6082 Aluminium Rectangular Tube | 6" | 2" | 0.250" |

| 6" X 3" X 0.375" 6082 Aluminium Rectangular Tube | 6" | 3" | 0.375" |

6082 Aluminium Rectangular Tube Standards

Compliant with BS L114, EN 755, and AS9100 standards, ensuring quality for aerospace and structural applications.

- EN 573-3: Chemical composition and shape

- EN 755-2 / -8: Mechanical properties and tolerances for extruded products

- ISO 6361: Mechanical properties of sheets/plates (relevant shapes)

6082 Aluminium Rectangular Tube Extrusion and Dimensional Tolerances

Rectangular tubes are extruded per EN 755-8:2008, with tolerances on width and depth as follows:

- Cross-section ≤ 100 mm: ± 0.25 mm (Column I) / ± 0.40 mm (Column II)

- 100–200 mm: ± 0.30 mm / ± 0.50 mm

- 200–300 mm: ± 0.40 mm / ± 0.70 mm

- 300–350 mm: ± 0.50 mm / ± 0.80 mm

Thickness tolerances vary similarly, ensuring consistency for structural assemblies.

6082 Aluminium Rectangular Tube Heat Treatment States

- T4: Solution heat-treated and naturally aged - medium strength, good formability.

- T6: Solution heat-treated and artificially aged - maximum strength, medium ductility.

Common conditions include:

- T6: Highest strength, solution heat-treated and artificially aged.

- T4: Naturally aged, enhancing ductility.

- O: Annealed, improving formability.

- Stock dimensions: Wall thickness 2-25 mm, maximum length 6 meters.

6082 Aluminium Rectangular Tube Fabrication and Machinability

- Machinability: Excellent performance in T6 and T651 temper, produces tight chips and features chip breakers.

- Weldability: Good, but strength in the weld zone may decrease. Best results are achieved with 4043 or 5356 filler wire.

- Formability: Best bending and cold-working properties in O (annealed) or T4 temper.

- Surface finish: Extruded surface is not as smooth as other 6000 series alloys, but anodizing treatment works well.

- Joining: Can be welded, brazed, and soldered, but may require post-weld heat treatment to restore strength.

6082 Aluminium Rectangular Tube Corrosion Resistance

6082 exhibits excellent corrosion resistance in atmospheric, industrial, and marine environments due to its stable Mg₂Si precipitates and protective oxide film. It is commonly used in outdoor structures and marine components without the need for additional coatings.

6082 Aluminium Rectangular Tube Processing Adaptability

- Good weldability and cold formability, supports processes such as TIG/MIG welding.

- Good machinability, can form tight chips when using chip breakers.

6082 Aluminium Rectangular Tube Core Advantages

Structural Performance

The addition of manganese controls grain structure, improving the overall strength of the material, making it especially suitable for high-stress structural components. It maintains workability in the annealed state, facilitating secondary processing.

Lightweight Design

With a density of just 2.7g/cm³, it reduces weight by about 65% compared to steel structures, significantly improving payload efficiency in shipbuilding and transportation equipment.

Process Adaptability

The use of dual-stage filtration casting process (foam ceramic + glass fiber filtering) ensures the material's internal purity.

Extrusion molding requires strict control of temperature (735-745°C) and speed, making it suitable for producing rectangular tubes with wall thicknesses ≥2mm.

6082 Aluminium Rectangular Tube Aerospace Advantages

| Advantage | Significance in Aerospace |

| Medium strength and good fatigue performance | Meets the strength and lifespan requirements for non-load-bearing components |

| Good corrosion resistance | Suitable for high-humidity, high-salt environments, reducing maintenance costs |

| Excellent weldability | Improves assembly efficiency in aerospace applications |

| Relatively low cost | Suitable for mass production of non-critical components, controlling costs |

| Good machinability | Suitable for precision machining, applicable to complex joint structures |

6082 Aluminium Rectangular Tube in Aerospace Applications

The 6082 aluminium rectangular tube is widely used in the aerospace industry due to its excellent mechanical properties, weldability, corrosion resistance, and moderate strength.

| Application Area | Specific Use | Description |

| Structural Support Components | Cabin Partition Walls | Utilizing the structural advantages of rectangular sections to enhance bending stiffness and effectively reduce weight, it is one of the commonly used materials in non-critical load-bearing components. |

| Equipment Support Framework | ||

| Beams or Longitudinal Beams in Door Structures | ||

| Seat Frames and Cabin Installations | Aircraft Seat Frames | The excellent weldability and corrosion resistance of 6082 make it suitable for internal structural components that require repeated assembly and long service life, extending the lifespan of the parts. |

| Backrest Brackets | ||

| Baggage Compartment Installations | ||

| Ground Support Equipment (GSE) Components | Ground Maintenance Platforms | The good impact resistance and moderate strength of 6082 ensure the safety of ground equipment structures, while the tube section facilitates quick assembly and maintenance. |

| Boarding Stair Structure Components | ||

| Aircraft Cargo Support Frames |

Other Industries where 6082 Aluminium Rectangular Tube is Applied

| Application Scenario | Specific Use Case | Performance Requirements Matching Points |

| Engineering Structures | Bridge Trusses, Crane Arms, Building Curtain Walls | High Specific Strength + Weather Resistance |

| Transport Vehicles | Ship Bulkheads, Rail Vehicle Frames, Truck Chassis | Lightweight + Fatigue Resistance |

| Machinery Equipment | Hydraulic Cylinder Sleeves, Conveyor Guide Rails, Mining Machine Supports | Wear Resistance + Dimensional Stability |

| Special Equipment | Beer Fermentation Tanks, Milk Stirrer Cylinders | Food-grade Corrosion Resistance |

- Structural Frameworks and Supports: Bridges, Towers, Trusses, Scaffolding.

- Marine and Shipbuilding: Railings, Masts, Saltwater-resistant Deck Structures.

- Automotive and Transportation: Chassis Components, Roll Cages, Load-bearing Tracks.

- Aerospace: Fuel Lines, Support Rods, Fuselage Frames — made from drawn T6 tubes.

- General Engineering: Hydraulic Manifolds, Industrial Automation Frames, Building Facades.

- Structural Engineering: Bridges, Cranes, Trusses, and Roofs.

- Industrial and Consumer Goods: Milk Mixers, Beer Barrels, Furniture, and Railings.

Advantages of 6082 Aluminium Rectangular Tube Over Competing Alloys

- Higher Strength: Outperforms 6061 alloy, making it more suitable for high-stress applications.

- Cost-Effective: Widely available in the UK, reducing lead times and lowering costs.

- Versatility: Suitable for machining, welding, and anodizing.

Key Considerations

- Thin-Walled Extrusions: Due to the alloy’s quenching process limitations, production is more challenging.

- Aesthetic Limitations: Rough extrusion surfaces may require post-treatment for decorative applications.