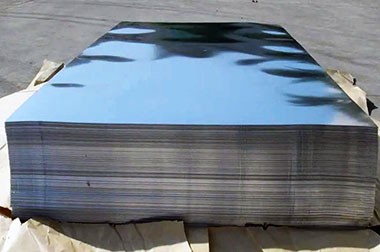

6063 Aircraft Aluminum Sheet Plate

6063 aluminum plate is a sheet material made from 6063 aluminum alloy, which belongs to the Al-Mg-Si series wrought aluminum alloys. It is one of the most widely used alloys in the 6××× series.

6063 aluminum plate is a medium-strength, heat-treatable wrought alloy with good extrudability, excellent surface finish, and high corrosion resistance. It is easy to anodize for an attractive architectural finish and is typically supplied in tempers such as T5, T6, T52, and T53 in accordance with ASTM B209 and ASME SB209 standards.

Typical applications of 6063 aluminum plate include architectural panels, door and window frames, furniture manufacturing, signage, and solar panel mounting frames, where both strength and appearance are important.

6063 aluminum alloy is renowned for its excellent extrudability, corrosion resistance, and surface finish. Due to its balance of mechanical properties and machinability, it is widely used in the architectural and industrial sectors.

What is 6063 aircraft grade aluminum?

6063 aircraft-grade aluminum is a special aluminum alloy that belongs to the 6000 series, primarily alloyed with magnesium and silicon.

It is typically used in applications requiring good extrudability, corrosion resistance, and medium strength.

Specification of 6063 aircraft aluminum sheet

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) |

| 6063 | O, T4, T6, T651 | 0.3-600 | 500-2650 | 500-16000 |

6063 Aluminum Plate Common Tempers and Processes

Tempers and Processing

6063 is available in various tempers, each suited for specific applications:

- T5: Naturally aged after extrusion; good formability and surface finish (e.g., window frames).

- T6: Solution heat treated and artificially aged to improve strength (e.g., structural components).

- T651: T6 followed by stretching to relieve internal stresses, improving machining stability (e.g., aerospace components).

| Temper | Process Description | Characteristic Overview | Common Applications |

| T5 | Air quenched after extrusion and artificially aged | Moderate hardness, good balance of plasticity and strength, excellent surface quality | Architectural profiles, door and window frames, curtain wall structural components, etc. |

| T6 | Full solution heat treatment followed by complete artificial aging | Higher strength than T5, slightly lower plasticity, more stable mechanical properties | Precision mechanical parts, electronic heat dissipation components, etc. |

6063 Aluminum Plate Standards

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet and plate.

- Thickness range: 0.2–300 mm, with a maximum width of up to 2, 500 mm.

- Testing: Includes tensile strength, hardness, and corrosion resistance tests (e.g., pitting, IGC).

6063 aluminum plate is a versatile, corrosion-resistant alloy optimized for architectural and decorative use. Although its strength is lower than that of 6061, its superior extrudability and surface quality make it the preferred choice for applications requiring aesthetics and moderate mechanical properties.

Properties of 6063 Aircraft Aluminum Plate

- Excellent Corrosion Resistance: 6063 aluminum alloy has good corrosion resistance, making it suitable for use in various environments.

- Good Workability: This alloy is easy to extrude and form, making it ideal for manufacturing complex-shaped parts.

- Lightweight: Compared to other metal materials, 6063 aluminum alloy has a lower density, effectively reducing structural weight.

- Good Surface Treatment Capability: 6063 aluminum alloy performs excellently in surface treatments such as anodizing, resulting in a good appearance and wear resistance.

6063 Aluminum Plate Chemical Composition

Main Alloying Elements

- Magnesium (Mg): 0.45 – 0.90% — Forms Mg₂Si during aging, contributing to precipitation hardening.

- Silicon (Si): 0.20 – 0.60% — Combines with magnesium to enhance the alloy’s heat treatment capabilities.

Minor Impurities

- Iron (Fe): ≤ 0.35%

- Copper (Cu): ≤ 0.10%

- Manganese (Mn): ≤ 0.10%

- Chromium (Cr), Zinc (Zn), Titanium (Ti): Each ≤ 0.10%.

6063 Aluminum Plate Mechanical Properties

Strength by Temper

- T1: UTS ≥ 120 MPa, YS ≥ 62 MPa.

- T5: UTS ≥ 140 MPa, YS ≥ 97 MPa.

- T6: Ultimate Tensile Strength (UTS) ≥ 190 MPa, Yield Strength (YS) ≥ 160 MPa; Elongation ≥ 8% (thickness ≤ 3.15 mm) or ≥ 10% (thickness > 3.15 mm).

6063 Aluminum Plate General Physical Properties

- Density: 2.70 g/cm³.

- Young's Modulus: ~69 GPa.

- Thermal Expansion Coefficient: 23.4 µm/m·K.

6063 Aluminum Plate Thermal and Electrical Properties

- Thermal Conductivity: 200 W/m·K (ideal for heat sinks).

- Electrical Resistivity: 3.32×10⁻⁶ ohm·cm.

Aluminium 6063 sheet equivalent grades

| UNS | WNR | DIN | EN | ISO | BS (OLD) | USA |

| A96063 | 3.32206 | AlMgSi0.5 | AW AlMg0, 7Si EN AW 6063 | AlMg0, 7Si | HE9 | AA6063 |

What is stronger 6061 or 6063 aluminum?

6061 aluminum alloy has higher strength, making it suitable for structural applications that bear greater loads. In contrast, 6063 aluminum alloy is better suited for applications requiring higher aesthetic appeal and formability.

6061 aluminum alloy is widely used in applications that require high strength and load-bearing capabilities, such as aircraft structures, automotive parts, ships, and load-bearing frames.

6063 aluminum alloy is typically used in applications where formability and appearance are prioritized, such as architectural window frames, interiors, and lightweight structures.

Applications of 6063 Aircraft Aluminum Plate

6063 is commonly used in aircraft frames, components, and structures where reducing weight and increasing strength are crucial. It is used to manufacture structural components like airframe parts and fuselage.

Aircraft Structural Components

6063 aluminum alloy is often used to manufacture structural components such as frames, fuselages, and wings of aircraft. Its excellent strength-to-weight ratio effectively enhances aircraft performance and fuel efficiency.

Interior Decorative Components

Interior decorations and accessories of aircraft, such as seat frames, luggage compartment frames, and partitions, typically use 6063 aluminum alloy. Its good surface treatment characteristics make it visually appealing and easy to clean and maintain.

Cargo and Cabin Accessories

In cargo holds and other compartments, 6063 aluminum alloy can be used to manufacture various brackets and fixtures, ensuring the safety of cargo and effective use of cabin space.

Cabin and Cockpit Components

6063 aluminum alloy is also used for some components in the cabin and cockpit, such as dashboard frames and control panels. Its lightweight and strength characteristics contribute to increased safety and ease of operation in the cockpit.

6063 aluminum alloy is typically processed through extrusion and rolling, with heat treatment states generally being T5 and T6. T5 refers to natural aging treatment, while T6 refers to artificial aging treatment, with the latter having higher strength and hardness.

What other fields are 6063 aluminum plates used in?

| Application Field | Specific Application Scenarios | Key Characteristics / Uses |

| Construction Industry | Door and window frames, curtain wall support structures, exterior wall cladding, sunshades, decorative trims, railings, light-duty columns, solar panel brackets | High surface finish, easy to extrude, anodizable; accounts for over 70% of aluminum extrusion applications; moderate strength, high weather resistance |

| Transportation | Automobile body panels, fuel pump components, rail transit parts, vehicle frames, ship decorative components, non-load-bearing aerospace structures | Lightweight design, medium strength for non-load-bearing structures; suitable for decorative and functional components |

| Industry and Electronics | Automation machinery parts, communication antennas, waveguides, electronic equipment carriers (e.g., enclosures, heat sinks) | High extrudability, good thermal/electrical conductivity, suitable for precision processing needs |

| Civil and Consumer Products | Indoor/outdoor furniture frames, display racks, illuminated sign panels, guardrails, irrigation pipes, electrical enclosures, piping | Strong weather resistance, easy surface treatment (e.g., anodizing), balances aesthetics and practicality |

Advantages and Limitations of 6063 Aluminum Plate

Advantages of 6063 Aluminum Plate

- Corrosion Resistance: Forms a protective oxide layer, making it highly suitable for marine and outdoor use.

- Surface Treatment: Excellent polishing performance; accepts coatings (e.g., PVC, fluorocarbon coatings).

- Extrudability: Efficiently forms complex profiles.

Limitations of 6063 Aluminum Plate

- Lower strength compared to 6061, not suitable for high-stress applications.

- "Parking Effect": Prolonged room temperature storage after quenching may reduce strength.

Comparison with 6061 Alloy

Compared to 6061 aluminum alloy: 6063 offers better plasticity and greater adaptability for extrusion, while 6061 has slightly higher strength but is more challenging to machine.

In the T6 temper condition, 6061 has approximately 50% higher strength than 6063, whereas 6063 outperforms in formability, surface finish, and anodizing response, making it the preferred choice for complex architectural extrusions rather than heavy-load structural parts.

6063 aluminum plate combines medium strength, excellent extrudability, and outstanding surface quality, making it a versatile material ideal for applications where appearance, corrosion resistance, and precise profiles are critical.

Comparison with 6061 Aluminum

| Property | 6063 | 6061 |

| Strength | Medium (Tensile: ~241 MPa) | High (Tensile: ~310 MPa) |

| Extrudability | Excellent for intricate profiles | Moderate |

| Surface Finish | Superior anodizing results | Good |

| Cost | Slightly higher | Lower |

6063 Aluminum Plate Manufacturing and Standards

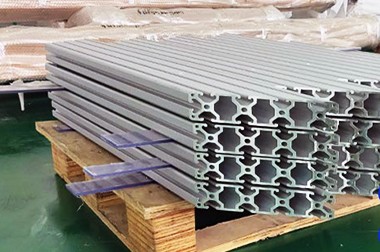

Extrusion and Rolling

6063 is highly regarded for its "architectural" grade extrusion capabilities, allowing for the production of smooth-surfaced, tightly-toleranced complex profiles, plates, and thin-walled components. While it is primarily known as an extrusion alloy, it can also be manufactured into plates in accordance with standards such as ASTM B209, ASME SB209, EN 485-2, and ISO 6361.

Heat Treatment

Solution Heat Treatment: Temperature around 522°C, followed by water quenching.

Age Hardening

T5/T6: 160–180°C, held for 8 hours to achieve peak hardness; alternative temperatures (T52, T53) may be used to adjust surface finish quality.

6063 Aluminum Plate Physical and Processing Properties

- Excellent Plasticity: Easy to extrude and form, suitable for processing complex cross-section profiles, especially ideal for fine architectural structures like doors and windows.

- Outstanding Weldability and Corrosion Resistance: Stable performance after welding, no tendency for stress corrosion, excellent anodizing surface treatment capabilities.

- Medium Strength: Strength can be improved through heat treatment (e.g., T5, T6 conditions), with a typical tensile strength range of 180 MPa to 360 MPa.

6063 Aluminum Plate Surface Treatment and Corrosion Resistance

6063 aluminum exhibits excellent polishing, chemical polishing, and anodizing properties, capable of achieving matte or glossy finishes suitable for architectural applications. Its low magnesium content (< 1%) minimizes susceptibility to stress corrosion cracking, making it suitable for atmospheric and certain marine environments.

6063 aluminum sheet stock list

| Product | Width(inch) | Length(inch) |

| 0.008" Aluminum Sheet 6063-T651 | 12" | 12" |

| 0.01" Aluminum Sheet 6063-T651 | 12" | 24" |

| 0.012" Aluminum Sheet 6063-T651 | 12" | 36" |

| 0.013" Aluminum Sheet 6063-T651 | 12" | 48" |

| 0.014" Aluminum Sheet 6063-T651 | 24" | 24" |

| 0.016" Aluminum Sheet 6063-T651 | 24" | 36" |

| 0.018" Aluminum Sheet 6063-T651 | 24" | 48" |

| 0.02" Aluminum Sheet 6063-T651 | 36" | 36" |

| 0.024" Aluminum Sheet 6063-T651 | 36" | 48" |

| 0.031" Aluminum Sheet 6063-T651 | 48" | 48" |

| 0.039" Aluminum Sheet 6063-T651 | 48" | 144" |

| 0.047" Aluminum Sheet 6063-T651 | 12" | 12" |

| 0.059" Aluminum Sheet 6063-T651 | 12" | 24" |

| 0.063" Aluminum Sheet 6063-T651 | 12" | 36" |

| 0.071" Aluminum Sheet 6063-T651 | 12" | 48" |

| 0.079" Aluminum Sheet 6063-T651 | 24" | 24" |

| 0.098" Aluminum Sheet 6063-T651 | 24" | 36" |

| 0.118" Aluminum Sheet 6063-T651 | 24" | 48" |

| 0.157" Aluminum Sheet 6063-T651 | 36" | 36" |

| 0.197" Aluminum Sheet 6063-T651 | 36" | 48" |

| 0.236" Aluminum Sheet 6063-T651 | 48" | 48" |

| 0.008" Aluminum Sheet 6063-T5 | 48" | 144" |

| 0.01" Aluminum Sheet 6063-T5 | 12" | 12" |

| 0.012" Aluminum Sheet 6063-T5 | 12" | 24" |

| 0.013" Aluminum Sheet 6063-T5 | 12" | 36" |

| 0.014" Aluminum Sheet 6063-T5 | 12" | 48" |

| 0.016" Aluminum Sheet 6063-T5 | 24" | 24" |

| 0.018" Aluminum Sheet 6063-T5 | 24" | 36" |

| 0.02" Aluminum Sheet 6063-T5 | 24" | 48" |

| 0.024" Aluminum Sheet 6063-T5 | 36" | 36" |

| 0.031" Aluminum Sheet 6063-T5 | 36" | 48" |

| 0.039" Aluminum Sheet 6063-T5 | 48" | 48" |

| 0.047" Aluminum Sheet 6063-T5 | 48" | 144" |

| 0.059" Aluminum Sheet 6063-T5 | 12" | 12" |

| 0.063" Aluminum Sheet 6063-T5 | 12" | 24" |

| 0.071" Aluminum Sheet 6063-T5 | 12" | 36" |

| 0.079" Aluminum Sheet 6063-T5 | 12" | 48" |

| 0.098" Aluminum Sheet 6063-T5 | 24" | 24" |

| 0.118" Aluminum Sheet 6063-T5 | 24" | 36" |

| 0.157" Aluminum Sheet 6063-T5 | 24" | 48" |

| 0.197" Aluminum Sheet 6063-T5 | 36" | 36" |

| 0.236" Aluminum Sheet 6063-T5 | 36" | 48" |

| 0.008" Aluminum Sheet 6063-T6 | 48" | 48" |

| 0.01" Aluminum Sheet 6063-T6 | 48" | 144" |

| 0.012" Aluminum Sheet 6063-T6 | 12" | 12" |

| 0.013" Aluminum Sheet 6063-T6 | 12" | 24" |

| 0.014" Aluminum Sheet 6063-T6 | 12" | 36" |

| 0.016" Aluminum Sheet 6063-T6 | 12" | 48" |

| 0.018" Aluminum Sheet 6063-T6 | 24" | 24" |

| 0.02" Aluminum Sheet 6063-T6 | 24" | 36" |

| 0.024" Aluminum Sheet 6063-T6 | 24" | 48" |

| 0.031" Aluminum Sheet 6063-T6 | 36" | 36" |

| 0.039" Aluminum Sheet 6063-T6 | 36" | 48" |

| 0.047" Aluminum Sheet 6063-T6 | 48" | 48" |

| 0.059" Aluminum Sheet 6063-T6 | 48" | 144" |

| 0.063" Aluminum Sheet 6063-T6 | 12" | 12" |

| 0.071" Aluminum Sheet 6063-T6 | 12" | 24" |

| 0.079" Aluminum Sheet 6063-T6 | 12" | 36" |

| 0.098" Aluminum Sheet 6063-T6 | 12" | 48" |

| 0.118" Aluminum Sheet 6063-T6 | 24" | 24" |

| 0.157" Aluminum Sheet 6063-T6 | 24" | 36" |

| 0.197" Aluminum Sheet 6063-T6 | 24" | 48" |

| 0.236" Aluminum Sheet 6063-T6 | 36" | 36" |