2024 T3 T4 Aerospace Aluminum Sheet Plate

2024 T3 and 2024 T4 are common aluminum alloys used in aviation, widely applied in aerospace and other high-performance fields.

2024 T3 and T4 aluminum alloys are high-strength materials suitable for structural applications that require high strength and low weight, but they have certain limitations in corrosion resistance and weldability.

What is 2024 Aircraft Grade Aluminum?

2024 aluminum is one of the earliest high-strength aluminum alloys used in the aerospace industry. Compared with other aluminum alloys, 2024 aluminum has a higher specific strength (strength-to-weight ratio), which means it can provide higher strength at the same weight or achieve weight reduction for the same strength requirement.

2024 aluminum is known for its excellent strength-to-weight ratio and fatigue resistance. It is mainly used in aircraft wing and fuselage structures. Although it has high strength, it is prone to corrosion, so it is often clad with other aluminum alloys for protection.

Specifications of 2024 Aluminum Sheet

- Bare aircraft aluminum sheet plate standard:QQ-A-250/4, AMS 4035, AMS 4037, AMS 4027, FMS 10101

- Clad aircraft aluminum sheet plate standard:QQ-A-250/5, AMS 4040, AMS 4041, BMS 7-305

- Haomei accreditations: AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

2024 aluminum Tempers

- 2024 aluminum O temper (annealed) achieves maximum softness and ductility through full annealing. The tensile strength is usually between 140-210MPa, and elongation can reach 10-25%. Suitable for deep drawing, bending, and other processes requiring large deformation.

- 2024 aluminum T3 temper solution treated, cold worked, and naturally aged. Tensile strength can reach 400-430MPa, yield strength around 270-280MPa. Widely used in aerospace structural components, high-stress mechanical parts, etc.

- 2024 aluminum T351 temper solution treated, stress-relieved by stretching, and naturally aged. Tensile strength can reach 470MPa, yield strength around 325MPa. Particularly suitable for precision machined parts with high dimensional stability requirements.

- Alclad 2024-T3 has a surface clad with a layer of pure aluminum or aluminum alloy in T3 temper. Significantly improves corrosion resistance, especially intergranular corrosion and stress corrosion resistance. Widely used in the aerospace industry.

- 2024 aluminum T4 temper solution treated and naturally aged. Tensile strength about 470MPa, yield strength around 325MPa. Performance remains stable in working environments below 150°C, and strength can even exceed 7075 alloy at temperatures above 125°C.

- 2024 aluminum T6 temper solution treated and artificially aged. Tensile strength can reach 425-470MPa, yield strength around 325MPa, but elongation is usually low. Suitable for applications requiring high strength but low ductility.

- 2024 aluminum T851 temper solution treated, stress-relieved by stretching, and artificially aged. Tensile strength can reach 470MPa, yield strength around 325MPa. Offers excellent stress corrosion resistance, suitable for high-temperature applications.

- 2024 aluminum T81 temper solution treated, cold worked, and artificially aged. Tensile strength can reach 485MPa, yield strength around 450MPa. Mainly used in applications requiring extremely high strength, such as high-strength structural components and special mechanical parts.

Comparison and selection guide of 2024 aluminum tempers

| Temper | Processing | Main Characteristics | Typical Applications |

| O | Annealed | Low strength, high ductility | Semi-finished products for further processing |

| T3 | Solution treated → Cold worked → Naturally aged | High strength, good formability | Aerospace structural components, mechanical parts |

| T351 | Solution treated → Stress-relieved by stretching → Naturally aged | High dimensional stability | Precision machined parts, molds |

| T4 | Solution treated → Naturally aged | High strength, medium formability | Structural parts, automotive components |

| T6 | Solution treated → Artificially aged | High strength, low ductility | High-stress parts, molds |

| T851 | Solution treated → Stress-relieved by stretching → Artificially aged | High strength, high corrosion resistance | Aerospace structural components |

| T81 | Solution treated → Cold worked → Artificially aged | Ultra-high strength, low toughness | Special high-strength parts |

When selecting the appropriate 2024 aluminum temper, the following factors should be considered:

- Strength requirement: Choose the suitable temper according to the required strength level. For extremely high strength demands, consider T81 or T851 temper.

- Processing performance: For parts that require further processing, choose O or T3 temper; for parts without further processing, T4 or T6 temper can be selected.

- Dimensional stability: For applications with high dimensional stability requirements, select stress-relieved tempers such as T351 or T851.

- Corrosion resistance: In corrosive environments, consider Alclad-treated tempers (e.g., Alclad 2024-T3 or T4).

- Cost factors: Processing costs vary for different tempers. Balance between performance requirements and cost should be achieved.

2024 alloy product forms and specifications

- 2024 alloy plate thickness usually 0.3-600mm, width 800-2600mm, length 500-16000mm. Common tempers: O, T3, T4, T6, T351, T851, etc. Typical applications: aircraft skin, structural parts, automotive components, etc.

- 2024 alloy sheet thickness usually 0.2-6.0mm, width 500-2500mm, length 500-10000mm. Common tempers: O, T3, T4, T351, etc. Typical applications: aircraft skin, interior components, electronic device casings, etc.

- 2024 alloy bar diameter usually 3.0-500mm, length 1-5 meters. Common tempers: T3, T4, T351, T851, etc. Typical applications: structural components, mechanical parts, shafts, etc.

- 2024 alloy tube outer diameter 4-300mm, wall thickness 0.5-10mm, length 1-5 meters. Common tempers: T3, T4, T351, etc. Typical applications: hydraulic systems, structural parts, decorative tubes, etc.

- 2024 alloy extrusion can produce various complex cross-sectional shapes, cross-section size usually not exceeding 500mm×500mm. Common tempers: T4, T6, T3511, etc. Typical applications: structural components, frames, decorative parts, etc.

- Alclad 2024 surface clad with a layer of pure aluminum or aluminum alloy. Cladding thickness usually 2.5-5% of total thickness. Common tempers: Alclad 2024-T3, Alclad 2024-T4, etc. Typical applications: aircraft skin, wing structures, etc.

Other product forms of 2024 alloy

In addition to the main product forms mentioned above, 2024 aluminum alloy is also available in the following forms:

- Wire: diameter usually 0.1-20mm, mainly used for rivets, welding wires, etc.

- Strip: thickness usually 0.03-3mm, width usually 100-1200mm, supplied in coils

- Forging: can be customized to various shapes and sizes according to customer requirements, mainly used for high-stress structural components

Each product form has its own characteristics and the appropriate form can be selected according to specific application requirements.

2024 Alloy Common Trade Names

UNS A92024, Al2024-O, Alclad 2024-O, AA2024-T3, Al2024-T3, Alclad 2024-T3, UNS A82024, Alclad 2024-T4/T351, Al2024-T4, UNS A82024, Alclad 2024-T851

2024 Alloy Properties

- Excellent strength-to-weight ratio makes 2024 alloy an ideal choice for critical applications where weight reduction is needed without compromising strength.

- Outstanding fatigue resistance, capable of withstanding repeated stress, making it suitable for dynamically loaded applications.

- Heat-treatable, enabling performance enhancement through appropriate thermal treatment to achieve desired mechanical properties.

- Welding has certain limitations; friction welding is more suitable, while other welding techniques may lead to cracking.

- Relatively corrosion-sensitive; the copper content in 2024 alloy improves strength but also makes it more susceptible to corrosion. Cladding with other aluminum alloys is commonly used to address this issue.

Advantages of 2024 Aerospace Aluminum Sheet Plate

- Lightweight: Compared to traditional steel, 2024 aluminum alloy significantly reduces component weight while ensuring strength.

- Strength: Exhibits excellent tensile strength, suitable for bearing high loads during flight.

- Fatigue Performance: Outstanding fatigue performance ensures stability during long-term use.

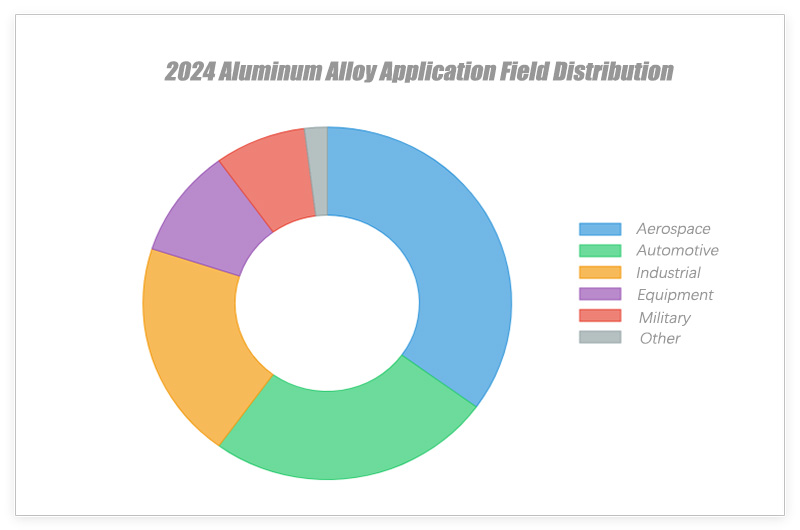

Applications of Aluminium Alloy 2024

Applications of Aluminium Alloy 2024 in Various Fields

- Aerospace Aluminium alloy 2024 is widely used in aircraft structural components (wing skins, fuselage frames, etc.), interior components, rivets, and spacecraft parts. Typical application cases include structural components of large aircraft such as Boeing 787 and Airbus A380.

- Automotive Industry With the increasing demand for lightweight vehicles, Aluminium alloy 2024 is increasingly applied in body structural components, chassis parts, wheels, and engine components. For example, the Tesla Model S body uses a 2036 alloy (similar to 2024) hydraulically formed frame, reducing the body weight by 200kg.

- Industrial and Mechanical Manufacturing In industrial and mechanical manufacturing, Aluminium alloy 2024 is mainly used for mold manufacturing, high-precision parts, mechanical structural components, and hydraulic system parts. Its high hardness and excellent machinability make it an ideal material for mold production.

- Sports Equipment and Consumer Products Aluminium alloy 2024 also finds wide application in sports equipment and consumer products, such as bicycle frames, golf clubs, climbing equipment, and electronic device housings. For example, Giant TCR series uses 2017 alloy (similar to 2024) tubing; the frame weighs only 1.4kg yet can withstand 200kg of impact force.

- Construction and Decoration Although Aluminium alloy 2024 is not as widely used in construction as alloys like 6061, it is still applied in certain special cases, such as architectural decoration, special structural components, and decorative parts. For instance, the CITIC Tower in Beijing uses 2A16 alloy (similar to 2024) profiles to support the glass curtain wall.

- Military and Protection Aluminium alloy 2024 has special applications in military and protective fields, such as ballistic armor, weapon system components, and lightweight structural components for military vehicles. In these applications, Aluminium alloy 2024 is usually used in T6 or T851 temper to provide maximum strength and impact resistance.

Applications of Aluminium Alloy 2024 in Aerospace

Aluminium alloy 2024 has extensive applications in the aerospace sector, mainly due to its excellent strength-to-weight ratio, fatigue performance, and machinability (4). Its main applications include:

- Aircraft structural components: wing skins, fuselage frames, ribs, spars, bulkheads, and other major structural parts

- Interior components: aircraft interior fittings, floor support structures, etc.

- Rivets: high-strength rivets, especially Alclad 2024-T4 rivets, widely used for aircraft structural connections

- Spacecraft components: satellite structures, rocket parts, etc.

In aerospace applications, Aluminium alloy 2024 is usually used in T3, T4, T351, or Alclad tempers to meet high strength, lightweight, and corrosion resistance requirements.

Main Advantages and Limitations of AA2024 Alloy

Main Advantages of AA2024 Alloy

- High strength: tensile strength can reach above 470MPa, approaching that of some steels

- Excellent specific strength: density is only about 1/3 of steel, yet strength can reach about half of steel

- Good machinability: excellent cutting and forming performance

- Outstanding fatigue resistance: performs well under cyclic loading

- Good thermal stability: maintains performance in operating environments below 150°C

Main Limitations of AA2024 Alloy

- Poor corrosion resistance: high copper content makes it prone to intergranular corrosion in humid or salt-spray environments

- Poor weldability: prone to cracking during fusion welding, usually requiring special welding techniques

- Stress corrosion sensitivity: certain tempers (e.g., T6) are susceptible to stress corrosion

- Higher cost: compared with common aluminum alloys (like 6061), 2024 aluminum alloy is more expensive

Machining and Heat Treatment Characteristics of AA2024 Alloy

An important characteristic of AA2024 alloy is that it can be strengthened through heat treatment. The alloy exhibits good formability in hot, annealed, and newly quenched states, suitable for various processing methods. However, the heat treatment process requires strict control, with precise temperature and time management to achieve optimal performance.

Another important characteristic of AA2024 alloy is its excellent machinability, especially suitable for high-precision applications. However, its weldability is relatively poor; fusion welding can easily cause cracks, usually requiring special welding techniques or dedicated filler wires (such as 4043 aluminum-silicon welding wire). To improve weldability, alternatives such as riveting or bolted connections can also be used.

AA2024 alloy has relatively poor corrosion resistance, especially in salt spray or humid environments where intergranular corrosion may occur. To address this issue, two industrial solutions are commonly applied:

- First, cladding the surface with a pure aluminum layer (Alclad process), providing sacrificial anode protection.

- Second, improving corrosion resistance through anodizing or applying protective coatings.

Alum 2024 Available for Sale from Haomei Aluminum

alum 2024 plate

alum 2024 plate is a high-strength aluminum sheet widely used in aerospace, automotive, and structural applications due to its excellent fatigue resistance and good machinability.

- alum 2024 t851 platealum 2024 t851 plate offers improved strength and stress corrosion resistance through T851 heat treatment, making it ideal for aircraft structures and high-load components.

- alum 2024 t351 platealum 2024 t351 plate provides high toughness and good dimensional stability, commonly used in aerospace frames, automotive parts, and industrial machinery.

alum 2024 bar and rod

alum 2024 bar and rod combine high strength and fatigue resistance, suitable for aerospace fittings, fasteners, and mechanical parts.

- Alum 2024 round bar: alum 2024 round bar delivers high performance for precision machining, often used in aircraft components, gears, and shafts.

- Alum 2024 flat bar: alum 2024 flat bar offers strength and easy machinability, widely applied in aerospace brackets, support beams, and tooling.

- Hex Bar alum 2024: Hex Bar alum 2024 is ideal for fasteners, connectors, and aerospace hardware requiring strength and wear resistance.

- Rectangle Bar alum 2024: Rectangle Bar alum 2024 provides structural strength for aerospace frames, marine fittings, and heavy-duty mechanical parts.

- Square Bar alum 2024: Square Bar alum 2024 is used in structural supports, machine frames, and aerospace applications requiring rigidity and durability.

- alum 2024 t3 baralum 2024 t3 bar offers an excellent balance of strength and workability, ideal for aerospace, defense, and high-stress applications.

- alum 2024 t4 baralum 2024 t4 bar is naturally aged for enhanced toughness, commonly used in aircraft structures and automotive performance parts.

- alum 2024 t851 baralum 2024 t851 bar provides superior dimensional stability and stress corrosion resistance, ideal for precision aerospace components.

- alum 2024 t351 baralum 2024 t351 bar combines high strength with good machinability, suited for aircraft fittings and heavy-duty machine parts.

- alum 2024 t851 round baralum 2024 t851 round bar delivers maximum strength and resistance to stress corrosion cracking, perfect for aerospace shafts and landing gear parts.

- alum 2024 t4 round baralum 2024 t4 round bar offers good toughness and fatigue resistance, suitable for automotive, aerospace, and marine equipment.

- alum 2024 t6 round baralum 2024 t6 round bar provides excellent mechanical properties and wear resistance, often used in aerospace structural members.

alum 2024 alclad

alum 2024 alclad features a corrosion-resistant cladding layer while maintaining core strength, ideal for aircraft skins and fuselage panels.

- alum 2024 t3 alcladalum 2024 t3 alclad combines high fatigue strength with superior corrosion protection, used in aerospace fuselage and wing structures.

- alclad alum 2024 t4alclad alum 2024 t4 offers balanced strength and corrosion resistance, perfect for structural and skin applications in aircraft.

Round Tube alum 2024

Round Tube alum 2024 is lightweight yet strong, making it suitable for aerospace frames, automotive roll cages, and structural assemblies.

alum 2024 extrusion

alum 2024 t3511 extrusion

alum 2024 t3511 extrusion delivers consistent mechanical properties and excellent machinability, used in aerospace structures, marine fittings, and high-performance engineering projects.

Al 2024 Composition

Al 2024 is a high-strength hard aluminum, belonging to the Al-Cu-Mg series of aluminum alloys, and is a typical representative of the 2XXX series aluminum alloys. Its main alloying elements are copper (Cu), magnesium (Mg), and manganese (Mn), with copper being the core strengthening element.

Chemical composition: Copper (Cu) 3.8-4.9%, Magnesium (Mg) 1.2-1.8%, Manganese (Mn) 0.3-0.9%, with the remainder being Aluminum (Al).

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Zr | Ti | Standard |

| 2024 | 0.50 | 0.50 | 3.8-4.9 | 0.30-0.90 | 1.20-1.80 | 0.10 | 0.25 | - | 0.15 | GB/AMS/EN |

2024 Aerospace Aluminum Sheet Plate Mechanical Properties

| Alloy | Temper | Direction | Thickness(mm) |

Tensile strength(mm) RM(Mpa) |

Yield strength RP0.2(Mpa) |

Breaking elongation A50% |

Standard |

| 2024 thick plate | T351 | LT | 6-102 | 460-495 | 320-340 | 12.5-21.5 | AMS-QQ-A-250/4 |

| 2024 thin plate | T4 | - | 0.3-3.5 | 430-450 | 280-310 | 18-21 |

GB/T380 EN485 ASTM B209 |

Machining Characteristics of 2024 Aerospace Aluminum Sheet Plate

When machining 2024 aluminum alloy, it is important to consider its work hardening characteristics, typically using cold working or hot working methods. Caution is needed during welding, as this alloy has relatively poor weldability, which may lead to a reduction in the strength of the welded joints.

2024 aluminum also has high strength and some heat resistance, making it suitable for working parts below 150°C. Its strength exceeds that of 7075 aluminum plates at temperatures above 125°C. It exhibits good formability in the solution-treated, annealed, and freshly quenched states, with significant strengthening effects from heat treatment, although the heat treatment process has strict requirements.

2024 Aluminum Sheet Plate Stock List

Is 2024 aluminum stronger than 6061?

Yes, 2024 aluminum alloy is generally stronger than 6061 aluminum alloy. 2024 aluminum alloy is a high-strength aerospace aluminum alloy commonly used in aerospace and military applications, known for its high tensile and fatigue strength. In contrast, 6061 aluminum alloy is a more common alloy with good corrosion resistance and machinability, suitable for various engineering applications, but with relatively lower strength.

What is the difference between 2024 and 7075 aluminum?

2024 aluminum alloy is often used in aerospace structures, wings, and aircraft frames that require high strength and good fatigue performance.

7075 aluminum alloy is suitable for aerospace, military, and high-performance sports equipment (such as bicycle frames and climbing gear) that demand extremely high strength.

What temperature should aluminum 2024 be used at?

2024 aluminum alloy is suitable for high-strength and high-temperature applications, but caution should be exercised when temperatures exceed 120°C to avoid reduced strength and performance. The operating temperature for 2024 aluminum alloy typically ranges from -50°C to 150°C. Within this temperature range, it maintains good mechanical properties and strength. However, beyond this range, particularly in high-temperature environments, the strength of 2024 aluminum may decrease.

You may also be interested in the following

-

2024 T4 Aircraft Aluminum Sheet Plate for Fuselage Skins

The 2024-T4 aluminum alloy used for the fuselage skin features high strength, good formability, and excellent plate shape and surface quality.

-

7150 7055 2024 Aluminum for Aircraft Wing Panel

7150, 7055, 2024 have high strength, high toughness, corrosion resistance and other properties, suitable for manufacturing wing skin wall panels, wing ribs and webs and other structural parts.

-

7055 2024 Aluminum Plate for Aircraft Seats

7055 and 2024 aluminum alloy profiles are commonly used materials for manufacturing aircraft seats and are widely used due to their excellent performance.

-

2024 Aerospace Aluminum for Engine Cowl Skins

2024 high-strength aluminum is used for engine cowling skins because of its strength-to-weight ratio and high-temperature resistance, providing protection and optimal airflow.

-

2024 7075 Aerospace Aluminum for Door Components

2024 and 7075 high-strength aluminum alloys are used in aircraft door components to ensure durability, deformation resistance, and safety.

-

2024, 7075, and 7475 Aerospace Aluminum for Wing Skins

2024, 7075, and 7475 combinations exhibit excellent strength and fatigue resistance, making them suitable for wing skins to withstand deformation under stress.

-

2024 7075 Aerospace Aluminum for Fuselage Frames

2024, 7075, and 7475 aluminum alloys are essential materials in aerospace engineering, particularly for fuselage frames. Their unique properties enable engineers to select the most appropriate alloy based on specific requirements for strength, weight, corrosion resistance, and fatigue performance.

-

2024 7050 7075 Aerospace Aluminum for Horizontal Tail Fittings

Alloys 2024, 7050, and 7075 provide the necessary strength and stiffness for horizontal tail components of aircraft, ensuring reliable control surface performance.