7055 vs 7075

7055 and 7075 aluminum alloys both belong to the 7000 series and are primarily composed of zinc. Due to their excellent strength-to-weight ratio, they are widely used in the aerospace and structural fields.

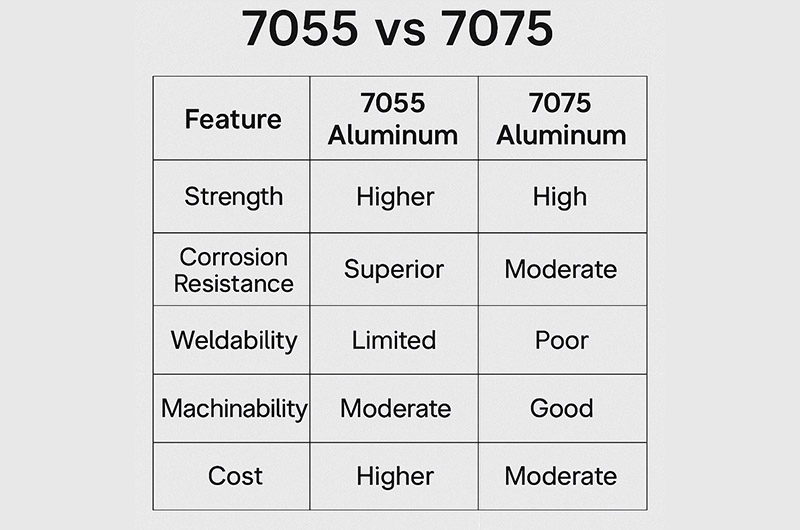

Both 7055 and 7075 are high-strength aluminum alloys suitable for demanding applications, but 7055 offers higher strength and corrosion resistance, making it an ideal choice for critical aerospace components. On the other hand, 7075 has a balanced combination of strength and machinability, making it suitable for various industries.

7055 vs 7075 Summary

| Feature | 7055 Aluminum | 7075 Aluminum |

| Strength | Higher | High |

| Corrosion Resistance | Superior | Moderate |

| Weldability | Limited | Poor |

| Machinability | Moderate | Good |

| Toughness | Moderate fracture toughness | Higher fracture toughness with stronger crack propagation resistance |

| Processability | High quenching sensitivity, prone to deformation | Zr element reduces quenching sensitivity, better process adaptability |

| Primary Use | Aerospace structures | Aerospace, automotive, sporting goods |

| Cost | Higher | Moderate |

7055 vs 7075 Corrosion Resistance and Stress Corrosion Cracking

7055 Corrosion Resistance and Stress Corrosion Cracking

- Due to the addition of zirconium, which stabilizes the microstructure, it exhibits excellent stress corrosion cracking (SCC) resistance.

- Maintains corrosion resistance even in thick-walled components (e.g., aerospace fuselage walls).

7075 Corrosion Resistance and Stress Corrosion Cracking

- Prone to stress corrosion in high-stress environments unless coated (e.g., clad with pure aluminum).

- T73 temper improves SCC resistance but reduces strength.

7055 vs 7075 Heat Treatment and Tempers

7055 Heat Treatment and Tempers

Common tempers: T7751, T77511 (overaged to relieve stress). Best performance can be achieved through Retrogression and Re-Aging (RRA).

7075 Heat Treatment and Tempers

Common tempers: T6 (peak strength), T651 (stress relieved), T73 (enhanced SCC resistance).

RRA treatment can restore T6 strength while improving corrosion resistance.

7055 vs 7075 Chemical Composition

7055 Aluminum Chemical Composition

- Compared with 7075, this alloy contains higher levels of zinc (7.6–8.4%), copper (2.0–2.6%), and zirconium (0.08–0.25%), with lower chromium content (≤0.04%). This composition enhances strength and fracture toughness.

- Primary elements: Zinc (main), Copper, Magnesium, Zirconium.

7075 Aluminum Chemical Composition

- Slightly lower contents of zinc (5.1–6.1%) and copper (1.2–2.0%), but higher chromium content (0.18–0.28%), which improves corrosion resistance. Magnesium (2.1–2.9%) also contributes to its strength.

- Primary elements: Zinc (main), Magnesium, Copper, Chromium.

| Element | 7055 (%) | 7075 (%) |

| Aluminum | 85.9 – 88.5 | Balance |

| Zinc (Zn) | 7.6 – 8.4 | 5.1 – 6.1 |

| Magnesium (Mg) | 1.8 – 2.3 | 2.1 – 2.9 |

| Copper (Cu) | 2.0 – 2.6 | 1.2 – 2.0 |

| Zirconium (Zr) | 0.08 – 0.25 | — |

| Chromium (Cr) | ≤ 0.04 | 0.18 – 0.28 |

| Others | ≤ 0.15 (total) | ≤ 0.15 (total) |

7055 vs 7075 Mechanical Properties

| Property | 7055-T7751 | 7075-T6 |

| Ultimate Tensile Strength | ~593 MPa | ~572 MPa |

| Yield Strength | ~524 MPa | ~503 MPa |

| Elongation at Break | 9–12% | ~11% |

| Fracture Toughness | ~24.2 MPa·√m | ~25 MPa·√m |

| Density | 2.86 g/cm³ | 2.81 g/cm³ |

- 7055: Possesses excellent compressive strength and fracture toughness, making it ideal for load-bearing structures.

- 7075: Offers higher tensile/yield strength in peak-aged tempers (e.g., T6), but lower elongation and toughness compared to 7055.

7055 vs 7075 Key Differences

- Strength: 7055 generally has higher tensile and yield strength than 7075, making it suitable for applications requiring extreme strength.

- Corrosion Resistance: 7055 exhibits superior stress corrosion cracking (SCC) resistance compared to 7075, especially in thicker sections.

- Weldability: Both alloys have limited weldability, but 7075 is more difficult to weld due to its tendency to crack.

- Machinability: 7075 is well-known for its good machinability, while 7055, being a newer alloy, has less available machining data.

7055 vs 7075 Applications

7055 Applications

- Aerospace: Compressive structures (e.g., fuselage frames, wing ribs).

- Thick plates (3-6 inches), where strength and crack resistance are critical.

7075 Applications

- Aerospace: Wing skins, landing gear, missile components.

- Consumer Goods: Used in bicycle frames, climbing gear, firearm components due to high strength-to-weight ratio.

| Alloy Grade | Application Field | Specific Parts/Components | Key Characteristics |

| 7055 | Aerospace | Aircraft wing skins | Ultra-high strength aluminum alloy with excellent corrosion and fatigue resistance, specifically designed for structurally critical parts, suitable for aerospace structures demanding high reliability. |

| Aircraft fuselage frames | |||

| High-strength structural components | |||

| 7075 | Aerospace | Aircraft parts (e.g., joints, reinforcements) | High strength, good machinability, widely used; although not as corrosion-resistant as 7055, its durability can be enhanced through surface treatments like anodizing, making it suitable for multiple applications. |

| Automotive | Gears and drive shafts | ||

| Sporting Goods | Bicycle components, climbing equipment, ski accessories, etc. |

7055 vs 7075 Machinability and Weldability

Both alloys have poor weldability and require special techniques (e.g., friction stir welding).

- 7055: Due to lower quenching sensitivity, it offers better machinability in thick-section components.

- 7075: Slightly easier to machine in the T6 temper, but tool wear is an issue.

7055 vs 7075 Cost and Availability

- 7055: More expensive due to its specialized aerospace applications and higher alloying elements (Zn, Zr).

- 7075: Broadly applicable and cost-effective, suitable for general high-strength applications.