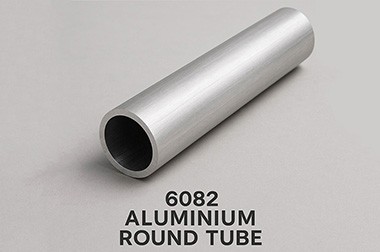

6063 Aluminum Round Tube

The 6063 aluminum round tube is a circular tube made of 6063 aluminum alloy, which belongs to the Al-Mg-Si alloy series. Compared with other materials, the 6063 aluminum round tube stands out in weight, weather resistance, and cost-effectiveness, making it especially suitable for scenarios that require frequent processing or exposure to corrosive environments.

6063 aluminum round tube is a widely used extruded product known for its excellent combination of strength, formability, and corrosion resistance.

The 6063 aluminum round tube is an extruded product made from 6063 alloy. 6063 is a medium-strength, heat-treatable magnesium-silicon aluminum alloy known for its excellent corrosion resistance, high surface finish, and superior anodizing characteristics. After tempering treatment (most commonly T5 or T6), it is widely produced in accordance with ASTM B221 / AMS QQ-A-200/8 standards and specified for the European market according to BS EN 573-3.

As a leading manufacturer of 6063 aluminum round tubes, Haomei Aluminum focuses on producing high-quality, corrosion-resistant tubing for applications in construction, automotive, HVAC, and industrial uses. Our 6063 aluminum tubes are precisely machined, offering excellent weldability, machinability, and structural integrity, meeting ASTM B221 and EN 755 standards. We provide custom sizes (outer diameter from 5 mm to 250 mm), wall thicknesses, and surface finishes (anodizing, powder coating, mill finish). You can enjoy highly competitive pricing, volume order discounts, and fast global delivery. Our ISO-certified production process ensures consistent quality and environmentally friendly manufacturing practices you can trust. Contact us for customized solutions and technical support!

6063 Aluminum Round Tube Chemical Composition and Alloy Characteristics

Alloying Elements

- Magnesium (Mg): 0.45–0.90 wt % – Enhances strength through precipitation hardening

- Silicon (Si): 0.20–0.60 wt % – Lowers melting temperature and improves extrusion fluidity

- Trace elements: Iron ≤ 0.35 wt %, Chromium/Copper/Manganese/Titanium/Zinc each ≤ 0.10 wt %, other elements combined ≤ 0.15 wt %

- Aluminum (Al): Remainder (~97.5–99.35 wt %)

6063 Aluminum Round Tube Physical and Mechanical Properties

Key Physical Data

- Density: 2.69 g/cm³

- Thermal Conductivity: 201–218 W/m·K

- Coefficient of Thermal Expansion: 23.4 µm/m·K

- Specific Heat: 900 J/kg·K

6063 Aluminum Round Tube Mechanical Properties by Temper

- T5: Tensile Strength ≥ 20, 000 psi; Yield Strength ≥ 14, 000 psi; Elongation ~8%

- T6: Tensile Strength ≥ 28, 000 psi; Yield Strength ≥ 23, 000 psi; Elongation 8–10%

- Other tempers: O, T1, T4, T52, etc., tailored for specific strength/ductility trade-offs

6063 Aluminum Round Tube Temper Options

- T5: Air-cooled after extrusion and artificially aged (common for structural uses).

- T6: Solution heat-treated and artificially aged, offering higher strength (ultimate tensile strength: ~241 MPa, yield strength: ~214 MPa).

- T832: Cold-worked and artificially aged for the highest strength among 6063 variants

Haomei 6063 Aluminum Round Tube Supply

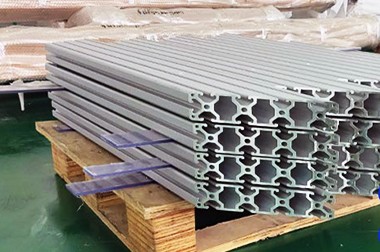

- Extrusion Process: Easily formed into complex cross-sections, making it the most commonly extruded aluminum alloy

- Dimensions: Diameter ranges from ½ inch to 4 inches (12.7 mm to 101.6 mm), with wall thickness up to 0.5 inch (12.7 mm)

- Surface Finish: Typically anodized to enhance corrosion resistance and appearance

| Description | Outer diameter | Wall thickness |

| 3/8" × 0.035" 6063 Aluminum Round Tube | 0.375" | 0.035" |

| 3/8" × 0.049" 6063 Aluminum Round Tube | 0.375" | 0.049" |

| 3/8" × 0.065" 6063 Aluminum Round Tube | 0.375" | 0.065" |

| 3/8" × 0.083" 6063 Aluminum Round Tube | 0.375" | 0.083" |

| 3/8" × 0.095" 6063 Aluminum Round Tube | 0.375" | 0.095" |

| 3/8" × 0.109" 6063 Aluminum Round Tube | 0.375" | 0.109" |

| 3/8" × 0.134" 6063 Aluminum Round Tube | 0.375" | 0.134" |

| 3/8" × 0.188" 6063 Aluminum Round Tube | 0.375" | 0.188" |

| 1/2" × 0.035" 6063 Aluminum Round Tube | 0.500" | 0.035" |

| 1/2" × 0.049" 6063 Aluminum Round Tube | 0.500" | 0.049" |

| 1/2" × 0.065" 6063 Aluminum Round Tube | 0.500" | 0.065" |

| 1/2" × 0.083" 6063 Aluminum Round Tube | 0.500" | 0.083" |

| 1/2" × 0.095" 6063 Aluminum Round Tube | 0.500" | 0.095" |

| 1/2" × 0.109" 6063 Aluminum Round Tube | 0.500" | 0.109" |

| 1/2" × 0.134" 6063 Aluminum Round Tube | 0.500" | 0.134" |

| 1/2" × 0.188" 6063 Aluminum Round Tube | 0.500" | 0.188" |

| 5/8" × 0.035" 6063 Aluminum Round Tube | 0.625" | 0.035" |

| 5/8" × 0.049" 6063 Aluminum Round Tube | 0.625" | 0.049" |

| 5/8" × 0.065" 6063 Aluminum Round Tube | 0.625" | 0.065" |

| 5/8" × 0.083" 6063 Aluminum Round Tube | 0.625" | 0.083" |

| 5/8" × 0.095" 6063 Aluminum Round Tube | 0.625" | 0.095" |

| 5/8" × 0.109" 6063 Aluminum Round Tube | 0.625" | 0.109" |

| 5/8" × 0.134" 6063 Aluminum Round Tube | 0.625" | 0.134" |

| 5/8" × 0.188" 6063 Aluminum Round Tube | 0.625" | 0.188" |

| 3/4" × 0.035" 6063 Aluminum Round Tube | 0.750" | 0.035" |

| 3/4" × 0.049" 6063 Aluminum Round Tube | 0.750" | 0.049" |

| 3/4" × 0.065" 6063 Aluminum Round Tube | 0.750" | 0.065" |

| 3/4" × 0.083" 6063 Aluminum Round Tube | 0.750" | 0.083" |

| 3/4" × 0.095" 6063 Aluminum Round Tube | 0.750" | 0.095" |

| 3/4" × 0.109" 6063 Aluminum Round Tube | 0.750" | 0.109" |

| 3/4" × 0.134" 6063 Aluminum Round Tube | 0.750" | 0.134" |

| 3/4" × 0.188" 6063 Aluminum Round Tube | 0.750" | 0.188" |

| 7/8" × 0.035" 6063 Aluminum Round Tube | 0.875" | 0.035" |

| 7/8" × 0.049" 6063 Aluminum Round Tube | 0.875" | 0.049" |

| 7/8" × 0.065" 6063 Aluminum Round Tube | 0.875" | 0.065" |

| 7/8" × 0.083" 6063 Aluminum Round Tube | 0.875" | 0.083" |

| 7/8" × 0.095" 6063 Aluminum Round Tube | 0.875" | 0.095" |

| 7/8" × 0.109" 6063 Aluminum Round Tube | 0.875" | 0.109" |

| 7/8" × 0.134" 6063 Aluminum Round Tube | 0.875" | 0.134" |

| 7/8" × 0.188" 6063 Aluminum Round Tube | 0.875" | 0.188" |

| 1" × 0.035" 6063 Aluminum Round Tube | 1.000" | 0.035" |

| 1" × 0.049" 6063 Aluminum Round Tube | 1.000" | 0.049" |

| 1" × 0.065" 6063 Aluminum Round Tube | 1.000" | 0.065" |

| 1" × 0.083" 6063 Aluminum Round Tube | 1.000" | 0.083" |

| 1" × 0.095" 6063 Aluminum Round Tube | 1.000" | 0.095" |

| 1" × 0.109" 6063 Aluminum Round Tube | 1.000" | 0.109" |

| 1" × 0.134" 6063 Aluminum Round Tube | 1.000" | 0.134" |

| 1" × 0.188" 6063 Aluminum Round Tube | 1.000" | 0.188" |

| 1 1/4" × 0.035" 6063 Aluminum Round Tube | 1.250" | 0.035" |

| 1 1/4" × 0.049" 6063 Aluminum Round Tube | 1.250" | 0.049" |

| 1 1/4" × 0.065" 6063 Aluminum Round Tube | 1.250" | 0.065" |

| 1 1/4" × 0.083" 6063 Aluminum Round Tube | 1.250" | 0.083" |

| 1 1/4" × 0.095" 6063 Aluminum Round Tube | 1.250" | 0.095" |

| 1 1/4" × 0.109" 6063 Aluminum Round Tube | 1.250" | 0.109" |

| 1 1/4" × 0.134" 6063 Aluminum Round Tube | 1.250" | 0.134" |

| 1 1/4" × 0.188" 6063 Aluminum Round Tube | 1.250" | 0.188" |

| 1 1/2" × 0.035" 6063 Aluminum Round Tube | 1.500" | 0.035" |

| 1 1/2" × 0.049" 6063 Aluminum Round Tube | 1.500" | 0.049" |

| 1 1/2" × 0.065" 6063 Aluminum Round Tube | 1.500" | 0.065" |

| 1 1/2" × 0.083" 6063 Aluminum Round Tube | 1.500" | 0.083" |

| 1 1/2" × 0.095" 6063 Aluminum Round Tube | 1.500" | 0.095" |

| 1 1/2" × 0.109" 6063 Aluminum Round Tube | 1.500" | 0.109" |

| 1 1/2" × 0.134" 6063 Aluminum Round Tube | 1.500" | 0.134" |

| 1 1/2" × 0.188" 6063 Aluminum Round Tube | 1.500" | 0.188" |

| 2" × 0.035" 6063 Aluminum Round Tube | 2.000" | 0.035" |

| 2" × 0.049" 6063 Aluminum Round Tube | 2.000" | 0.049" |

| 2" × 0.065" 6063 Aluminum Round Tube | 2.000" | 0.065" |

| 2" × 0.083" 6063 Aluminum Round Tube | 2.000" | 0.083" |

| 2" × 0.095" 6063 Aluminum Round Tube | 2.000" | 0.095" |

| 2" × 0.109" 6063 Aluminum Round Tube | 2.000" | 0.109" |

| 2" × 0.134" 6063 Aluminum Round Tube | 2.000" | 0.134" |

| 2" × 0.188" 6063 Aluminum Round Tube | 2.000" | 0.188" |

| 2 1/2" × 0.035" 6063 Aluminum Round Tube | 2.500" | 0.035" |

| 2 1/2" × 0.049" 6063 Aluminum Round Tube | 2.500" | 0.049" |

| 2 1/2" × 0.065" 6063 Aluminum Round Tube | 2.500" | 0.065" |

| 2 1/2" × 0.083" 6063 Aluminum Round Tube | 2.500" | 0.083" |

| 2 1/2" × 0.095" 6063 Aluminum Round Tube | 2.500" | 0.095" |

| 2 1/2" × 0.109" 6063 Aluminum Round Tube | 2.500" | 0.109" |

| 2 1/2" × 0.134" 6063 Aluminum Round Tube | 2.500" | 0.134" |

| 2 1/2" × 0.188" 6063 Aluminum Round Tube | 2.500" | 0.188" |

| 3" × 0.035" 6063 Aluminum Round Tube | 3.000" | 0.035" |

| 3" × 0.049" 6063 Aluminum Round Tube | 3.000" | 0.049" |

| 3" × 0.065" 6063 Aluminum Round Tube | 3.000" | 0.065" |

| 3" × 0.083" 6063 Aluminum Round Tube | 3.000" | 0.083" |

| 3" × 0.095" 6063 Aluminum Round Tube | 3.000" | 0.095" |

| 3" × 0.109" 6063 Aluminum Round Tube | 3.000" | 0.109" |

| 3" × 0.134" 6063 Aluminum Round Tube | 3.000" | 0.134" |

| 3" × 0.188" 6063 Aluminum Round Tube | 3.000" | 0.188" |

| 3 1/2" × 0.035" 6063 Aluminum Round Tube | 3.500" | 0.035" |

| 3 1/2" × 0.049" 6063 Aluminum Round Tube | 3.500" | 0.049" |

| 3 1/2" × 0.065" 6063 Aluminum Round Tube | 3.500" | 0.065" |

| 3 1/2" × 0.083" 6063 Aluminum Round Tube | 3.500" | 0.083" |

| 3 1/2" × 0.095" 6063 Aluminum Round Tube | 3.500" | 0.095" |

| 3 1/2" × 0.109" 6063 Aluminum Round Tube | 3.500" | 0.109" |

| 3 1/2" × 0.134" 6063 Aluminum Round Tube | 3.500" | 0.134" |

| 3 1/2" × 0.188" 6063 Aluminum Round Tube | 3.500" | 0.188" |

| 4" × 0.035" 6063 Aluminum Round Tube | 4.000" | 0.035" |

| 4" × 0.049" 6063 Aluminum Round Tube | 4.000" | 0.049" |

| 4" × 0.065" 6063 Aluminum Round Tube | 4.000" | 0.065" |

| 4" × 0.083" 6063 Aluminum Round Tube | 4.000" | 0.083" |

| 4" × 0.095" 6063 Aluminum Round Tube | 4.000" | 0.095" |

| 4" × 0.109" 6063 Aluminum Round Tube | 4.000" | 0.109" |

| 4" × 0.134" 6063 Aluminum Round Tube | 4.000" | 0.134" |

| 4" × 0.188" 6063 Aluminum Round Tube | 4.000" | 0.188" |

| 5" × 0.035" 6063 Aluminum Round Tube | 5.000" | 0.035" |

| 5" × 0.049" 6063 Aluminum Round Tube | 5.000" | 0.049" |

| 5" × 0.065" 6063 Aluminum Round Tube | 5.000" | 0.065" |

| 5" × 0.083" 6063 Aluminum Round Tube | 5.000" | 0.083" |

| 5" × 0.095" 6063 Aluminum Round Tube | 5.000" | 0.095" |

| 5" × 0.109" 6063 Aluminum Round Tube | 5.000" | 0.109" |

| 5" × 0.134" 6063 Aluminum Round Tube | 5.000" | 0.134" |

| 5" × 0.188" 6063 Aluminum Round Tube | 5.000" | 0.188" |

6063 Aluminum Round Tube Manufacturing and Heat Treatment

- Extrusion: 6063 is optimized for producing complex extrusions with extremely smooth surfaces.

- Welding: Excellent weldability (TIG/MIG); post-weld strength returns to the 6063-O condition but can be re-aged to restore temper.

- Heat Treatment: Artificial aging (T5) or solution heat treatment plus aging (T6) to achieve peak strength.

6063 Aluminum Round Tube Surface Finishing

- Anodizing: Suitable for clear or colored finishes; 6063's fine grain structure results in a uniform and bright appearance.

- Hard Anodizing: Used for cylinder tubes and wear-resistant applications.

- Powder Coating: Commonly used for architectural handrails, fences, and decorative purposes.

6063 Aluminum Round Tube Machining Advantages

- Excellent formability enables efficient production of complex cross-sections through extrusion; supports secondary processing such as cutting, drilling, and bending to meet custom requirements.

- Combines good thermal and electrical conductivity, making it suitable for heat sinks and electronic components.

6063 Aluminum Round Tube Applications

Construction Field

Preferred material for doors, windows, and curtain wall frames; also used for decorative components, irrigation pipes, and fencing.

Industry and Transportation

Lightweight components for automotive parts, aerospace structural elements, and marine equipment.

Used in mechanical manufacturing for equipment enclosures and support structures.

Electronics and Communication

Used to manufacture antennas, waveguides, heat sinks, etc., relying on its conductivity and machining precision.

- Construction: Door and window frames, curtain walls, signage frames

- Decoration: Furniture, lighting fixtures, decorative tubes

- Machinery: Cylinders, electrical busbars, heat sinks

- Structures: Handrails, fences, posts (especially where surface finish is more important than strength)

- Marine/Transport: Non-critical piping, decorative components, and parts where corrosion resistance is essential

6063 Aluminum Round Tube Advantages and Limitations

6063 Aluminum Round Tube Advantages

- Corrosion Resistance: Superior to 6061 in neutral environments

- Surface Quality: Smooth extruded surface—ideal for anodizing and visible components

- Formability: More ductile than many other alloys—good for bending and flaring

- Weldability: Maintains reasonable strength after welding

- Lightweight: Suitable for weight-sensitive applications.

- Weld Compatibility: Compatible with TIG welding, but post-weld heat treatment may be needed to restore strength.

- Sustainability: Fully recyclable, minimizing material loss.

6063 Aluminum Round Tube Limitations

- Lower Strength: Approximately half the strength of 6061 (T6)—not suitable for high-load structural components

- Temperature Limitation: Not recommended for use above 150°C due to strength degradation

Comparison Between 6063 Aluminum Round Tube and 6061 Aluminum Alloy

- Strength: 6061 aluminum alloy has higher strength (e.g., T6 tensile strength is 310 MPa, while 6063-T6 has a tensile strength of 241 MPa).

- Formability: 6063 aluminum alloy excels in extrusion complexity and surface finish, while 6061 aluminum alloy offers better structural rigidity.

- Corrosion Resistance: Due to its lower copper content, 6063 aluminum alloy performs better than 6061 in corrosive environments.

6063 Aluminum Round Tube Standards and Specifications

- ASTM B221: Wrought 6063 extruded profiles

- AMS QQ-A-200/8: Quality assurance for materials such as 6063-T6, T52, etc.

- BS EN 573-3: Chemical composition control for European supply

6063 aluminum round tube combines good mechanical properties (especially in T5/T6 temper), excellent surface treatment capability, and corrosion resistance. For any tubing application where appearance, anodizing quality, and moderate strength outweigh the need for maximum load-bearing, it is the alloy of choice for architectural use. The versatility of this alloy, along with compliance with global standards (ASTM B221 / AMS QQ-A-200/8 / BS EN 573-3), ensures consistent quality across various markets.