6082 T6 Aerospace Grade Aluminum Bar

6082 aluminum alloy is a widely used medium-strength wrought alloy in the 6xxx (Mg-Si) series, praised for its good mechanical properties, excellent corrosion resistance, and ease of machining. After heat treatment to T6/T651 condition, its strength is the highest among 6000 series alloys, making it a preferred structural alloy for bars, rods, tubes, and extruded profiles.

Due to its excellent strength and manganese content, 6082 aluminum bar has largely replaced 6061 in many industrial applications. Manganese refines the grain structure, thereby improving toughness.

6082 aluminum bar can significantly increase strength through heat treatment (T6 condition), and it offers excellent machinability, weldability, and corrosion resistance. Its composition is based on magnesium (Mg) and silicon (Si) as main alloying elements, with manganese (Mn) as an auxiliary strengthening element. It is widely used in high-stress applications such as construction, trusses, bridges, cranes, transportation, machinery manufacturing, and general engineering components.

6082 Aluminum Bar Heat Treatment and Tempers

6082 cannot be strengthened by cold work ("work-hardening") but responds well to heat treatment:

- T6: Solution-treated and artificially aged for maximum strength

- T651: T6 plus stress-relief by stretching (common in bar and billet form)

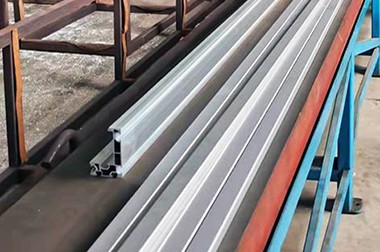

6082 Aluminum Bar Available Forms and Sizes

- Shapes: Round, square, flat, hexagonal bars

- Sizes (Round Bar): 6mm–1350mm diameter; lengths up to 6m

- Thickness (Flat Bar): 2–100mm

6082 Aluminum Bar Standards and Designations

6082 and its tempers are covered by multiple European and international standards:

- EN 573-3 / EN 485-2: Chemical composition & mechanical properties for sheets, strips, plates.

- EN 754-2 / EN 755-2: Mechanical properties for cold-drawn & extruded rod/bar, tube & profiles.

- ISO 6361: Wrought aluminium sheets, strips, plates.

- Alternate designations include AlSi1MgMn, 3.2315, H30, and A96082.

6082 Aluminum Bar Core Properties

| High Strength | 6082 aluminum alloy has good strength, suitable for bearing larger loads. |

| Machinability | Easy to extrude into complex cross-section profiles |

| Can be cut, polished, and anodized | |

| Weldability | Supports TIG and MIG welding processes |

| High joint strength | |

| Corrosion Resistance | Good resistance to atmosphere, fresh water, and mildly corrosive media |

| Can be enhanced via surface treatments such as anodizing | |

| Lightweight Advantage | Density is only 1/3 of steel, suitable for weight-sensitive applications |

| Heat Treatable | Strength can be increased through heat treatment, e.g., hardened in T6 temper |

Popular 6082 Aluminum Rods

6082 Aluminum Round Bar

The 6082 aerospace aluminum round bar is one of the most common shapes of aluminum bars, widely used in the manufacture of various mechanical parts and structural components. Due to its excellent mechanical properties and lightweight characteristics, it is suitable for aerospace, automotive, and general mechanical manufacturing applications.

6082 Aluminum Square Bar

The 6082 aerospace aluminum square bar is an aluminum bar with a square cross-section, commonly used in architectural decoration, mechanical part manufacturing, and other fields. Due to its square cross-section, the square bar offers superior performance in structural connections and support, often used in frame structures and component supports.

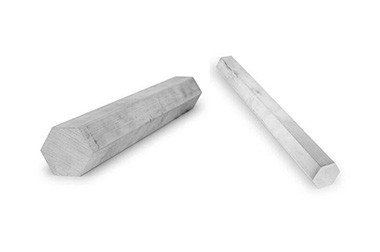

6082 Aluminum Hexagonal Bar

The 6082 aerospace aluminum hexagonal bar is an aluminum bar with a hexagonal cross-section, commonly referred to as a hex bar. This shape is often used to manufacture mechanical parts such as nuts and bolts, as well as other components requiring a hexagonal interface.

6082 Aluminum Flat Bar

The 6082 aerospace aluminum flat bar is an aluminum bar with a rectangular cross-section, where the width is greater than the thickness. It is primarily used for manufacturing parts requiring a flat shape. Due to its superior formability, the flat bar is commonly found in various special structural components in mechanical, automotive, and aerospace applications.

Haomei Aluminum produces 6082 aerospace aluminum bars according to the following standards: EN 573, EN 755, EN 754, ASTM B221, AMS 4156, EN 573-3, AMS QQ-A-200/9, AMS QQ-A-225/8, AS9100, NADCAP, JISQ 9100.

Chemical composition of 6082 aerospace aluminum bar

| Chemical composition | % |

| Al | 96.4%-98.8% |

| Cu | 0.6%-1.2% |

| Si | 0.7%-1.3% |

| Mg | 0.6%-1.2% |

| Mn | 0.4%-1.0% |

| Cr | 0.25%-0.35% |

| Zn | ≤0.2% |

| Ti | ≤0.1% |

Alloy temper of 6082 aerospace aluminum bar

| Temper | Tensile strength(MPa) | Field strength(MPa) | Elongation(%) |

| T6 | 295-390 | 240-330 | 8-10 |

| T6511 | 290-380 | 240-330 | 8-10 |

| T651 | 290-380 | 240-330 | 8-10 |

Physical properties of 6082 aerospace aluminum bar

| Physical properties | Value |

| Density | 2.70 g/cm3 |

| Elastic modulus | 70 GPa |

| Melting point | 555 °C |

| Coefficient of thermal expansion | 23.2×10-6/°C |

| Thermal conductivity | 201-218 W/mK |

| Conductivity | 30-36 MS/m |

| Tensile strength | 310 MPa |

| Yield strength | 260 MPa |

| Elongation | 8%-10% |

6082 Aluminum Bar Forming, Machinability and Welding

6082 is typically produced by extrusion, cold stamping, hot stamping, and rolling. Forging and cladding processes are also feasible but less common. As a wrought alloy, it is not used for casting. Its high manganese content refines the grain structure and improves strength and machinability. It is easier to machine than many high-strength alloys and can be easily welded with suitable filler metal. However, joint design should account for strength reduction in the heat-affected zone.

6082 Aluminum Bar Corrosion Resistance

Thanks to its balanced silicon-magnesium-manganese chemistry, 6082 offers excellent resistance to atmospheric and seawater corrosion — comparable to or even better than 6061, making it suitable for marine and outdoor structural applications.

6082 Aluminum Bar Fabrication Characteristics

- Machinability: Excellent in T6 temper, with tight chips and good chip breaking

- Weldability: Good with TIG/MIG methods, though strength may drop in the welded area. Recommended filler wires: 4043 or 5356

- Cold Formability: Limited ductility in T6 temper; risk of cracking during sharp bending. Solutions include pre-heating or using proper bend radius.

6082 Aluminum Bar in Aerospace Applications

Aircraft Structural Components

- Fuselage Frame: Used to manufacture the load-bearing frame of the aircraft fuselage, providing necessary strength and stability.

- Wing Spars and Ribs: In wing structures, 6082 aluminum bars can be used as wing spars and ribs to support the shape and load of the wings.

- Tail Section Structure: Used in the tail structures of aircraft to ensure stability during flight.

Components and Parts

- Brackets and Connectors: Used to connect different structural components, ensuring overall structural stability.

- Doors and Hatches: In aircraft doors and hatches, 6082 aluminum alloy provides a balance of lightness and strength.

- Landing Gear Components: Used in the manufacture of certain landing gear parts that bear large impacts and loads.

Aircraft Interior Components

- Seat Frames: Used in the structural framework of aircraft seats, providing strength and safety while maintaining a lightweight design.

- Interior Support Structures: Used to support aircraft cabin interiors, ensuring the stability and safety of interior components.

Control Surfaces and Systems

- Control Surface Structures: Used in the manufacture of control surfaces such as elevators and rudders, ensuring aircraft controllability during flight.

- Control Rods and Linkages: 6082 aluminum bars are used in the aircraft control system to manufacture control rods and linkages, which require high strength and good fatigue resistance.

Aircraft Fuel Tanks

Fuel Tank Structure: 6082 aluminum alloy can be used to manufacture brackets and pipes for aircraft fuel tanks, thanks to its good corrosion resistance, which can withstand fuel corrosion.

Other Industries Using 6082 Aluminum Bar

6082 bars (round, square, rectangular) are widely used in the following fields as machining stock and structural components:

- Bridges, trusses, and crane booms – high-stress structural components

- Transport equipment – trailer frames, railcars, ore hoppers

- Pressure vessels and tanks (e.g., beer kegs, milk mixers)

- General engineering parts – shafts, pins, washers, fittings

- Structural: Bridges, trusses, cranes

- Aerospace: Aircraft frames, engine components, and non-primary load-bearing parts

- Marine: Hulls and decks (corrosion protection needed)

- Construction Engineering: Bridge supports, roof frames, lifting equipment

Comparison of 6082 Aluminum with Similar Alloys

- Compared to 6061: 6082 has higher strength (up to 340 MPa vs. 310 MPa) but lower ductility. Corrosion resistance is similar.

- Compared to 6063: 6082 has higher strength, while 6063 is better for producing complex extrusions (e.g., window frames).

Limitations of 6082 Aluminum

- Weakness in weld zones: Strength reduction in heat-affected areas; welding should be done carefully

- High-temperature softening: Strength declines above 200°C

- Cold forming challenges: In T6 temper, cracking may occur unless heated or bend radius adjusted