6063 Aerospace Aluminum Bar

6063 aluminum bar is an Al-Mg-Si series aluminum alloy material with magnesium (Mg) and silicon (Si) as the main alloying elements. It belongs to heat-treatable strengthened, low-alloyed, high-plasticity wrought aluminum alloys.

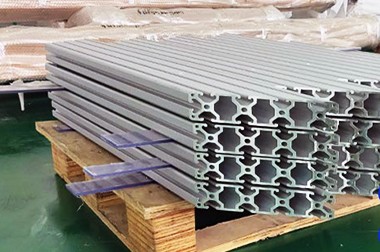

6063 alloy is a widely used medium-strength forged aluminum alloy in the 6xxx series. It is the most commonly used aluminum alloy in extrusion forming, featuring excellent extrudability and high-quality surface finish, making it suitable for visible architectural applications. Its balanced mechanical properties, corrosion resistance, weldability, and surface treatment compatibility make it the preferred "architectural alloy" for door and window frames, railings, pipes, and decorative profiles.

6063 aluminum bar is a widely used aluminum alloy, known for its excellent extrusion performance, corrosion resistance, and surface finish.

6063 aerospace aluminum is an aluminum-magnesium-silicon alloy, widely used due to its excellent formability, corrosion resistance, and medium strength. Its lightweight and ease of fabrication make it highly regarded in aerospace applications.

6063 aerospace aluminum bars combine strength, formability, and corrosion resistance, making them a popular choice in the aerospace industry. They are easy to extrude and weld, lightweight, and capable of meeting the stringent demands of various aerospace applications.

Specs of 6063 T5/T6/T52 aluminum flat bar

| Alloy | 6063 |

| Temper | T4, T5, T6, T52, O |

| Out diameter | 6mm-150mm |

| Length | 4000mm, 6000mm |

| Standard | BS H9 Alloy 6063 DTD 372B 6063 Bars and Sections AMS 4156 6063-T6 Extrusions QQ-A-200/9 6063 |

6063 Aluminum Bar Heat Treatment & Tempers

6063 undergoes solution treatment (about 522 °C) and water quenching, followed by aging treatment to achieve T5 or T6 temper. It can be annealed to the O condition by heating to 415 °C, holding for 2–3 hours, and cooling slowly; partial stress relief can be achieved by uncontrolled cooling at 345 °C. Other special tempers include T52, T53, T54, T55, and T832 to enhance performance.

- T4: Solution heat-treated and naturally aged; offers good formability for hydroforming tubes and bending.

- T5/T52: Artificially aged after extrusion; balances strength and surface finish, suitable for architectural uses.

- T6: Solution heat-treated and artificially aged for maximum strength, commonly used for structural components.

This alloy is easily extruded into complex shapes and can be cold-formed or hot-formed. It also supports welding (e.g., TIG, MIG) and surface treatments such as anodizing.

6063 Aluminum Bar Standards

6063 bars and profiles can be produced according to multiple standards:

- ASTM B221: Specifications for extruded bars, rods, wires, profiles, and tubes.

- AMS 4156 / QQ-A-200/8: Aerospace material specifications.

- EN 755-2 / ISO 6361: European and international standards for extruded profiles.

- EN 573-3/BS H9: European standards for structural and architectural applications.

6063 aluminum bar is a versatile material acclaimed for its extrudability, corrosion resistance, and aesthetics. Its adaptability in architecture, electrical applications, and aerospace makes it a cornerstone of modern engineering.

6063 Aluminum Bar Surface Treatments and Finishing

- Anodizing: 6063 can form a uniform, decorative oxide layer; widely used in architecture with good color retention and durability.

- Powder Coating/Painting: Can strongly adhere to its smooth extruded surface.

- Chemical Brightening/Polishing: Enables high gloss and improved corrosion resistance.

Characteristics of 6063 Aerospace Aluminum Bar

- Strength: Although not as strong as some other aerospace aluminum alloys (such as 7075), 6063 provides good strength for structural applications.

- Corrosion resistance: 6063 aluminum has excellent corrosion resistance, making it suitable for various environmental conditions, including marine applications.

- Weldability: This alloy is known for its good weldability, which is crucial for aerospace applications where components often need to be joined.

- Formability: 6063 aluminum is easy to extrude and can be formed into complex shapes and profiles. It can also be easily machined and shaped to specific designs.

- Surface treatment: The 6063 alloy can be anodized and painted to enhance aesthetics and provide additional corrosion protection.

Chemical composition of 6063 aluminum alloy

| 6063 Alloy % | |

| Si | 0.20-0.60 |

| Fe | 0.35 |

| Cu | 0.10 |

| Mn | 0.10 |

| Mg | 0.45-0.90 |

| Ti | 0.10 |

| Al | Remainder |

Mechanical property of 6063 aluminum bar

| Alloy | Temper | Tension strength(MPa) | Yield strength(MPa) | Elongation(%) | Hardness(HB) |

| 6063 | O | ≤90 | ≤50 | ≥15 | ≤35 |

| T4 | ≥130 | ≥60 | ≥12 | 50-75 | |

| T5 | ≥160 | ≥110 | ≥8 | 60-85 | |

| T6 | ≥205 | ≥170 | ≥8 | 75-90 |

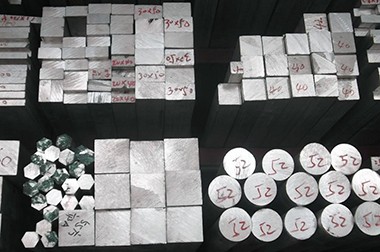

Haomei 6063 aerospace aluminum bar hot selling alloy series

6063 T4 Aluminum Bar Rod

The 6063 T4 aluminum bar rod is an extruded product that has been solution heat-treated and then naturally aged to achieve its mechanical properties.

Properties: This temper offers moderate strength, excellent corrosion resistance, and good workability. It is often used in applications where good mechanical properties and a smooth surface finish are required, such as architectural applications.

6063 T5 Aluminum Bar Rod

The 6063 T5 aluminum bar rod is also an extruded product, but it is cooled from the extrusion process and then artificially aged.

Properties: This temper provides higher strength than T4, making it suitable for structural applications. It is known for its good surface finish and corrosion resistance, often used in architectural frames, window frames, and other applications.

6063 T6 Aluminum Bar Rod

The 6063 T6 aluminum bar rod undergoes a more rigorous heat treatment process, involving solution heat treatment followed by artificial aging.

Properties: T6 offers the highest strength among the 6063 tempers while maintaining good corrosion resistance and workability. It is commonly used in structural applications and components requiring enhanced strength.

6063 T52 Aluminum Bar Rod

The 6063 T52 aluminum bar rod is a variation of the T5 temper but with specific modifications in the manufacturing process that enhance its properties.

Properties: T52 offers improved strength compared to T5 and is often used in applications where higher strength and good weldability are required. It still retains good corrosion resistance and is suitable for structural applications.

6063 Aerospace Al Extruded Bar

This is an extruded bar made from 6063 aluminum alloy, specifically designed for aerospace applications.

Properties: It typically meets stringent aerospace standards, offering a lightweight, high-strength solution with excellent corrosion resistance. This type is used in various components of aircraft structures.

6063 Aerospace Aluminum Forged Bar

This product is made from the 6063 aluminum alloy and has undergone a forging process to enhance its mechanical properties.

Properties: Forged bars are known for superior strength and toughness compared to extruded bars, making them suitable for high-stress aerospace components and applications.

6063 Aerospace Aluminum Round Bar

A round bar made from the 6063 aluminum alloy, specifically tailored for aerospace applications.

Properties: This form is commonly used for rods, shafts, and other components that require a round cross-section, providing a good strength-to-weight ratio and excellent corrosion resistance.

6063 Aerospace Aluminum Square Bar

A square-shaped bar made from the 6063 aluminum alloy, designed for aerospace applications.

Properties: This square profile is often used in structural components and frames, offering a balance of lightweight properties and mechanical strength.

6063 Aerospace Aluminum Flat Bar

A flat bar made from the 6063 aluminum alloy, engineered for aerospace use.

Properties: This versatile flat bar can be utilized in a variety of applications, including brackets, supports, and structural elements, where a flat profile is advantageous.

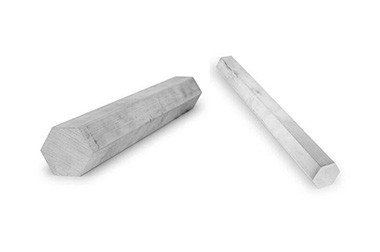

6063 Aerospace Aluminum Hex Bar

A hexagonal bar made from the 6063 aluminum alloy, specifically designed for aerospace applications.

Properties: The hex shape is beneficial for fasteners and components that require a unique profile, combining high strength with a lightweight design.

6063 Aluminum Bar Physical Properties

- Density: 2.69 g/cm³ (0.097 lb/in³)

- Thermal Conductivity: 201–218 W/m·K

- Linear Thermal Expansion Coefficient: 23.4 µm/m·K

- Specific Heat Capacity: ≈ 900 J/kg·K

- Electrical Resistivity: 30–35 nΩ·m

6063 Aluminum Bar Stock

Round Bar Stock Sizes (6063-T52 Extruded)

| Description | Diameter (inches) |

| ⅛" 6063 T52 Aluminum Round Bar | 0.125 |

| 3⁄16" 6063 T52 Aluminum Round Bar | 0.1875 |

| ¼" 6063 T52 Aluminum Round Bar | 0.25 |

| 5⁄16" 6063 T52 Aluminum Round Bar | 0.3125 |

| 3⁄8" 6063 T52 Aluminum Round Bar | 0.375 |

| 7⁄16" 6063 T52 Aluminum Round Bar | 0.4375 |

| ½" 6063 T52 Aluminum Round Bar | 0.5 |

| 9⁄16" 6063 T52 Aluminum Round Bar | 0.5625 |

| 5⁄8" 6063 T52 Aluminum Round Bar | 0.625 |

| ¾" 6063 T52 Aluminum Round Bar | 0.75 |

| 7⁄8" 6063 T52 Aluminum Round Bar | 0.875 |

| 1" 6063 T52 Aluminum Round Bar | 1 |

| 1 1⁄8" 6063 T52 Aluminum Round Bar | 1.125 |

| 1 1⁄4" 6063 T52 Aluminum Round Bar | 1.25 |

| 1 1⁄2" 6063 T52 Aluminum Round Bar | 1.5 |

| 1 3⁄4" 6063 T52 Aluminum Round Bar | 1.75 |

| 2" 6063 T52 Aluminum Round Bar | 2 |

| 2 1⁄2" 6063 T52 Aluminum Round Bar | 2.5 |

| 3" 6063 T52 Aluminum Round Bar | 3 |

| 4" 6063 T52 Aluminum Round Bar | 4 |

| 5" 6063 T52 Aluminum Round Bar | 5 |

| 6" 6063 T52 Aluminum Round Bar | 6 |

Flat (Rectangular) Bar Sizes (6063-T52 Extruded)

| Description | Thickness (in) | Width (in) |

| 0.125" x 0.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 0.5 |

| 0.125" x 0.625" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 0.625 |

| 0.125" x 0.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 0.75 |

| 0.125" x 1" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 1 |

| 0.125" x 1.25" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 1.25 |

| 0.125" x 1.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 1.5 |

| 0.125" x 1.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 1.75 |

| 0.125" x 2" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 2 |

| 0.125" x 0.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.125 | 0.75 |

| 0.1875" x 0.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 0.5 |

| 0.1875" x 0.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 0.75 |

| 0.1875" x 1" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 1 |

| 0.1875" x 1.25" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 1.25 |

| 0.1875" x 1.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 1.5 |

| 0.1875" x 2" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 2 |

| 0.1875" x 2.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.1875 | 2.5 |

| 0.25" x 0.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 0.5 |

| 0.25" x 0.625" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 0.625 |

| 0.25" x 0.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 0.75 |

| 0.25" x 1" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 1 |

| 0.25" x 1.25" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 1.25 |

| 0.25" x 1.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 1.5 |

| 0.25" x 1.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 1.75 |

| 0.25" x 2" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 2 |

| 0.25" x 2.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 2.5 |

| 0.25" x 3" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.25 | 3 |

| 0.375" x 0.625" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 0.625 |

| 0.375" x 0.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 0.75 |

| 0.375" x 1" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 1 |

| 0.375" x 1.25" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 1.25 |

| 0.375" x 1.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 1.5 |

| 0.375" x 2" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 2 |

| 0.375" x 3" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.375 | 3 |

| 0.5" x 0.75" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 0.75 |

| 0.5" x 1" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 1 |

| 0.5" x 1.25" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 1.25 |

| 0.5" x 1.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 1.5 |

| 0.5" x 2" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 2 |

| 0.5" x 2.5" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 2.5 |

| 0.5" x 3" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 3 |

| 0.5" x 6" 6063-T52 Aluminum Flat (Rectangular) Bar | 0.5 | 6 |

Applications of 6063 Aerospace Aluminum Bar

6063 aerospace aluminum bar is an aluminum alloy with an excellent strength-to-weight ratio and outstanding corrosion resistance, widely used in the aerospace field. Due to its moderate strength, good formability, and durability, it is used in numerous critical structural and non-structural components.

Aircraft Structural Components

6063 aluminum bars are often used in the overall structure of aircraft, such as frames and brackets. These structures require materials that are both lightweight and capable of withstanding certain mechanical stresses, and 6063 performs well in these areas.

Advantage: Its corrosion resistance ensures reliability during long-term use in humid environments, especially when facing climate changes, moisture, and salt spray at high altitudes.

Fuselage Frames and Brackets

Fuselage frames act as the skeleton of the aircraft and must have high strength to support the aircraft's own weight and the dynamic loads during flight. The formability of 6063 aluminum bars allows them to be shaped into complex frames and brackets through various processes, such as extrusion and welding.

Advantage: The material is lightweight, reducing the overall weight of the aircraft and improving fuel efficiency while maintaining sufficient strength.

Wing Structures

The strength and rigidity of the wings are critical for the safe flight of the aircraft. 6063 aluminum bars are used to manufacture secondary load-bearing components in the wing structure, such as ribs and support parts.

Advantage: The ductility of 6063 aluminum allows for the creation of complex shapes during the manufacturing process, while its moderate strength is sufficient to handle the aerodynamic loads that the wings endure.

Landing Gear and Mounting Brackets

The landing gear, being the primary load-bearing structure during takeoff and landing, is usually made of high-strength materials. However, the mounting brackets and some auxiliary components of the landing gear can be made from 6063 aluminum bars due to their moderate strength and good machinability.

Advantage: 6063 aluminum bars provide adequate support while reducing the overall weight of the aircraft, extending its lifespan.

Interior Components and Fixtures

Interior components like seat brackets, luggage racks, door frames, and other non-load-bearing parts can be made from 6063 aluminum bars. These parts require materials with lower strength but higher demands for lightweight and aesthetic durability.

Advantage: 6063 aluminum bars are not only lightweight but also easy to surface treat, such as anodizing, to give them a more textured appearance while providing wear and corrosion resistance.

6063 Aluminum Bar Production Process

- Primarily produced through extrusion, combined with solution treatment (500–530°C) and aging treatment (175°C/8h) for strengthening.

- Mg/Si ratio should be controlled around 1.73 to reduce the negative impact of free Si on performance.

Industries Where 6063 Aluminum Bar Is Also Applied

- Construction Industry: Dominant sector, used for door and window frames, curtain wall structures, and other architectural profiles, accounting for over 70% of aluminum extrusion demand.

- Industrial Manufacturing: Used in automotive parts (body, engine components), electronic devices (antennas, waveguides), mechanical equipment (automation parts, molds), etc.

- Special Applications: Irrigation pipes, rail transit facilities, and non-load-bearing components in aerospace (e.g., cabin structures).

| Industry Category | Specific Application Parts or Uses |

| Construction | Door and window frames, curtain wall systems, eave structures, solar panel frames, architectural decorative components |

| Railings and Handrails | Stair and balcony handrails, road and bridge guardrails, public area fences, landscape railing systems |

| Pipes and Tubing | Aluminum pipes for irrigation systems, fluid transport aluminum tubes, electrical conduits, water treatment and air circulation duct systems |

| Furniture and Accessories | Commercial display racks, retail shelving, adjustable shelving structures, modern aluminum office furniture frames, household furniture supports and frames |

| Heat Sinks and Electrical | T5/T6 grade aluminum bars widely used for heat sink manufacturing, power enclosures, LED heat dissipation components, electrical control boxes, parts requiring heat dissipation and strength |

| Electrical | Busbars, power distribution units, low-voltage substation components, electrical connectors, distribution board structures, conductive tracks, grounding components |

| Industrial Manufacturing | Conveyor system rollers and brackets, industrial railings, safety fences, mechanical equipment frames, agricultural irrigation pipelines, support structures for automation equipment |

6063 Aluminum Bar Extrusion and Manufacturing

6063 has a low critical shear stress, allowing it to be extruded into thin-walled, complex hollow shapes such as flat, angular, channel, round, and square cross-sections. Its surface is exceptionally smooth, making it highly suitable for anodizing. It offers good machinability (moderate), weldability, and brazability, and is easy to polish, chemically polish, dye, and anodize.

Advantages of 6063 Aluminum Over Other Alloys

- Surface Quality: Superior to 6061 alloy, making it an ideal choice for visible architectural elements.

- Corrosion Resistance: Performs better than many alloys in harsh environments, including marine conditions.

- Machinability: Easy to extrude into complex profiles, though slightly less strong than 6061 alloy.

The wide application of 6063 aluminum bars is due to their excellent strength-to-weight ratio, good formability, and outstanding corrosion resistance. They are suitable for a variety of applications, from aircraft structures to interior fittings, enhancing aircraft performance and efficiency while reducing material and maintenance costs.