6063 Aluminum Round Bar

6063 aluminum round bar is a typical representative of Al-Mg-Si series heat-treatable strengthening aluminum alloys, offering excellent machinability and comprehensive mechanical properties.

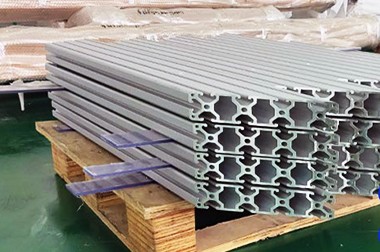

6063 aluminum round bar is a medium-strength alloy, known for its excellent extrudability, good surface finish, and high corrosion resistance, making it an ideal choice for architectural and decorative applications. This alloy is mainly available in T5, T6, and T52 tempers, offering balanced tensile strength and good weldability, with outstanding anodizing and polishing capabilities. Typical applications include structural profiles, piping, heat sinks, and electrical components.

6063 aluminum is renowned for its lightweight, corrosion resistance, and excellent extrudability. Often referred to as a "building alloy" due to its smooth surface, it is ideal for anodizing and decorative uses. Compared with 6061, it has lower strength but superior formability and aesthetics.

6063 aluminum round bars are commonly used in decorative, architectural, and marine applications. Though 6063 aluminum has relatively low strength, it offers excellent corrosion resistance and a smoother surface than other aluminum alloys. 6063 round bars/rods are available in full sizes and custom cut lengths.

6063 Aluminum Round Bar Professional Manufacturer, providing precision-machined alloy bars for aerospace, construction, and automotive industries. Our T6 tempered 6063 aluminum bars feature excellent corrosion resistance, lightweight durability, and customizable dimensions. We are ISO certified, with large inventories and fast global delivery.

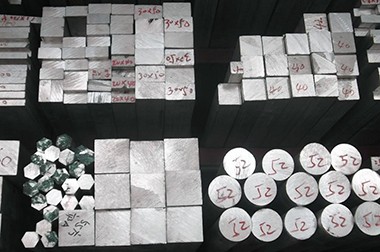

6063 Aluminum Round Bar Standard Sizes and Availability

6063 round bars are stocked in diameters ranging from ¼ inch (6 mm) to several inches, with common lengths from 12 to 144 inches (300–3600 mm). Haomei Aluminum offers custom lengths and small-batch T5, T6, and T52 temper materials, with volume discounts available for bulk orders.

6063 Aluminum Round Bar Dimensions and Availability

| Category | Description |

| Diameter Range | Imperial: 1/8 inch to 10 inches |

| Metric: 3 mm to 300 mm | |

| Standard Length | Extruded Bars: up to 192 inches (approx. 16 feet) |

| Cold Drawn Bars: up to 6 meters (19.7 feet), customizable | |

| Surface Treatment | Standard: Mill finish, polishing, anodizing (silver, black, bronze) |

| Custom: Powder coating, sandblasting, brushing | |

| Tolerance | ±0.002 inch (approx. ±0.005 cm), suitable for precision applications |

| Standards & Certifications | UNS: A96063 |

| ASTM: B221 (extruded), B211 (cold drawn), AMS 4156, AMS QQ-A-200/9 | |

| ISO: AlMg0.5Si | |

| Others: Compatible with EN, DIN, JIS standards | |

| Environmental Certification: RoHS, REACH compliant |

6063 Aluminum Round Bar Stock Sizes

| Description | Inches (in) | Metric equivalents (mm) |

| 1/8" 6063 Aluminum Round Bar | 1/8" | 3.18 mm |

| 1/4" 6063 Aluminum Round Bar | 1/4" | 6.35 mm |

| 3/8" 6063 Aluminum Round Bar | 3/8" | 9.53 mm |

| 1/2" 6063 Aluminum Round Bar | 1/2" | 12.70 mm |

| 5/8" 6063 Aluminum Round Bar | 5/8" | 15.88 mm |

| 3/4" 6063 Aluminum Round Bar | 3/4" | 19.05 mm |

| 7/8" 6063 Aluminum Round Bar | 7/8" | 22.23 mm |

| 1" 6063 Aluminum Round Bar | 1" | 25.40 mm |

| 1-1/4" 6063 Aluminum Round Bar | 1-1/4" | 31.75 mm |

| 1-1/2" 6063 Aluminum Round Bar | 1-1/2" | 38.10 mm |

| 2" 6063 Aluminum Round Bar | 2" | 50.80 mm |

| 2-1/2" 6063 Aluminum Round Bar | 2-1/2" | 63.50 mm |

| 3" 6063 Aluminum Round Bar | 3" | 76.20 mm |

| 4" 6063 Aluminum Round Bar | 4" | 101.60 mm |

| 5" 6063 Aluminum Round Bar | 5" | 127.00 mm |

| 6" 6063 Aluminum Round Bar | 6" | 152.40 mm |

| 8" 6063 Aluminum Round Bar | 8" | 203.20 mm |

| 10" 6063 Aluminum Round Bar | 10" | 254.00 mm |

6063 Aluminum Round Bar Chemical Composition

The nominal composition of 6063 alloy is primarily aluminum (remainder), with the main alloying elements as follows: 0.45–0.90% magnesium, 0.20–0.60% silicon, and trace amounts of chromium, iron, copper, manganese, titanium, and zinc (each element ≤0.10%). The controlled Mg-Si ratio forms Mg₂Si precipitates during the aging process, providing a unique combination of strength and formability.

| Element | Percentage |

| Mg | 0.45–0.9% |

| Si | 0.2–0.6% |

| Fe | ≤0.35% |

| Cu | ≤0.1% |

| Cr | ≤0.1% |

| Zn | ≤0.1% |

| Al | Balance (~98.9%) |

6063 Aluminum Round Bar Mechanical Properties

T6 Temper (Solution Heat Treated + Artificial Aging)

- Ultimate Tensile Strength: 190–215 MPa (27.5–31.2 ksi)

- Yield Strength (0.2% offset): 155–160 MPa (22.5–23.2 ksi)

- Elongation at Break: approximately 8–12%

T5/T52 Temper (Extrusion Cooling + Artificial Aging)

- Slightly lower strength than T6, but optimized surface finish and anodizing quality

- Modulus of Elasticity: approximately 68.9 GPa (10, 000 ksi) under tensile and compressive loads

Heat Treatment and Tempers

- O (Annealed): Offers the highest ductility but lowest strength

- T4 (Solution Heat Treated Only): Good formability, suitable for complex extrusions; moderate strength, allows post-forming aging

- T5/T52 (Extruded and Aged): Balanced strength and excellent surface appearance, commonly used for architectural bars and rebar

- T6 (Solution Heat Treated and Artificially Aged): Provides the highest mechanical performance, suitable for moderately stressed components

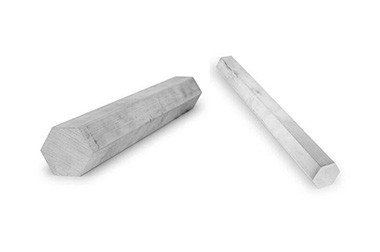

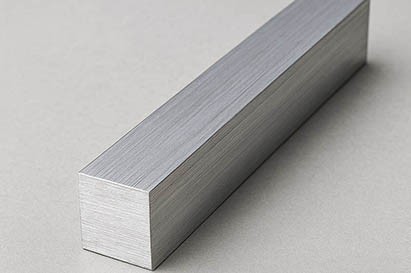

6063 Aluminum Round Bar Extrudability and Surface Finish

Known as the "architectural alloy" due to its ease of extrusion, 6063 can produce thin-walled, complex profiles with tight tolerances and mirror-like surface finish, making it ideal for visible applications. It offers excellent polishing, chemical brightening, and anodizing properties, forming uniform coatings without discoloration or streaks.

6063 Aluminum Round Bar Corrosion Resistance

With its low magnesium content, 6063 exhibits better resistance to stress corrosion cracking compared to high-magnesium alloys (e.g., 5083). It performs well in atmospheric, marine, and mildly acidic environments. It is especially suitable for exterior architectural components that require long-term aesthetic appeal and durability.

6063 Aluminum Round Bar Welding and Machinability

- Weldability: Excellent in all tempers; weld joints have mechanical properties comparable to the base metal, with very low susceptibility to hot cracking

- Machinability: Approximately 70% compared to 2011 alloy; recommended to use low speeds and high feed rates to maintain surface finish and tool life, especially in T6 temper

6063 Aluminum Round Bar Applications

| Application Field | Specific Use |

| Architectural Field | Door and window frames, railings, handrails, curtain wall frames, decorative strips, window channels, and other structural and decorative components, featuring excellent anodizing adaptability and aesthetic performance. |

| Industrial Manufacturing | Irrigation pipes, vehicle structural components, mechanical platforms, mold parts, and components for automated equipment, all as lightweight structural parts. |

| Electrical and Thermal Management | Electrical busbars, conductive rods (IACS conductivity of 55–63%), LED fixtures, heat sinks, benefiting from its excellent electrical and thermal conductivity (~200 W/m·K). |

| Electronics and Communications | Antennas, waveguides, and enclosures for communication equipment and structures. |

| Decoration and Furniture | Furniture legs, mounting brackets, shelves, decorative support rods, featuring excellent polishability and corrosion resistance, suitable for aesthetic applications. |

| Transportation and Marine | Automotive interior parts, lightweight marine accessories, and non-load-bearing aircraft structural components, offering both lightweight and corrosion-resistant advantages. |

6063 Aluminum Round Bar Processing Techniques

Extrusion Forming

Suitable for building components such as door and window frames, curtain wall profiles, accounting for over 70% of global aluminum extrusion production.

Heat Treatment Process

- Solution Treatment: Held at 520°C followed by rapid cooling (water or air quenching)

- Aging Treatment: Natural aging or artificial aging (T6 temper provides higher strength)

Post-treatment

After surface anodizing, color customization is available, widely used for decorative components.

Manufacturing and Processing

- Extrusion: High-speed extrusion, suitable for complex shapes.

- Cold Drawing: Improves dimensional accuracy and surface finish.

- Heat Treatment: T6 tempering, including solution heat treatment and artificial aging, to enhance strength.

Advantages of 6063 Aluminum Round Bar Over Other Alloys

- Corrosion Resistance: Superior to 6061 in harsh environments.

- Formability: Easily extruded into thin-walled or hollow profiles.

- Aesthetic Versatility: Smooth surface is ideal for anodizing and coloring.

Selection Recommendations

The heat treatment temper (e.g., T5/T6) should be selected based on strength requirements, and strict control of composition variation is essential. Air quenching is preferred for thin-walled parts to avoid deformation, while water quenching is recommended for thick-walled parts to ensure quenching depth.