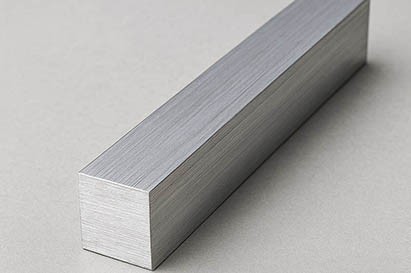

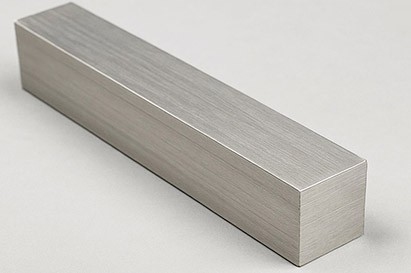

6063 Aluminum Square Tube

6063 aluminum square tube is made from 6063 aluminum alloy through a hot extrusion process to form a square cross-sectional tube.

6063 Aluminum Square Tube offers excellent extrudability, making it suitable for complex cross-sectional forming; it has good weldability, no stress corrosion tendency, and strong surface decorative properties after anodizing.

6063 aluminum square tube is a seamless extruded profile made from 6000 series aluminum alloy (primarily composed of magnesium and silicon), and is available in various tempers (such as T5, T6, T52). It combines medium strength, excellent corrosion resistance, smooth surface finish, and exceptional machinability (including welding, machining, and anodizing), making it the preferred material for architectural, structural, and decorative applications such as window and door frames, furniture components, railings, signage, and lightweight framing systems.

6063 aluminum square tube is directly extruded using square molds, producing sharp 90° corners and a smooth mill finish surface without seams. The most common tempers for this alloy include T5 (artificial aging after cooling), T6 (solution heat treatment followed by artificial aging), and T52 (over-aging to enhance stress corrosion resistance). Each temper balances strength and formability to meet different end-use requirements. Typical specifications for extruded aluminum profiles comply with ASTM B221 standards.

6063 aluminum square tube is a seamless, extruded structural alloy, primarily composed of aluminum (98.9%), with small amounts of magnesium (0.45–0.9%) and silicon (0.2–0.6%) added to enhance formability and corrosion resistance. The T52 temper indicates that stress is relieved through stretching, achieving a balance of medium strength and machinability.

Haomei Aluminum specializes in producing high-quality 6063 aluminum alloy square tubes with excellent corrosion resistance and outstanding processing performance, widely used in architectural decoration, mechanical structures, transportation, and other fields. We support custom length cutting, anodizing, sandblasting, and various other deep processing services to meet all your project needs in one stop.

6063 Aluminum Square Tube Available Sizes and Specifications

- Standard sizes: range from ½ inch × ½ inch to 8 inches × 8 inches,

- Wall thickness from 0.062 inch (1/16 inch) to 0.5 inch.

- Length: commonly stocked in 12 feet to 24 feet, with custom cutting options available.

| Description | Outer diameter size (A × A) | Wall thickness(t) |

| 0.625″ × 0.625″ × 0.050″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.050″ |

| 0.625″ × 0.625″ × 0.065″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.065″ |

| 0.625″ × 0.625″ × 0.095″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.095″ |

| 0.625″ × 0.625″ × 0.125″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.125″ |

| 0.625″ × 0.625″ × 0.120″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.120″ |

| 0.625″ × 0.625″ × 0.188″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.188″ |

| 0.625″ × 0.625″ × 0.250″ 6063 Aluminum Square Tube | 0.625″ × 0.625″ | 0.250″ |

| 0.750″ × 0.750″ × 0.050″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.050″ |

| 0.750″ × 0.750″ × 0.065″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.065″ |

| 0.750″ × 0.750″ × 0.095″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.095″ |

| 0.750″ × 0.750″ × 0.125″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.125″ |

| 0.750″ × 0.750″ × 0.120″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.120″ |

| 0.750″ × 0.750″ × 0.188″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.188″ |

| 0.750″ × 0.750″ × 0.250″ 6063 Aluminum Square Tube | 0.750″ × 0.750″ | 0.250″ |

| 1.000″ × 1.000″ × 0.050″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.050″ |

| 1.000″ × 1.000″ × 0.065″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.065″ |

| 1.000″ × 1.000″ × 0.095″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.095″ |

| 1.000″ × 1.000″ × 0.125″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.125″ |

| 1.000″ × 1.000″ × 0.120″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.120″ |

| 1.000″ × 1.000″ × 0.188″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.188″ |

| 1.000″ × 1.000″ × 0.250″ 6063 Aluminum Square Tube | 1.000″ × 1.000″ | 0.250″ |

| 1.250″ × 1.250″ × 0.050″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.050″ |

| 1.250″ × 1.250″ × 0.065″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.065″ |

| 1.250″ × 1.250″ × 0.095″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.095″ |

| 1.250″ × 1.250″ × 0.125″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.125″ |

| 1.250″ × 1.250″ × 0.120″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.120″ |

| 1.250″ × 1.250″ × 0.188″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.188″ |

| 1.250″ × 1.250″ × 0.250″ 6063 Aluminum Square Tube | 1.250″ × 1.250″ | 0.250″ |

| 1.500″ × 1.500″ × 0.050″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.050″ |

| 1.500″ × 1.500″ × 0.065″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.065″ |

| 1.500″ × 1.500″ × 0.095″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.095″ |

| 1.500″ × 1.500″ × 0.125″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.125″ |

| 1.500″ × 1.500″ × 0.120″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.120″ |

| 1.500″ × 1.500″ × 0.188″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.188″ |

| 1.500″ × 1.500″ × 0.250″ 6063 Aluminum Square Tube | 1.500″ × 1.500″ | 0.250″ |

| 1.750″ × 1.750″ × 0.050″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.050″ |

| 1.750″ × 1.750″ × 0.065″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.065″ |

| 1.750″ × 1.750″ × 0.095″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.095″ |

| 1.750″ × 1.750″ × 0.125″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.125″ |

| 1.750″ × 1.750″ × 0.120″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.120″ |

| 1.750″ × 1.750″ × 0.188″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.188″ |

| 1.750″ × 1.750″ × 0.250″ 6063 Aluminum Square Tube | 1.750″ × 1.750″ | 0.250″ |

| 2.000″ × 2.000″ × 0.050″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.050″ |

| 2.000″ × 2.000″ × 0.065″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.065″ |

| 2.000″ × 2.000″ × 0.095″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.095″ |

| 2.000″ × 2.000″ × 0.125″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.125″ |

| 2.000″ × 2.000″ × 0.120″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.120″ |

| 2.000″ × 2.000″ × 0.188″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.188″ |

| 2.000″ × 2.000″ × 0.250″ 6063 Aluminum Square Tube | 2.000″ × 2.000″ | 0.250″ |

| 2.250″ × 2.250″ × 0.050″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.050″ |

| 2.250″ × 2.250″ × 0.065″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.065″ |

| 2.250″ × 2.250″ × 0.095″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.095″ |

| 2.250″ × 2.250″ × 0.125″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.125″ |

| 2.250″ × 2.250″ × 0.120″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.120″ |

| 2.250″ × 2.250″ × 0.188″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.188″ |

| 2.250″ × 2.250″ × 0.250″ 6063 Aluminum Square Tube | 2.250″ × 2.250″ | 0.250″ |

| 2.500″ × 2.500″ × 0.050″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.050″ |

| 2.500″ × 2.500″ × 0.065″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.065″ |

| 2.500″ × 2.500″ × 0.095″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.095″ |

| 2.500″ × 2.500″ × 0.125″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.125″ |

| 2.500″ × 2.500″ × 0.120″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.120″ |

| 2.500″ × 2.500″ × 0.188″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.188″ |

| 2.500″ × 2.500″ × 0.250″ 6063 Aluminum Square Tube | 2.500″ × 2.500″ | 0.250″ |

| 3.000″ × 3.000″ × 0.050″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.050″ |

| 3.000″ × 3.000″ × 0.065″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.065″ |

| 3.000″ × 3.000″ × 0.095″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.095″ |

| 3.000″ × 3.000″ × 0.125″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.125″ |

| 3.000″ × 3.000″ × 0.120″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.120″ |

| 3.000″ × 3.000″ × 0.188″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.188″ |

| 3.000″ × 3.000″ × 0.250″ 6063 Aluminum Square Tube | 3.000″ × 3.000″ | 0.250″ |

| 3.500″ × 3.500″ × 0.050″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.050″ |

| 3.500″ × 3.500″ × 0.065″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.065″ |

| 3.500″ × 3.500″ × 0.095″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.095″ |

| 3.500″ × 3.500″ × 0.125″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.125″ |

| 3.500″ × 3.500″ × 0.120″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.120″ |

| 3.500″ × 3.500″ × 0.188″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.188″ |

| 3.500″ × 3.500″ × 0.250″ 6063 Aluminum Square Tube | 3.500″ × 3.500″ | 0.250″ |

| 4.000″ × 4.000″ × 0.050″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.050″ |

| 4.000″ × 4.000″ × 0.065″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.065″ |

| 4.000″ × 4.000″ × 0.095″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.095″ |

| 4.000″ × 4.000″ × 0.125″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.125″ |

| 4.000″ × 4.000″ × 0.120″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.120″ |

| 4.000″ × 4.000″ × 0.188″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.188″ |

| 4.000″ × 4.000″ × 0.250″ 6063 Aluminum Square Tube | 4.000″ × 4.000″ | 0.250″ |

6063 Aluminum Square Tube Chemical Composition and Standards

The nominal composition of 6063 alloy includes 0.45–0.90% magnesium and 0.20–0.60% silicon, with the remainder being aluminum (97.5–99.35%), as well as trace amounts of iron, copper, manganese, chromium, titanium, zinc, and other elements (each ≤0.10%). This composition complies with the Aluminum Association standard AA 6063 (commonly referred to as A6063), and is governed by ASTM and ISO extrusion standards such as EN 755-2 and ISO 6361.

6063 Aluminum Square Tube Mechanical Properties

- 6063-O (annealed condition): Tensile strength ≤ 19 ksi, elongation 18%.

- 6063-T5: Tensile strength ≥ 20 ksi (0.5 inch or less) to 19 ksi (> 0.5 inch), yield strength ≥ 14 ksi / 13 ksi, elongation ~8%.

- 6063-T6: Tensile strength ≥ 28 ksi, yield strength ≥ 23 ksi, elongation 8 – 10%, depending on section thickness.

We also produce other tempers (T52, T53, T54, T832) to meet specific requirements for corrosion resistance, conductivity, and surface finish.

6063 Aluminum Square Tube Corrosion Resistance

Naturally forms an aluminum oxide film on the surface, providing excellent corrosion resistance.

Corrosion resistance can be further enhanced through anodizing and coating treatments, showing stable performance especially in marine environments.

6063 Aluminum Square Tube Characteristics

- Corrosion resistance: Demonstrates excellent corrosion resistance in industrial, marine, and atmospheric environments, superior to many other alloys such as 6061. Performs well in oxidation-prone or humid conditions, making it suitable for construction and marine applications.

- Formability and machinability: Highly suitable for bending, stamping, drilling, and machining operations; easier to form than high-strength alloys.

- Weldability: Exhibits excellent compatibility with TIG, MIG, and resistance welding; strength can be restored through heat treatment after welding.

- Surface finish: Rolled surface is smooth and free of die lines, suitable for anodizing or powder coating; anodized surface provides a durable decorative finish with color options, including transparent or custom colors.

- Lightweight: With a density of 0.1 lb/in³ (2.7 g/cm³), it is ideal for applications requiring weight reduction.

- Attractive surface: Smooth surface, sharp edges, 90° corners; commonly used in decorative applications or anodized for enhanced appearance.

6063 Aluminum Square Tube Applications

6063 aluminum square tube has moderate strength, lightweight (density ≈ 2.69 g/cm³), and attractive surface finish, making it ideal for the following applications:

- Architectural manufacturing: Door and window frames, curtain walls, roofing decorations, railings, and storefronts.

- Decorative: Handrails, sign frames, furniture components, lighting fixtures, fences, decorative components with colored wood grain surface treatment, and display racks.

- Structural and lightweight framing systems: Trailer frames, shelving brackets, medium-load-bearing structures, and modular frames.

- Electromechanical: Conduits, cable trays, rack brackets, and equipment enclosures in HVAC, electrical, and low-stress mechanical components.

- Industrial fields: Vehicle chassis, irrigation pipes, communication facilities (such as waveguides and antennas).

6063 Aluminum Square Tube Manufacturing Process

Produced using hot extrusion, combined with die design to produce square tubes of various large diameters. High-quality manufacturers ensure straightness and mechanical properties through processes such as online quenching and stretch straightening.

Surface treatment and secondary processing

6063 square tubes are easy to perform common secondary processes to enhance performance or appearance:

- Anodizing: Type II sulfuric acid anodizing (in accordance with MIL-A-8625 standard) forms a uniform oxide layer with corrosion resistance and dye absorption; Type III (hard anodizing) is used in applications requiring wear resistance.

- Powder coating and painting: Provides durable colored surfaces for decorative or protective purposes, usually applied over a chromate conversion primer.

- Machining and fabrication: CNC cutting, milling, drilling, and bending operations enable tight tolerances; post-fabrication heat treatment can restore strength lost during welding or machining.

6063 aluminum square tube is a versatile extruded profile that balances formability, surface quality, and moderate strength. Its excellent portability and environmental resistance make it a primary material in construction, industrial, and decorative fields.

6063 Aluminum Square Tube Considerations

- Temper selection: T5 (natural aging) is suitable for general structures, while T6 (artificial aging) is used in high-strength applications.

- Processing limitations: Age hardening should be performed promptly after quenching to avoid "parking effect" that reduces strength.

Comparison with 6061 Aluminum

While 6063 aluminum is favored for its formability and surface finish, 6061 aluminum offers higher strength (tensile strength: 45 ksi vs. 27 ksi), making it more suitable for heavy-duty structural applications.

Purchasing Considerations

- Standard: Conforms to ASTM B221 specification.

- Surface finish: Rolled surface (non-polished) may have surface scratches.