6082 T6 T651 Aerospace Grade Aluminum Sheet Plate

6082 aluminum alloy plate belongs to the Al-Mg-Si series heat-treatable strengthening alloys and is an important structural material in the aerospace and high-end industrial sectors. As one of the representative alloys of the 6××× series, 6082 aluminum sheet occupies an important position in multiple fields due to its excellent comprehensive properties.

6082 aluminum sheet is a heat-treatable aluminum alloy plate whose main alloying elements are magnesium, silicon, and manganese. Compared with 6061 alloy, 6082 has higher strength and better welding performance, making it one of the most widely used aluminum alloys in Europe.

The development of 6082 alloy originated from the demand for higher-strength aluminum alloys. With the increasing requirements for lightweight and high strength in fields such as aerospace, high-speed trains, and shipbuilding, 6082 aluminum alloy has gradually become an alternative to 6061 alloy due to its excellent comprehensive performance.

6082 aerospace-grade aluminum plate, with its excellent comprehensive properties, has become an important structural material in aerospace and high-end industrial fields. Its high strength, lightweight characteristics, good corrosion resistance, and weldability make it widely used in many areas.

6082 alloy exhibits good corrosion resistance in many environments, especially after anodizing treatment, which can further enhance its corrosion resistance.

6082 Aerospace-Grade Aluminum Sheet Specifications and Tempers

The specifications for 6082 aerospace grade aluminum plate

| Alloy | 6082 |

| Temper | O, T4, T6, T651, T6511 etc. |

| Thickness | 0.5mm-300mm |

| Width | 500-2650mm |

| Length | 500-12000mm |

| Surface treatment | smooth, anodized, or coated (e.g., powder coating for aesthetic purposes). |

Common Tempers of 6082 Aerospace-Grade Aluminum

| Temper | Process Description | Main Characteristics | Application Scenarios |

| O | Annealed condition | Low strength, high plasticity, easy to process | Situations requiring high formability |

| T4 | Solution heat-treated and naturally aged | Medium strength, good toughness | Structural parts, bent formed components |

| T6 | Solution heat-treated and artificially aged | High strength, high hardness | Structural components requiring high strength |

| T651 | Solution heat-treated + artificially aged + stress-relieved by stretching | High strength, good flatness | Machined parts, precision structural parts |

Characteristics of 6082 Aerospace-Grade Aluminum Plate

- Outstanding Strength: 6082 has significantly higher strength than conventional industrial aluminum alloys (approximately 20% improvement), capable of meeting the stringent load-bearing standards of aerospace structures and providing solid support for overall aircraft stability.

- Excellent Formability and Processability: 6082 aerospace-grade aluminum possesses good adaptability to forging, rolling, drawing, stamping, and other processes, enabling efficient manufacturing of complex-shaped aerospace components, matching diverse design requirements.

- Excellent Corrosion Resistance: Even under long-term service in harsh environments, 6082 aerospace-grade aluminum can maintain stable material properties, effectively resist corrosion attacks, and thus significantly extend the service life cycle of aerospace equipment.

- Good Welding Compatibility: Compatible with various mainstream welding processes such as gas shielded welding, arc welding, and laser welding. The resulting welds have high strength and reliability, meeting the requirements of various critical connection scenarios in the aerospace field.

- Ideal Surface Treatment Effects: Capable of undergoing anodizing, electrophoretic painting, and other surface treatment processes. While enhancing corrosion resistance, it also significantly improves the appearance quality of components, in line with the strict surface requirements of aerospace equipment.

- Significant Lightweight Advantage: Thanks to its relatively low density (2.7 g/cm³), about one-third lighter than traditional steel materials, it effectively reduces the aircraft's own weight, enhances payload capacity, and improves overall operational efficiency.

- Excellent Surface Quality and Mechanical Properties: 6082 aerospace-grade aluminum offers good surface smoothness and flatness to meet high appearance standards; meanwhile, its excellent mechanical properties allow it to withstand high stress and heavy loads, providing critical support for the safe and reliable operation of aerospace equipment.

The chemical composition of 6082 aviation aluminum sheet plate

| Element | Composition(%) |

| Si | 0.7-1.3 |

| Fe | 0.50 |

| Cu | 0.10 |

| Mn | 0.40-1.00 |

| Mg | 0.06-1.20 |

| Cr | 0.25 |

| Zn | 0.20 |

| Ti | 0.10 |

| Al | Remainder |

The typical mechanical performance of 6082 T6 aircraft aluminum sheet plate

| Material | Thickness (mm) | Tensile strength (N/mm2) min | Yield strength (N/mm2) min | Elongation on 50mm % (min) |

| Alloy 6082 T6 Sheet and Plate | 0.2-3.0 | 295 | 255 | 8 |

| Alloy 6082 T6 Sheet and Plate | 3.0-6.0 | 295 | 240 | 8 |

| Alloy 6082 T6 Sheet and Plate | 6.0-25.00 | 295 | 240 | 8 |

6082 T6 T651 aluminum plate physical properties

| Temper | T6 | T651 |

| Density | 2.70 g/cm³ | 2.68g/cm³ |

| Tensile Strength | 250-310MPa | >=295MPa |

| Elongation | 10% | 8% |

| Thermal Conductivity | 170 W/m-K | 220.0 W/m-K |

Haomei Aluminum supplies 6082 aluminum plates

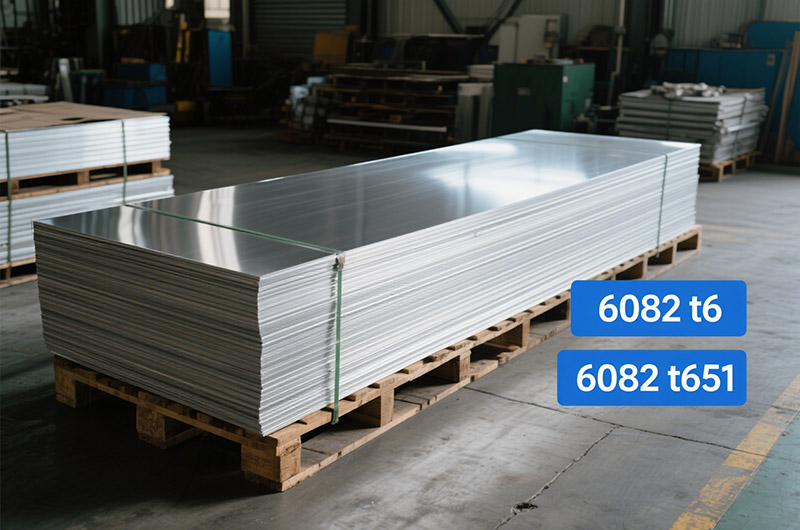

Aluminium 6082 T6 plate

T6 refers to the heat treatment condition, which includes solution heat treatment followed by aging to improve strength.

Characteristics: It offers excellent strength, corrosion resistance, and good machinability. It is widely used in applications that require high strength and excellent fatigue resistance.

Applications: Commonly used in structural applications such as bridges, cranes, and other machinery, where strength and good surface finish are important. In the aerospace industry, 6082 T6 aluminum plates are often used for making fuselage structures, wing structures, propellers, etc.

Aluminium Alloy 6082 T4 Plate

T4 is a condition where the alloy undergoes solution heat treatment followed by natural aging to achieve a stable state. It has good strength but is lower than T6.

Characteristics: It offers good machinability and excellent weldability. It also provides a balance of strength and flexibility, but with lower strength than T6.

Applications: Typically used in applications requiring formability and moderate strength, such as vehicle frames and other lightweight structures in the transportation industry. In the aerospace field, 6082 T4 aluminum plates are often used for making structural parts with lower strength requirements, such as cabin interiors and seat structures.

6082-T651 Aluminum Plate

T651 is similar to T6, but it includes a stress-relieving process that reduces residual stress caused by machining. This gives the plate better dimensional stability and excellent surface finish.

Characteristics: It has the same high strength and corrosion resistance as T6 but offers better machinability and lower internal stress.

Applications: Used in aerospace, marine, and automotive industries for structural parts requiring high strength, precision, and dimensional accuracy.

In general, 6082 aluminum is a versatile alloy suitable for applications requiring good strength, durability, and corrosion resistance. Different conditions (T4, T6, T651) offer varying balances of strength, formability, and stability.

Aerospace Applications of 6082 Aluminum Sheet

In the aerospace field, 6082 aerospace-grade aluminum plate is widely used due to its high strength and lightweight characteristics:

- Non-load-bearing aircraft structural parts: such as aircraft doors, interior decorative panels, seat structures, mainly using T4 temper 6082 aluminum sheet

- Aircraft structural components: including fuselage skins, wing assemblies, and flight control systems, mainly using T6/T651 temper 6082 aluminum sheet

- Aerospace equipment: used to manufacture structural parts of satellites, missiles, and rockets

- Precision parts: used to manufacture precision components such as aircraft landing gear pads, hinge heads, magnetic heads, brake pistons, and hydraulic pistons

- Aviation instruments and equipment: used for parts and brackets of aviation instruments and equipment, providing good rigidity and corrosion resistance

The application of 6082 aluminum alloy in the aerospace field benefits from its high strength, high toughness, and excellent corrosion resistance, meeting the strict material requirements of the aerospace industry. In particular, 6082 aluminum alloy forgings, due to their excellent strength, toughness, durability, and high-precision machining characteristics, have become the ideal material for manufacturing aerospace structural components and precision parts.

Haomei 6082 T6 T651 aluminum plate in stock

| Procuct | Thickness (in) | Size (in) |

| ASTM B209 1/4" 6082 T6 Aluminum Plate 12" x 24" | 1/4" | 12" x 24" |

| ASTM B209 1/4" 6082 T651 Aluminum Plate 12" x 36" | 1/4" | 12" x 36" |

| ASTM B209 3/8" 6082 T6 Aluminum Plate 12" x 24" | 3/8" | 12" x 24" |

| ASTM B209 3/8" 6082 T651 Aluminum Plate 12" x 36" | 3/8" | 12" x 36" |

| ASTM B209 1/2" 6082 T6 Aluminum Plate 12" x 24" | 1/2" | 12" x 24" |

| ASTM B209 1/2" 6082 T651 Aluminum Plate 12" x 48" | 1/2" | 12" x 48" |

| ASTM B209 5/8" 6082 T6 Aluminum Plate 12" x 36" | 5/8" | 12" x 36" |

| ASTM B209 5/8" 6082 T651 Aluminum Plate 24" x 24" | 5/8" | 24" x 24" |

| ASTM B209 3/4" 6082 T6 Aluminum Plate 12" x 36" | 3/4" | 12" x 36" |

| ASTM B209 3/4" 6082 T6 Aluminum Plate 12" x 48" | 3/4" | 12" x 48" |

| ASTM B209 3/4" 6082 T6 Aluminum Plate 24" x 24" | 3/4" | 24" x 24" |

| ASTM B209 1" 6082 T651 Aluminum Plate 12" x 12" | 1" | 12" x 12" |

| ASTM B209 1" 6082 T651 Aluminum Plate 12" x 24" | 1" | 12" x 24" |

| ASTM B209 1" 6082 T651 Aluminum Plate 12" x 36" | 1" | 12" x 36" |

| ASTM B209 1" 6082 T651 Aluminum Plate 24" x 24" | 1" | 24" x 24" |

| ASTM B209 1.25" 6082 T6 Aluminum Plate 12" x 12" | 1.25" | 12" x 12" |

| ASTM B209 1.25" 6082 T6 Aluminum Plate 12" x 24" | 1.25" | 12" x 24" |

| ASTM B209 1.25" 6082 T6 Aluminum Plate 12" x 48" | 1.25" | 12" x 48" |

| ASTM B209 1.25" 6082 T6 Aluminum Plate 24" x 24" | 1.25" | 24" x 24" |

| ASTM B209 1.25" 6082 T6 Aluminum Plate 24" x 36" | 1.25" | 24" x 36" |

| ASTM B209 1.5" 6082 T6 Aluminum Plate 12" x 24" | 1.5" | 12" x 24" |

| ASTM B209 1.5" 6082 T651 Aluminum Plate 12" x 48" | 1.5" | 12" x 48" |

| ASTM B209 1.5" 6082 T651 Aluminum Plate 24" x 24" | 1.5" | 24" x 24" |

| ASTM B209 1.5" 6082 T651 Aluminum Plate 24" x 36" | 1.5" | 24" x 36" |

| ASTM B209 1.75" 6082 T651 Aluminum Plate 12" x 12" | 1.75" | 12" x 12" |

| ASTM B209 1.75" 6082 T651 Aluminum Plate 12" x 36" | 1.75" | 12" x 36" |

| ASTM B209 1.75" 6082 T651 Aluminum Plate 12" x 48" | 1.75" | 12" x 48" |

What to Consider When Purchasing 6082 Aerospace Aluminum Sheet?

Supplier Selection Criteria

- Qualification and Certification: The supplier should possess relevant industry qualifications and certifications such as ISO 9001 and AS9100

- Production Capability: Evaluate the supplier’s equipment, technical capabilities, and production capacity

- Industry Experience: Give priority to suppliers with rich experience in the industry

- Technical Support: Suppliers should be able to provide comprehensive technical support

- After-Sales Service: A good after-sales service system can promptly resolve issues during use

Key Points for Quality Inspection

- Material Certification Documents: Quality certification documents and heat treatment status certificates

- Appearance Inspection: Surface quality, oxide film quality, edge quality

- Dimensional Accuracy Check: Thickness, width, length, flatness

- Performance Testing: Hardness test, tensile test

Contract Clause Focus

- Product Specifications: Clearly list product material, temper condition, dimensional specifications, etc.

- Quality Standards: Specify applicable product standards such as ASTM, EN, GB, etc.

- Inspection and Acceptance: Specify inspection methods, acceptance criteria, and handling methods for non-conforming products

- Packaging and Transportation: Define packaging methods, labeling requirements, and transportation methods

General Infos About 6082 Aluminum Sheet

Advantages/Disadvantages of 6082 Aluminum Sheet

Advantages of 6082 Aluminum Sheet

- High Strength: The tensile strength of 6082-T6 condition can reach 310–340 MPa.

- Lightweight: Density is approximately 2.7 g/cm³, much lower than steel materials.

- Excellent Corrosion Resistance: Performs well especially in marine environments or industrial atmospheres.

- Outstanding Weldability: Suitable for TIG, MIG and other welding methods.

- Good Workability: Offers excellent formability and machinability.

Disadvantages of 6082 Aluminum Sheet

- High Quenching Sensitivity: Requires strict control over quenching speed and cooling conditions.

- Relatively Difficult to Process: More challenging to machine compared to lower strength aluminum alloys.

- Post-Weld Heat Treatment Required: Needs solution treatment and artificial aging after welding.

- Susceptible to Stress Corrosion Cracking: May occur under certain specific conditions.

- Relatively Expensive: Higher price due to its high-performance characteristics.

Processing Characteristics of 6082 Aluminum Sheet

- Heat Treatment Process The heat treatment process directly affects the final properties of 6082 aluminum sheet. It mainly includes smelting, purification and casting, solution treatment, quenching, aging treatment, and stress-relief treatment.

- Machinability In T6/T651 condition, 6082 has good cutting performance, but due to the stickiness of aluminum, tools tend to get aluminum adhesion. It is recommended to use sharp tools, low rotation speed, and high feed rate.

- Weldability 6082 aluminum sheet offers good weldability, suitable for TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) arc welding methods. Strength in the heat-affected zone after welding will decrease, requiring re-heat treatment to restore performance.

- Surface Treatment 6082 aluminum sheet can be enhanced in performance and aesthetics through various surface treatments including anodizing, painting, chemical oxidation, mechanical surface processing, and coloring.

Standards for 6082 Aluminum Sheet

- International Standard (ISO): ISO 209.1-1989, ISO 6361

- Chinese National Standard (GB): GB/T 3190-2008, GB/T 3880-2006, GB/T 3191-2010

- European Standard (EN): EN 573-3-1994, EN 485-2, EN 754-2

- American Standard (ASTM/AA): ASTM B209, AA/UNS A96082

Equivalent Grades of 6082 Aluminum Sheet

| Country/Region | Standard Number | Grade |

| China | GB/T 3190-2008 | 6082 |

| International Organization for Standardization | ISO 209.1-1989 | Al SiMgMn |

| Europe | EN 573-3-1994 | EN AW-6082/AlSiMgMn |

| Germany | DIN1725.1-1986 | AlMgSi/3.2315 |

| France | NF A50-411 | 6082 (A-SGMO0.7) |

| United States | AA/UNS | 6082/A96082 |

In Which Fields is 6082 Aluminum Sheet Applied?

Applications in the Transportation Sector

6082 aluminum sheet is widely used in the transportation sector:

- Automotive Industry: Used for vehicle body structural parts, truck chassis, shock absorber components, etc., to reduce vehicle weight and improve fuel efficiency.

- High-Speed Rail: Used as structural material for high-speed train car bodies, taking advantage of its high strength and lightweight characteristics.

- Shipbuilding: Applied in hull structures, ship decks, and other ship parts, especially for high-speed vessels, utilizing its medium strength, excellent corrosion resistance, and lightweight.

- Rail Vehicles: Used for structural and decorative parts of rail transport vehicles.

- Transportation Equipment: Structural material for cranes, transport aircraft, transport ships, etc.

The use of 6082 aluminum sheet in the transportation sector helps achieve lightweight designs, improve energy efficiency, while ensuring structural strength and safety. In shipbuilding, 6082 aluminum alloy is particularly suitable for hull structures, ship plates, and other components due to its excellent corrosion resistance and strength.

Applications in the Industrial and Construction Sectors

6082 aluminum sheet also performs excellently in industrial and construction fields:

- Industrial Equipment: Used in the manufacture of pressure vessels, high-pressure tanks, liquid storage tanks, and other industrial devices.

- Mechanical Structures: Used as material for mechanical structures including bars, plates, tubes, and profiles.

- Building Structures: Applied in bridges, cranes, roof frameworks, and other building components.

- Sporting Equipment: For high-stress sporting goods like bicycle frames, climbing gear, etc.

- Mold Manufacturing: Used to produce industrial molds and mechanical equipment.

- Decorative Applications: In architectural decoration, camera lenses, and other applications requiring aesthetics and high strength.

The use of 6082 aluminum sheet in industry is mainly based on its high strength, good machinability, and corrosion resistance. In the construction field, 6082 aluminum sheet is suitable for bridge decorations, structural building components, etc., offering excellent strength and aesthetics.

Other Application Fields

In addition to the main applications above, 6082 aluminum sheet is also widely used in the following fields:

- Electronics and Electrical: Used in the production of electronic parts, connectors, electrical components, and valve parts.

- Optical Instruments: For camera lenses and other optical instrument components.

- Hardware Products: Such as hinges, couplings, ship accessories, and hardware fittings.

- Handicrafts: Used to manufacture crafts due to its good workability and surface treatment capabilities.

- Special Containers: Such as beer barrels, milk containers, and other liquid vessels.

The versatility of 6082 aluminum sheet enables it to meet the requirements of various application scenarios, ranging from high-strength structural parts to precision components, demonstrating excellent adaptability.

Comparison Between 6082 Aluminum and Other Aluminum Alloys

| Property | 6082 | 6061 | 7075 | 5052 |

| Main Alloying Elements | Mg, Si, Mn | Mg, Si | Zn, Mg, Cu | Mg |

| Tensile Strength (MPa) | 310–340 | 240–260 | 500–570 | 190–210 |

| Yield Strength (MPa) | 260–290 | 215–240 | 430–500 | 125–150 |

| Elongation (%) | 10 | 12 | 11 | 12 |

| Density (g/cm³) | 2.7 | 2.7 | 2.8 | 2.7 |

| Corrosion Resistance | Good | Good | Moderate | Excellent |

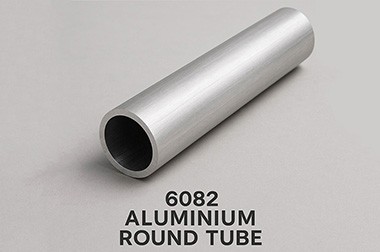

6082 Aluminum Sheet Similar Specifications

- BS L111 Alloy 6082-T6 Bars and Sections

- BS L112 Alloy 6082 Forging Stock and Forgings

- BS L113 Alloy 6082-T6 Sheet and Strip

- BS L114 Alloy 6082-T6 Tube Drawn

- BS L115 Alloy 6082-T651 Plate

- BS HE30 6082 Extrusions

- BS HP30 6082 Plate

- BS HT30 6082 Tube

- BS HG30 6082 Wire

- BS HS30 6082 Sheet

- EN 2326 6082-T6 Extruded bar

- EN 2636 6082-T6 Bar