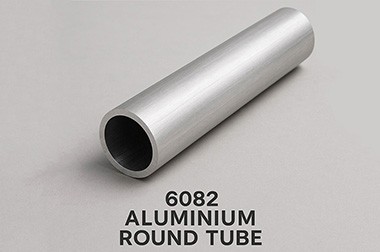

6063 Aluminum Tube

The 6063 aluminum tube is a tubular material made from 6063 aluminum alloy. It belongs to the Al-Mg-Si series, a medium-strength, heat-treatable alloy known for its lightweight, corrosion resistance, and high workability.

6063 aluminum tube is a widely used extrusion product, known for its excellent corrosion resistance, formability, and aesthetic appearance, making it the preferred choice for architectural and structural applications.

The 6063 aluminum tube is made from 6000 series alloy 6063, a heat-treatable magnesium-silicon alloy highly praised for its outstanding extrudability, good mechanical strength, high corrosion resistance, and superior surface finish. Its balanced composition makes it easy to extrude into tubes and other constant cross-sectional shapes, and then age-treated to achieve tempers such as T5 or T6. 6063 aluminum tube offers high strength and is suitable for applications in architecture, structures, automotive, and general tubing.

Haomei Aluminum manufactures high precision 6063 aluminum alloy tubes using core processing techniques of the aluminum-magnesium-silicon (6 series) alloy. These tubes feature high strength, corrosion resistance, and lightweight characteristics, meeting diverse demands across military, construction, automotive parts, aerospace, and other fields. Products include national standard aluminum tubes, ultra-hard aluminum tubes, thick-walled/thin-walled aluminum tubes, and large-diameter aluminum tubes. Multiple temper options such as T5, T6, and T52 are supported, suitable for scenarios such as tent supports, industrial pipelines, and mechanical components.

6063 Aluminum Tube Tempers and Heat Treatment

- T5: Cooled after extrusion and artificially aged to achieve medium strength

- T6: Solution heat treated and then artificially aged to achieve maximum strength

- T832: Solution heat treated, stress relieved by stretching, and then artificially aged to improve toughness

Different tempers can be customized to adjust strength, ductility, and residual stress for specific tubing applications.

6063 Aluminum Tube Standards and Specifications

Common standards covering 6063 aluminum tubes include:

- ASTM B221: Aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes

- BS EN 755-2: Aluminum and aluminum alloys extruded rod/bar, tube, and profiles

- ISO 6361: Wrought aluminum alloy sheets, strips, and plates

6063 aluminum tubes offer excellent extrudability, medium strength, superior corrosion resistance, and surface quality. Its flexible temper and surface treatment options enable wide applications in architectural, structural, and industrial tubing solutions.

Haomei 6063 Aluminum Tube Supply Availability

Size and shape: Available in round, square, and rectangular profiles with wall thicknesses ranging from 0.062 inches to 0.25 inches and diameters up to 6 inches.

6063-T52 Aluminum Round Tube Sizes

| Description | Outside Diameter (OD) | Wall Thickness |

| 0.500" × 0.065" 6063-T52 Aluminum Round Tube | 0.500" | 0.065" |

| 0.625" × 0.058" 6063-T52 Aluminum Round Tube | 0.625" | 0.058" |

| 0.750" × 0.065" 6063-T52 Aluminum Round Tube | 0.750" | 0.065" |

| 0.750" × 0.125" 6063-T52 Aluminum Round Tube | 0.750" | 0.125" |

| 0.875" × 0.065" 6063-T52 Aluminum Round Tube | 0.875" | 0.065" |

| 1.000" × 0.065" 6063-T52 Aluminum Round Tube | 1.000" | 0.065" |

| 1.000" × 0.125" 6063-T52 Aluminum Round Tube | 1.000" | 0.125" |

| 1.250" × 0.065" 6063-T52 Aluminum Round Tube | 1.250" | 0.065" |

| 1.250" × 0.090" 6063-T52 Aluminum Round Tube | 1.250" | 0.090" |

| 1.250" × 0.125" 6063-T52 Aluminum Round Tube | 1.250" | 0.125" |

| 1.375" × 0.065" 6063-T52 Aluminum Round Tube | 1.375" | 0.065" |

| 1.500" × 0.065" 6063-T52 Aluminum Round Tube | 1.500" | 0.065" |

| 1.500" × 0.090" 6063-T52 Aluminum Round Tube | 1.500" | 0.090" |

| 1.500" × 0.125" 6063-T52 Aluminum Round Tube | 1.500" | 0.125" |

| 1.750" × 0.125" 6063-T52 Aluminum Round Tube | 1.750" | 0.125" |

| 2.000" × 0.065" 6063-T52 Aluminum Round Tube | 2.000" | 0.065" |

| 2.000" × 0.125" 6063-T52 Aluminum Round Tube | 2.000" | 0.125" |

| 2.500" × 0.125" 6063-T52 Aluminum Round Tube | 2.500" | 0.125" |

| 3.000" × 0.083" 6063-T52 Aluminum Round Tube | 3.000" | 0.083" |

| 3.000" × 0.125" 6063-T52 Aluminum Round Tube | 3.000" | 0.125" |

| 3.500" × 0.065" 6063-T52 Aluminum Round Tube | 3.500" | 0.065" |

| 4.000" × 0.125" 6063-T52 Aluminum Round Tube | 4.000" | 0.125" |

| 5.000" × 0.125" 6063-T52 Aluminum Round Tube | 5.000" | 0.125" |

| 6.000" × 0.125" 6063-T52 Aluminum Round Tube | 6.000" | 0.125" |

| 7.000" × 0.064" 6063-T52 Aluminum Round Tube | 7.000" | 0.064" |

| 8.000" × 0.125" 6063-T52 Aluminum Round Tube | 8.000" | 0.125" |

6063 T52 Aluminum Square Tube Sizes

| Description | Outside Width × Height | Wall Thickness |

| 0.750" × 0.750" × 0.065" 6063 Aluminum Square Tube | 0.750" × 0.750" | 0.065" |

| 0.750" × 0.750" × 0.095" 6063 Aluminum Square Tube | 0.750" × 0.750" | 0.095" |

| 0.750" × 0.750" × 0.125" 6063 Aluminum Square Tube | 0.750" × 0.750" | 0.125" |

| 0.750" × 0.750" × 0.188" 6063 Aluminum Square Tube | 0.750" × 0.750" | 0.188" |

| 0.750" × 0.750" × 0.250" 6063 Aluminum Square Tube | 0.750" × 0.750" | 0.250" |

| 1.000" × 1.000" × 0.065" 6063 Aluminum Square Tube | 1.000" × 1.000" | 0.065" |

| 1.000" × 1.000" × 0.095" 6063 Aluminum Square Tube | 1.000" × 1.000" | 0.095" |

| 1.000" × 1.000" × 0.125" 6063 Aluminum Square Tube | 1.000" × 1.000" | 0.125" |

| 1.000" × 1.000" × 0.188" 6063 Aluminum Square Tube | 1.000" × 1.000" | 0.188" |

| 1.000" × 1.000" × 0.250" 6063 Aluminum Square Tube | 1.000" × 1.000" | 0.250" |

| 1.500" × 1.500" × 0.065" 6063 Aluminum Square Tube | 1.500" × 1.500" | 0.065" |

| 1.500" × 1.500" × 0.095" 6063 Aluminum Square Tube | 1.500" × 1.500" | 0.095" |

| 1.500" × 1.500" × 0.125" 6063 Aluminum Square Tube | 1.500" × 1.500" | 0.125" |

| 1.500" × 1.500" × 0.188" 6063 Aluminum Square Tube | 1.500" × 1.500" | 0.188" |

| 1.500" × 1.500" × 0.250" 6063 Aluminum Square Tube | 1.500" × 1.500" | 0.250" |

| 2.000" × 2.000" × 0.065" 6063 Aluminum Square Tube | 2.000" × 2.000" | 0.065" |

| 2.000" × 2.000" × 0.095" 6063 Aluminum Square Tube | 2.000" × 2.000" | 0.095" |

| 2.000" × 2.000" × 0.125" 6063 Aluminum Square Tube | 2.000" × 2.000" | 0.125" |

| 2.000" × 2.000" × 0.188" 6063 Aluminum Square Tube | 2.000" × 2.000" | 0.188" |

| 2.000" × 2.000" × 0.250" 6063 Aluminum Square Tube | 2.000" × 2.000" | 0.250" |

| 2.250" × 2.250" × 0.065" 6063 Aluminum Square Tube | 2.250" × 2.250" | 0.065" |

| 2.250" × 2.250" × 0.095" 6063 Aluminum Square Tube | 2.250" × 2.250" | 0.095" |

| 2.500" × 2.500" × 0.125" 6063 Aluminum Square Tube | 2.500" × 2.500" | 0.125" |

| 2.500" × 2.500" × 0.188" 6063 Aluminum Square Tube | 2.500" × 2.500" | 0.188" |

| 2.500" × 2.500" × 0.250" 6063 Aluminum Square Tube | 2.500" × 2.500" | 0.250" |

| 3.000" × 3.000" × 0.065" 6063 Aluminum Square Tube | 3.000" × 3.000" | 0.065" |

| 3.000" × 3.000" × 0.095" 6063 Aluminum Square Tube | 3.000" × 3.000" | 0.095" |

| 3.000" × 3.000" × 0.125" 6063 Aluminum Square Tube | 3.000" × 3.000" | 0.125" |

| 3.000" × 3.000" × 0.188" 6063 Aluminum Square Tube | 3.000" × 3.000" | 0.188" |

| 3.000" × 3.000" × 0.250" 6063 Aluminum Square Tube | 3.000" × 3.000" | 0.250" |

6063 T52 Aluminum Rectangular Tube Sizes

| Description | Width × Height | Wall Thickness |

| 1.000" × 0.500" × 0.095" 6063 T52 Aluminum Rectangular Tube | 1.000" × 0.500" | 0.095" |

| 1.000" × 0.500" × 0.125" 6063 T52 Aluminum Rectangular Tube | 1.000" × 0.500" | 0.125" |

| 2.500" × 1.500" × 0.125" 6063 T52 Aluminum Rectangular Tube | 2.500" × 1.500" | 0.125" |

| 3.000" × 1.000" × 0.065" 6063 T52 Aluminum Rectangular Tube | 3.000" × 1.000" | 0.065" |

| 3.000" × 1.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 3.000" × 1.000" | 0.125" |

| 3.000" × 1.500" × 0.125" 6063 T52 Aluminum Rectangular Tube | 3.000" × 1.500" | 0.125" |

| 3.000" × 1.750" × 0.125" 6063 T52 Aluminum Rectangular Tube | 3.000" × 1.750" | 0.125" |

| 3.000" × 2.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 3.000" × 2.000" | 0.125" |

| 3.000" × 2.000" × 0.250" 6063 T52 Aluminum Rectangular Tube | 3.000" × 2.000" | 0.250" |

| 3.500" × 1.750" × 0.125" 6063 T52 Aluminum Rectangular Tube | 3.500" × 1.750" | 0.125" |

| 4.000" × 1.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 4.000" × 1.000" | 0.125" |

| 4.000" × 1.500" × 0.125" 6063 T52 Aluminum Rectangular Tube | 4.000" × 1.500" | 0.125" |

| 4.000" × 1.750" × 0.125" 6063 T52 Aluminum Rectangular Tube | 4.000" × 1.750" | 0.125" |

| 4.000" × 2.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 4.000" × 2.000" | 0.125" |

| 4.000" × 2.000" × 0.188" 6063 T52 Aluminum Rectangular Tube | 4.000" × 2.000" | 0.188" |

| 4.000" × 2.000" × 0.250" 6063 T52 Aluminum Rectangular Tube | 4.000" × 2.000" | 0.250" |

| 4.000" × 3.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 4.000" × 3.000" | 0.125" |

| 5.000" × 1.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 5.000" × 1.000" | 0.125" |

| 5.000" × 2.000" × 0.125" 6063 T52 Aluminum Rectangular Tube | 5.000" × 2.000" | 0.125" |

6063 T6 Schedule 40 Pipe Sizes

| Description | Nominal Size | Outside Dia. (O.D.) | Inside Dia. (I.D.) | Wall Thickness |

| 1/8" 6063 T6 Schedule 40 Pipe | 1/8" | 0.405" | 0.269" | 0.068" |

| 1/4" 6063 T6 Schedule 40 Pipe | 1/4" | 0.540" | 0.364" | 0.088" |

| 3/8" 6063 T6 Schedule 40 Pipe | 3/8" | 0.675" | 0.493" | 0.091" |

| 1/2" 6063 T6 Schedule 40 Pipe | 1/2" | 0.840" | 0.622" | 0.109" |

| 3/4" 6063 T6 Schedule 40 Pipe | 3/4" | 1.050" | 0.824" | 0.113" |

| 1" 6063 T6 Schedule 40 Pipe | 1" | 1.315" | 1.049" | 0.133" |

| 1¼" 6063 T6 Schedule 40 Pipe | 1¼" | 1.660" | 1.380" | 0.140" |

| 1½" 6063 T6 Schedule 40 Pipe | 1½" | 1.900" | 1.610" | 0.145" |

| 2" 6063 T6 Schedule 40 Pipe | 2" | 2.375" | 2.067" | 0.154" |

| 2½" 6063 T6 Schedule 40 Pipe | 2½" | 2.875" | 2.469" | 0.203" |

| 3" 6063 T6 Schedule 40 Pipe | 3" | 3.500" | 3.068" | 0.216" |

| 3½" 6063 T6 Schedule 40 Pipe | 3½" | 4.000" | 3.548" | 0.226" |

| 4" 6063 T6 Schedule 40 Pipe | 4" | 4.500" | 4.026" | 0.237" |

| 5" 6063 T6 Schedule 40 Pipe | 5" | 5.563" | 5.047" | 0.258" |

| 6" 6063 T6 Schedule 40 Pipe | 6" | 6.625" | 6.065" | 0.280" |

| 8" 6063 T6 Schedule 40 Pipe | 8" | 8.625" | 7.981" | 0.322" |

| 10" 6063 T6 Schedule 40 Pipe | 10" | 10.750" | 10.020" | 0.365" |

| 12" 6063 T6 Schedule 40 Pipe | 12" | 12.750" | 12.000" | 0.375" |

6063 Aluminum Tube Core Properties

| Property Category | Specific Description |

| Corrosion Resistance | The surface easily forms a dense oxide film (Al₂O₃), offering good natural corrosion resistance. Anodizing further enhances its weather resistance, making it suitable for humid or corrosive environments such as marine, chemical, and building exterior walls. |

| Processability | Excellent thermoplasticity, ideal for high-speed extrusion forming. Especially suitable for manufacturing thin-walled, hollow, or complex cross-section profiles. Compatible with various forming processes such as forging, rolling, and cold stamping, offering strong adaptability. |

| Weldability | Excellent welding performance. No stress corrosion cracking after welding. Suitable for multiple welding methods (e.g., TIG, MIG), offering stable and reliable performance in structural connections. |

| Surface Treatment | Capable of high-quality anodizing with uniform color and good decorative appeal. Also compatible with electroplating or spraying, widely used in building decoration, doors and windows, curtain walls, furniture, and other fields with high aesthetic requirements. |

6063 Aluminum Tube Chemical Composition

Alloy Composition: 6063 aluminum belongs to the 6000 series, primarily alloyed with magnesium (0.45–0.9%) and silicon (0.2–0.6%) to enhance strength and heat treatment performance. Trace elements such as chromium, copper, and zinc are kept very low to maintain corrosion resistance.

- Silicon (Si): 0.20 – 0.60 %

- Magnesium (Mg): 0.45 – 0.90 %

- Iron (Fe): ≤ 0.35 %

- Copper (Cu), Zinc (Zn), Chromium (Cr), Titanium (Ti): each ≤ 0.10 %

- Aluminum (Al): Balance

6063 Aluminum Tube Mechanical Properties

- Tensile Strength: Approx. 27 ksi (186 MPa) in T52 temper, approx. 35 ksi (241 MPa) in T6 temper.

- Yield Strength: Approx. 21 ksi (145 MPa) in T52 temper, approx. 31 ksi (214 MPa) in T6 temper.

- Elongation: 12–18% in T52 temper, indicating moderate ductility.

- Hardness: Brinell hardness ranges from 60 (T52) to 95 (T6).

- Heat Treatment: Commonly treated to T5 (air cooling after extrusion) and T6 (solution heat treated and artificially aged) tempers to improve strength and durability.

| Performance Parameter | Feature Description |

| Tensile Strength | Moderate strength, suitable for lightweight load-bearing structures |

| Yield Strength | High threshold for plastic deformation, good stability |

| Elongation | High toughness, excellent impact resistance |

| Density | Lightweight, about 1/3 the weight of steel |

| Thermal and Electrical Conductivity | Suitable for heat dissipation components and conductive elements |

6063 Aluminum Tube Physical Properties

- Density: 2.7 g/cm³ (0.097 lb/in³)

- Melting Range: 610–650 °C (1, 140–1, 210 °F)

- Thermal Expansion Coefficient (20–100 °C): ~13 × 10⁻⁶ /°C

6063 Aluminum Tube Characteristics

- Corrosion Resistance: Superior to 6061 aluminum, making it ideal for outdoor and marine environments.

- Formability: Easily extruded into complex shapes with smooth surfaces, suitable for decorative and architectural purposes.

- Weldability and Machinability: Compatible with conventional welding methods (e.g., TIG, MIG) and machining processes, though welding speed is slower compared to 6061 aluminum.

- Anodizing: Excellent anodizing capability enhances aesthetics and surface protection, which is a key feature for architectural and consumer products.

6063 Aluminum Tube Applications

| Application Field | Typical Applications |

| Architecture | Door and window frames (window frames, door frames), curtain wall mullions, handrails/railings, storefronts, elevator guide rails |

| Structural Field | Lightweight frames, trailer chassis, shelves |

| Furniture and Decoration | Table legs, display racks, lighting tubes, signage |

| Conduits and Electrical | Cable trays, busbars |

| Fluid Handling | Agricultural irrigation pipes, industrial cylinder tubes, pneumatic actuators |

| Marine and Automotive | Lightweight structural tubing, marine components, vehicle chassis tubing, railing systems |

| Industrial Equipment | Machine guarding frames, support structures, heat sinks |

| Electronics and Communication | Antennas, RF waveguides |

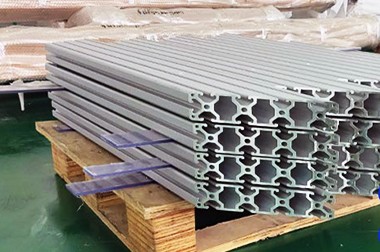

6063 Aluminum Tube Manufacturing and Extrusion

The low extrusion pressure requirement and fine grain structure of 6063 alloy make it a preferred alloy for complex-section tubes. Extruded tubes can be made in round, square, rectangular, oval, elliptical, or custom profiles, with tight dimensional tolerances. The extrusion process allows for continuous lengths, minimal welds, and excellent surface finish.

6063 Aluminum Tube Surface Treatment and Finishing

- Anodizing: 6063 alloy can form a uniform decorative anodized layer; commonly used for architectural tubing.

- Powder Coating/Painting: Excellent adhesion and color uniformity.

- Mechanical Polishing/Brushing: Enhances appearance for furniture and decorative applications.

Finishing options take full advantage of the corrosion resistance and aesthetic potential of 6063 alloy.

Comparison Between 6063 Aluminum Tube and 6061 Aluminum

- Strength: 6063 has approximately 50% lower tensile strength than 6061.

- Formability: 6063 is easier to extrude and bend, making it more suitable for complex designs.

- Aesthetic Quality: The smoother surface and superior anodizing quality of 6063 make it ideal for visible applications.

Limitations of 6063 Aluminum Tube

- Lower Strength: Not suitable for high-stress applications such as aerospace or heavy machinery, which prefer 6061 or 7075 alloys.

- Surface Imperfections: Bright finish tubes may have slight scratches, requiring polishing for aesthetic purposes.

6063 aluminum tube is a versatile, corrosion-resistant material optimized for architectural and lightweight structural applications. Its balanced properties in formability, weldability, and appearance make it a mainstream material for industries prioritizing design and durability over extreme strength.

6063 Aluminum Tube Processing and Handling Considerations

- Heat Treatment: T5 temper (artificial aging) balances strength and ductility, while T6 temper (solution treatment + aging) is suitable for higher strength requirements.

- Parking Effect: Immediate aging after quenching is necessary to avoid strength degradation due to room temperature exposure.

- Surface Treatment: Thorough cleaning is required before anodizing to prevent impurities from affecting the coating quality.

Comparison with 6061 Aluminum

- Strength: The tensile strength of 6063 aluminum is approximately 50% lower than that of 6061 aluminum (6061 aluminum is 45 ksi, while 6063 aluminum is 27 ksi).

- Formability: 6063 aluminum is easier to extrude and bend, making it more suitable for complex designs.

- Aesthetics: 6063 aluminum offers a smoother surface finish and superior anodizing quality, making it an ideal choice for visible applications.

Comparison of 6063 Aluminum with Other Aluminum Alloys

| Comparison Item | 6063 Aluminum Tube | 6061 Aluminum Tube | 7075 Aluminum Tube |

| Strength | Moderate | High | Ultra-high |

| Corrosion Resistance | Excellent | Good | Fair (requires surface treatment) |

| Cost | Economical | Moderate | Expensive |

| Typical Applications | Architectural profiles, general-purpose tubing | Aerospace structural components | High-strength aerospace parts |

6063 aluminum tube is a versatile, corrosion-resistant material optimized for architectural and lightweight structural applications. Its balance of formability, weldability, and aesthetics makes it a mainstream material in industries that prioritize design and durability over extreme strength.