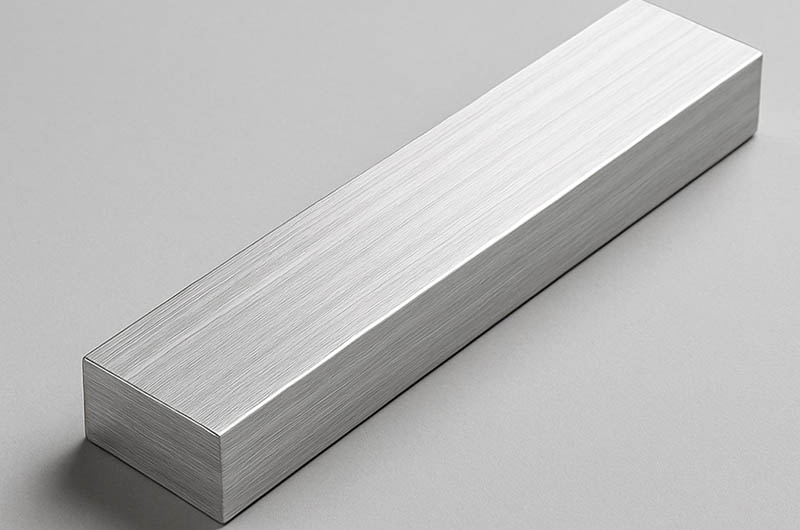

6063 Aluminum Flat Bar

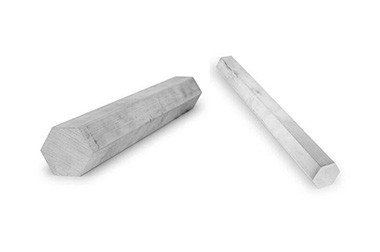

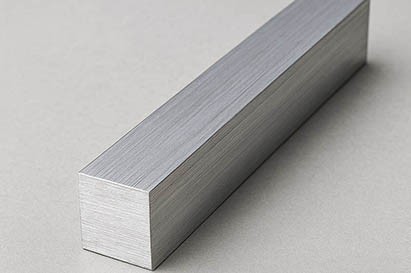

6063 Aluminum Flat Bar is a flat, bar-shaped profile made from 6063 aluminum alloy, which belongs to the Al-Mg-Si series.

6063 aluminum flat bar is a widely used, heat-treatable alloy known for its excellent extrudability, good strength-to-weight ratio, and superior surface finish. It is widely used in architectural decoration, building frames, transportation components, and electrical applications. Its formability, weldability, and surface finish are well-balanced, making it one of the most popular aluminum profiles for decorative and structural uses.

6063 aluminum flat bar is a versatile extrudable alloy, extensively used in the architecture, industrial, and aerospace sectors. It is renowned for its balanced strength, formability, and corrosion resistance, making it the preferred choice for projects requiring both aesthetic appeal and structural reliability.

6063 aluminum flat bar is commonly used in decorative, architectural, and marine applications. Though 6063 aluminum has relatively low strength, it offers excellent corrosion resistance and a smoother surface finish than other aluminum alloys. 6063 aluminum flat bars are available in full sizes and custom cut lengths from stock.

Haomei Aluminum is a direct manufacturer of 6063 aluminum flat bar, with uniform material quality and excellent ductility, suitable for complex processing requirements. We provide precision cutting and bulk customization services to meet the lightweight demands of industries such as building curtain walls, rail transportation, and new energy.

6063 Aluminum Flat Bar Specifications and Tolerances

| Item | Description |

| Size Range | |

| Thickness (inches) | 0.125 – 4 |

| Width (mm/inches) | Up to 200 mm (7.87 inches) |

| Length (m/feet) | Customizable, max length: 4.88 meters (16 feet) |

| Dimensional Tolerance | |

| Flatness | ±0.004 inch per inch of width |

| Angular Tolerance | ±1° – 2° (depending on thickness) |

| Surface Finish and Customization | |

| Surface Type | Rolled surface, standard finish includes minor scratches/marks |

| Anodizing Treatment | Optional clear or black anodizing, providing corrosion resistance and color matching (similar to 3003 or 5052 alloys) |

| Industry Standards | |

| Aerospace Standard | AMS 4156 |

| British Standard | BS H9 |

| U.S. Military Standard | QQ-A-200/9 |

| Certification Systems | |

| Quality Certification | AS9100, ISO 9001, NADCAP |

6063 Aluminum Flat Bar Standards and Specifications

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- AMS 4156 / QQ-A-200/11: Aerospace material specifications for 6063 alloy extrusions.

- UNS A96063: Unified Numbering System designation for 6063 alloy.

6063 Aluminum Flat Bar Temper Options and Heat Treatment

Common tempers: T4 (solution heat-treated), T5 (artificially aged), T6 (solution heat-treated + artificially aged), and T52 (stress relieved)

| Temper | Description |

| 6063 Aluminum Flat Bar – T4 | 6063 Aluminum Flat Bar in T4 temper is solution heat-treated and naturally aged to a substantially stable condition. It offers good formability and moderate strength, making it suitable for applications requiring subsequent forming or welding, such as architectural decoration, window frames, and railings. |

| 6063 Aluminum Flat Bar – T5 | 6063 Aluminum Flat Bar in T5 temper is artificially aged directly after extrusion. It features higher mechanical strength and good dimensional stability, and is commonly used in structural components, industrial tracks, electrical conductors, and assemblies. |

| 6063 Aluminum Flat Bar – T6 | 6063 Aluminum Flat Bar in T6 temper is solution heat-treated and then artificially aged, providing the highest strength and hardness. It is suitable for applications with higher mechanical performance requirements, such as aerospace auxiliary structures, heavy-duty brackets, and mechanical components. |

| 6063 Aluminum Flat Bar – T52 | 6063 Aluminum Flat Bar in T52 temper undergoes heat treatment and stress relief, maintaining good formability and reduced residual stress. It is especially suitable for high-precision structural parts requiring bending or complex machining, such as transportation rails and decorative frames. |

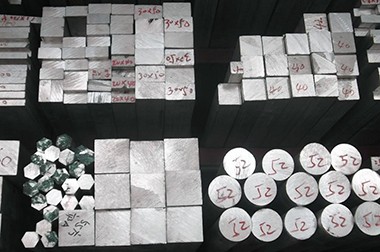

6063 Aluminum Flat Bar Stock Sizes

| Description | Thickness (in) | Width (in) | Temper | Processing/Surface treatment |

| 1" x 2" Aluminum Flat Bar 6063-T52-Extruded | 1" | 2" | 6063-T52 | Extruded |

| 1" x 3" Aluminum Flat Bar 6063-T52-Extruded | 1" | 3" | 6063-T52 | Extruded |

| 1/16" x 1" Aluminum Flat Bar 6063-T52 Extruded | 1/16" | 1" | 6063-T52 | Extruded |

| 1/16" x 1" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/16" | 1" | 6063-T5 | Anodized |

| 1/2" x 1" Aluminum Flat Bar 6063-T52-Extruded | 1/2" | 1" | 6063-T52 | Extruded |

| 1/2" x 1 1/2" Aluminum Flat Bar 6063-T52-Extruded | 1/2" | 1 1/2" | 6063-T52 | Extruded |

| 1/2" x 2" Aluminum Flat Bar 6063-T52-Extruded | 1/2" | 2" | 6063-T52 | Extruded |

| 1/2" x 3" Aluminum Flat Bar 6063-T52-Extruded | 1/2" | 3" | 6063-T52 | Extruded |

| 1/2" x 4" Aluminum Flat Bar 6063-T52-Extruded | 1/2" | 4" | 6063-T52 | Extruded |

| 1/4" x 3/4" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 3/4" | 6063-T52 | Extruded |

| 1/4" x 1" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 1" | 6063-T52 | Extruded |

| 1/4" x 1 1/4" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 1 1/4" | 6063-T52 | Extruded |

| 1/4" x 5/8" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 5/8" | 6063-T52 | Extruded |

| 1/4" x 1 1/2" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 1 1/2" | 6063-T52 | Extruded |

| 1/4" x 2" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 2" | 6063-T52 | Extruded |

| 1/4" x 2 1/2" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 2 1/2" | 6063-T52 | Extruded |

| 1/4" x 4" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 4" | 6063-T52 | Extruded |

| 1/4" x 1" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/4" | 1" | 6063-T5 | Anodized |

| 1/4" x 6" Aluminum Flat Bar 6063-T52-Extruded | 1/4" | 6" | 6063-T52 | Extruded |

| 1/8" x 1/2" Aluminum Flat Bar 6063-T52 Extruded | 1/8" | 1/2" | 6063-T52 | Extruded |

| 1/8" x 3/4" Aluminum Flat Bar 6063-T52 Extruded | 1/8" | 3/4" | 6063-T52 | Extruded |

| 1/8" x 1" Aluminum Flat Bar 6063-T52-Extruded | 1/8" | 1" | 6063-T52 | Extruded |

| 1/8" x 1 1/2" Aluminum Flat Bar 6063-T52-Extruded | 1/8" | 1 1/2" | 6063-T52 | Extruded |

| 1/8" x 2" Aluminum Flat Bar 6063-T52-Extruded | 1/8" | 2" | 6063-T52 | Extruded |

| 1/8" x 2 1/2" Aluminum Flat Bar 6063-T52-Extruded | 1/8" | 2 1/2" | 6063-T52 | Extruded |

| 1/8" x 4" Aluminum Flat Bar 6063-T52-Extruded | 1/8" | 4" | 6063-T52 | Extruded |

| 1/8" x 3" Aluminum Flat Bar 6063-T52-Extruded | 1/8" | 3" | 6063-T52 | Extruded |

| 1/8" x 1/2" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/8" | 1/2" | 6063-T5 | Anodized |

| 1/8" x 1" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/8" | 1" | 6063-T5 | Anodized |

| 1/8" x 1 1/2" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/8" | 1 1/2" | 6063-T5 | Anodized |

| 1/8" x 3/4" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/8" | 3/4" | 6063-T5 | Anodized |

| 1/8" x 2" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/8" | 2" | 6063-T5 | Anodized |

| 1/8" x 2" Anodized Aluminum Flat Bar 6063-T5 Black | 1/8" | 2" | 6063-T5 | Anodized |

| 1/8" x 3/4" Anodized Aluminum Flat Bar 6063-T5 Bronze | 1/8" | 3/4" | 6063-T5 | Anodized |

| 1/8" x 3/4" Anodized Aluminum Flat Bar 6063-T5 Black | 1/8" | 3/4" | 6063-T5 | Anodized |

| 1/8" x 5/8" Aluminum Flat Bar 6063-T52 Extruded | 1/8" | 5/8" | 6063-T52 | Extruded |

| 1/8" x 1 3/4" Anodized Aluminum Flat Bar 6063-T5 Clear | 1/8" | 1 3/4" | 6063-T5 | Anodized |

| 1/8" x 1" Anodized Aluminum Flat Bar 6063-T5 Black | 1/8" | 1" | 6063-T5 | Anodized |

| 1/8" x 1/2" Anodized Aluminum Flat Bar 6063-T5 Black | 1/8" | 1/2" | 6063-T5 | Anodized |

| 3/16" x 3/4" Aluminum Flat Bar 6063-T52-Extruded | 3/16" | 3/4" | 6063-T52 | Extruded |

| 3/16" x 1" Aluminum Flat Bar 6063-T52-Extruded | 3/16" | 1" | 6063-T52 | Extruded |

| 3/16" x 1 1/2" Aluminum Flat Bar 6063-T52-Extruded | 3/16" | 1 1/2" | 6063-T52 | Extruded |

| 3/16" x 2" Aluminum Flat Bar 6063-T52-Extruded | 3/16" | 2" | 6063-T52 | Extruded |

| 3/16" x 1 1/4" Aluminum Flat Bar 6063-T52-Extruded | 3/16" | 1 1/4" | 6063-T52 | Extruded |

| 3/4" x 4" Aluminum Flat Bar 6063-T52-Extruded | 3/4" | 4" | 6063-T52 | Extruded |

| 3/4" x 1 1/2" Aluminum Flat Bar 6063-T52-Extruded | 3/4" | 1 1/2" | 6063-T52 | Extruded |

| 3/8" x 1" Aluminum Flat Bar 6063-T52-Extruded | 3/8" | 1" | 6063-T52 | Extruded |

| 3/8" x 1 1/4" Aluminum Flat Bar 6063-T52-Extruded | 3/8" | 1 1/4" | 6063-T52 | Extruded |

| 3/8" x 1 1/2" Aluminum Flat Bar 6063-T52-Extruded | 3/8" | 1 1/2" | 6063-T52 | Extruded |

| 3/8" x 2" Aluminum Flat Bar 6063-T52-Extruded | 3/8" | 2" | 6063-T52 | Extruded |

| 3/8" x 4" Aluminum Flat Bar 6063-T52-Extruded | 3/8" | 4" | 6063-T52 | Extruded |

6063 Aluminum Flat Bar Corrosion Resistance and Surface Treatments

6063’s composition imparts excellent natural corrosion resistance, particularly in atmospheric and mildly corrosive environments. It’s one of the most anodizable alloys, yielding smooth, uniform oxide layers:

- Anodizing: Commonly used for hard-coat and decorative finishes; improves wear and corrosion resistance, and enhances aesthetic appeal .

- Mill Finish: Smooth extrusion surface, often left uncoated for interior framing applications .

Its resistance to oxidation and pitting makes it ideal for outdoor architectural elements and marine-adjacent uses .

6063 Aluminum Flat Bar Chemical Composition

The main components of 6063 aluminum alloy are:

- Aluminum (Al): >90%, serves as the base material

- Magnesium (Mg): 0.45%-0.9%, forms strengthening phase Mg₂Si with silicon to enhance strength

- Silicon (Si): 0.2%-0.6%, combines with magnesium to form strengthening phase, optimizing heat treatment

- Other elements: Iron (Fe), Copper (Cu), Zinc (Zn), etc., with total impurity content ≤0.35%

A key aspect of the alloy design is controlling Mg:Si = 1.25–1.30 to ensure full formation of the Mg₂Si strengthening phase and avoid excess free magnesium or silicon that could affect performance.

6063 Aluminum Flat Bar Physical Properties

| Performance Indicator | Parameter Range | Remarks |

| Tensile Strength (σb) | 110–250 MPa | Can reach over 205 MPa after T5/T6 heat treatment |

| Yield Strength (σ0.2) | ≥170 MPa | Significantly affected by processing techniques |

| Elongation (δ5) | ≥9% | Indicates good ductility |

| Electrical Conductivity | Moderate | Suitable for busbar and similar applications |

| Corrosion Resistance | Excellent | Further improved by surface treatments (e.g., anodizing) |

6063 Aluminum Flat Bar Manufacturing and Processing

Extrusion and Rolling

6063 flat bar is typically produced using direct extrusion, achieving precise cross-sectional tolerances and requiring minimal downstream processing.

Welding

Excellent weldability in both autogenous welding and filler metal welding processes. Post-weld strength in T6 temper can be restored through localized heat treatment.

Machining

Good machinability (approximately 50% of steel), allowing precise surface finishes and tight tolerances using standard tooling.

Joining

Capable of high-strength joining via welding, brazing, and adhesive bonding — the preferred choice for assemblies requiring high-quality anodized surfaces.

6063 Aluminum Flat Bar Applications

- Architecture and Decoration

- Door and Window Frames

- Curtain Wall Mullions

- Handrails and Railings

- Signage and Display Profiles

- Building and Structural Use

- Light Frames

- Interior Partitions

- Support Frames and Mounting Rails

- Transportation and Automotive

- Dashboard Panels

- Trim Strips and Wires

- Cylinder Tubes (Hard Anodized)

- Electrical and Electronics

- Heat Sink Bars (due to good conductivity, suitable for T5, T52, T6 tempers)

- Cable Trays and Wire Ducts

| Application Field | Specific Uses |

| Aerospace | Aircraft structural components, parts requiring lightweight and moderate strength (compliant with AS9100 certification requirements) |

| Construction Industry | Architectural profiles such as door and window frames, curtain wall support structures, accounting for approximately 70% of total 6063 flat bar applications |

| Electrical Equipment | High and low voltage switch contacts, conductive busbars, etc., taking full advantage of its good conductivity, low resistivity, and excellent bending properties |

| Industrial Products | Heat sinks, agricultural irrigation pipes, furniture accessories, signage, roofing materials, and various types of industrial piping systems |

| Electronics & Communications | Antennas, waveguides, and other precision electronic and communication components that require high dimensional accuracy and conductive performance |

6063 Aluminum Flat Bar Advantages and Limitations

- Advantages: Lightweight, corrosion-resistant, easy to process and form, high overall cost performance

- Limitations: Lower strength compared to 7xxx series aluminum alloys, significant reduction in mechanical properties under high-temperature environments

Comparison Between 6063 Aluminum Flat Bar and Other Alloys

Compared to 6061 alloy, 6063 alloy offers smoother extruded surfaces and superior anodizing characteristics, although with slightly lower strength. When surface quality and formability are prioritized over maximum load-bearing requirements, 6063 alloy is the preferred choice.

Comparison with 6061 Aluminum

| Feature | 6063 | 6061 |

| Strength-to-Weight | Moderate | High |

| Surface Finish | Excellent | Fair |

| Formability | Superior | Moderate |

| Primary Use | Architectural, decorative | Structural, heavy-duty |

6063 Aluminum Flat Bar Production Process

- Melting and Casting: Smelt aluminum, magnesium, and silicon raw materials in proportion, while controlling impurity content

- Extrusion Forming: Extrude into flat bar shape through molds; cross-sectional shapes can be customized

- Heat Treatment: Enhance performance using T5 (air cooling + artificial aging) or T6 (water cooling + artificial aging) processes

- Surface Treatment: Optional anodizing, painting, and other techniques to improve corrosion resistance and appearance

6063 Aluminum Flat Bar uniquely combines good mechanical strength, excellent surface finish, and corrosion resistance. Its heat treatability, weldability, and anodizing potential make it a foundational alloy for applications in construction, structural components, transportation, and electrical systems.