7050 t7451 vs 7075 t6

Both 7050 and 7075 aluminum alloys belong to the Al-Zn-Mg-Cu series of ultra-high-strength aluminum alloys and are core structural materials in the aerospace field.

- 7075-T6 is renowned for its high strength and is one of the strongest commercially available alloys.

- 7050-T7451, while maintaining high strength, achieves superior stress corrosion resistance and fracture toughness through special heat treatment processes.

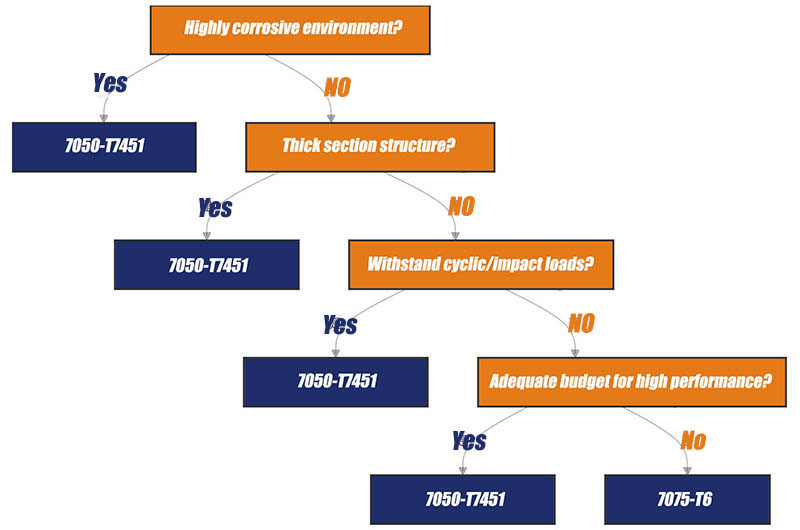

When deciding between 7050-T7451 and 7075-T6, factors such as application environment, structural characteristics, load characteristics, and budget should be comprehensively considered and systematically analyzed to achieve the optimal performance-to-cost balance.

- Material Performance Comparison: 7050-T7451 outperforms 7075-T6 in fracture toughness, fatigue strength, resistance to stress corrosion and exfoliation corrosion, and low-temperature impact performance; while 7075-T6 is slightly superior to 7050-T7451 in tensile strength, yield strength, and hardness.

- Product Forms and Specifications: 7075-T6 offers a wider variety of product forms, a broader specification range, and higher market maturity; while 7050-T7451 focuses more on high-performance and high-reliability applications, mainly supplying thick plates and large bars.

- Application Scenario Selection: For demanding, critical load-bearing structures, especially in corrosive environments or under cyclic load conditions, 7050-T7451 should be prioritized; for general high-strength structural applications, 7075-T6 is a more economical and mature choice.

- Field Application Characteristics: In primary load-bearing structures in aerospace, new energy vehicles, marine engineering, and other high-end fields, 7050-T7451 is playing an increasingly important role; while 7075-T6 maintains a dominant position in a wide range of fields such as general machinery, automotive manufacturing, and architectural decoration.

7050 T7451 vs 7075 T6 Chemical Composition

- 7050-T7451 has higher zinc and copper content, and uses zirconium (Zr) instead of chromium (Cr)

- 7075-T6 contains higher amounts of silicon and iron

- 7050-T7451 significantly improves exfoliation corrosion and stress corrosion resistance by optimizing the ratio of zinc, magnesium, and copper, and adding trace amounts of zirconium

7050-T7451 Chemical Composition

- Aluminum (Al): Balance

- Zinc (Zn): 5.7-6.7%

- Copper (Cu): 2.0-2.6%

- Magnesium (Mg): 1.9-2.6%

- Zirconium (Zr): 0.08-0.15% (replaces chromium to reduce quench sensitivity)

- Other elements: Silicon (Si ≤0.12%), Iron (Fe ≤0.15%), Manganese (Mn ≤0.10%), Titanium (Ti ≤0.06%)

7075-T6 Chemical Composition

- Aluminum (Al): Balance

- Zinc (Zn): 5.1-6.1%

- Copper (Cu): 1.2-2.0%

- Magnesium (Mg): 2.1-2.9%

- Chromium (Cr): 0.18-0.28%

- Other elements: Silicon (Si ≤0.40%), Iron (Fe ≤0.50%), Manganese (Mn ≤0.30%)

7050 T7451 vs 7075 T6 Mechanical Properties

Hardness and Strength Advantage: 7075-T6 has a slight edge in hardness and strength metrics, making it perform better in structural components that require higher load-bearing capacity.

| Mechanical Property | Comparative Analysis |

| Tensile Strength | The tensile strength of 7075-T6 is slightly higher than that of 7050-T7451, by about 3-5% |

| Yield Strength | The yield strength of 7075-T6 is also slightly higher than that of 7050-T7451, by about 3-7% |

| Hardness | The hardness of 7075-T6 is significantly higher than that of 7050-T7451, by about 11% |

| Elongation | The elongation of both alloys is basically the same, but that of 7050-T7451 is about 1% lower |

| Modulus of Elasticity | The modulus of elasticity of the two alloys is almost identical |

7050 T7451 vs 7075 T6 Corrosion Resistance

Corrosion Performance Summary: 7050-T7451 has a significant advantage in resistance to stress corrosion and exfoliation corrosion, making it particularly suitable for use in corrosive environments or in structures with long service life.

| Corrosion Resistance | 7050-T7451 | 7075-T6 | Comparative Analysis |

| Stress Corrosion Cracking (SCC) Resistance | Excellent, far superior to 7075-T6 | Average, high sensitivity to stress corrosion in T6 temper | The stress corrosion resistance of 7050-T7451 is significantly better than that of 7075-T6, which is one of its main advantages |

| Exfoliation Corrosion Resistance | Excellent | Moderate, needs surface treatment to improve | 7050-T7451 has significantly better exfoliation corrosion resistance than 7075-T6 |

| General Corrosion Resistance | Good, but bare material is prone to corrosion and requires anodizing or cladding | Good, but also requires surface treatment to improve corrosion resistance | After proper surface treatment, both have similar corrosion resistance, but in bare form 7050-T7451 is slightly better |

7050 T7451 vs 7075 T6 Machinability

Machinability Summary: 7075-T6 generally outperforms 7050-T7451 in machinability, especially in cutting and welding.

| Machining Property | 7050-T7451 | 7075-T6 | Comparative Analysis |

| Machinability (Cutting) | Good, but due to higher hardness, tool wear is faster | Excellent, good cutting performance, high machining surface quality | 7075-T6 has better machinability than 7050-T7451, especially in precision machining |

| Forgeability | Can be formed by forging, die forging, etc., but requires strict temperature control | Good forgeability, can be processed over a wider temperature range | 7075-T6 has slightly better forgeability than 7050-T7451 |

| Weldability | Not recommended for welding; welding may cause cracks, porosity, and weak joints | Weldability is limited, but slightly better than 7050-T7451 | Both alloys have poor weldability, but 7075-T6 is slightly better than 7050-T7451 |

| Heat Treatment Process Sensitivity | Low quench sensitivity, can maintain performance over a wider temperature range | High quench sensitivity, requires strict control of cooling rate | 7050-T7451 has a wider heat treatment process window and is easier to control |

7050 T7451 vs 7075 T6 Fracture Toughness and Fatigue Performance

Toughness and Fatigue Performance Summary: 7050-T7451 outperforms 7075-T6 in fracture toughness, fatigue strength, and low-temperature impact performance, making it perform better in structures subjected to dynamic loads and complex stress environments.

| Performance Index | Comparative Analysis |

| Fracture Toughness | The fracture toughness of 7050-T7451 is about 20% higher than that of 7075-T6 |

| Fatigue Strength | The fatigue strength of 7050-T7451 is about 18% higher than that of 7075-T6 |

| Impact Resistance | The low-temperature impact resistance of 7050-T7451 is significantly better than that of 7075-T6 |

Advantages and Disadvantages of 7050 T7451 vs 7075 T6

- 7050 T7451 is a high-performance, high-reliability ultra-high-strength aluminum alloy, particularly suitable for applications with extremely high requirements for strength, toughness, and corrosion resistance.

- 7075 T6 is a mature, reliable, and cost-effective general-purpose ultra-high-strength aluminum alloy, suitable for a wide range of high-strength structural applications.

| Property Category | 7050-T7451 Advantages | 7075-T6 Advantages | Relative Disadvantages |

| Mechanical Properties | Higher fracture toughness, better fatigue strength, excellent low-temperature impact performance | Higher tensile strength, higher yield strength, higher hardness | Slightly lower strength, slightly lower hardness |

| Corrosion Resistance | Excellent stress corrosion and exfoliation corrosion resistance | Average | Average corrosion resistance in bare form, requires surface treatment |

| Machinability | Low quench sensitivity, wide process window | Better cutting machinability, better forgeability, slightly better weldability | Slightly higher machining difficulty, faster tool wear |

| Other Characteristics | Good lightweight effect, high specific strength | High maturity, lower cost | Higher cost, relatively limited supply channels |

Product Forms and Specifications of 7050-T7451 and 7075-T6

Product Forms and Specifications of 7050-T7451 Aluminum Alloy

7050-T7451 Aluminum Plate Specifications

- Thickness: 6.35mm~203.20mm (0.25"~8")

- Width: 800mm~3500mm (31.5"~137.8")

- Length: 1000mm~27000mm (39.4"~1063")

- Typical thickness range: 3–6 inches (76.2–152.4mm) is the main thickness range for aerospace applications

- Special specifications: Ultra-thick plates in the 20–260mm thickness range are also available

7050-T7451 Aluminum Bar Specifications

- Diameter: 1.0–400mm (0.039"–15.75")

- Length: up to 6000mm (236.2")

- Typical diameter range: Mainly used for large structural parts with diameters above Φ250mm

Other Product Forms of 7050-T7451 Aluminum

- Extrusions: Structural parts with complex cross-sections can be produced by extrusion processes

- Forgings: Suitable for critical parts subjected to high stress, such as aircraft landing gear components

- Precision machined parts: Supports high-precision CNC machining, tolerances up to 0.005mm

Product Forms and Specifications of 7075-T6 Aluminum Alloy

7075-T6 Aluminum Plate Specifications

- Thickness: 0.3mm–500mm (0.012"–19.69")

- Width: Standard widths of 1000mm, 1220mm, 1250mm, 1500mm, etc., up to a maximum of 3500mm

- Length: Standard lengths of 2000mm, 2400mm, 2500mm, etc., up to a maximum of 6000mm

- Special specifications: Ultra-wide, ultra-long, or ultra-thin plates can be customized

7075-T6 Aluminum Bar Specifications

- Diameter: 3mm–550mm (0.118"–21.65")

- Length: Standard lengths of 2500mm, 4000mm, etc., can be cut according to customer requirements

- Special specifications: Ultra-large diameter bars up to 700mm

Other Product Forms of 7075-T6 Aluminum

- Wire products: Diameter 0.1mm–20mm, customizable length

- Extrusions: Widely used in various structural parts, capable of producing complex cross-sections

- Forgings: Suitable for high-stress components such as aircraft landing gear structures

- Precision machined parts: Supports high-precision machining, suitable for aerospace precision components

Applications of Product Forms and Specifications

Characteristics of 7050-T7451 Product Forms

- Mainly supplies thick plates and large bars, suitable for manufacturing large structural parts

- Extrusions and forgings are mostly used in high-demand fields such as aerospace

- Specification range is relatively narrow, focusing more on high-performance, high-reliability applications

Characteristics of 7075-T6 Product Forms

- The most diverse product forms and widest specification range, meeting various application needs

- Full series supply of plates, bars, tubes, wires, etc., with high market maturity

- Adequate supply of small and medium-sized products, with relatively stable prices

Product Selection Recommendations

- For large thick-section structural parts, give priority to 7050-T7451 thick plate products due to their low quench sensitivity, which maintains uniform properties in thick sections

- For structural parts requiring complex shapes, 7075-T6 extrusions or forgings may be a better choice due to better machinability

- For components requiring high precision and high surface quality, 7075-T6 may be more suitable due to its superior cutting machinability

Application Selection Guide for 7050-T7451 and 7075-T6

Recommendations Based on Application Environment

High Stress Corrosion Environment

Preferred choice: 7050-T7451

- Reason: Excellent stress corrosion and exfoliation corrosion resistance, especially suitable for marine, humid, or chemical environments

- Typical applications: Offshore platform structures, chemical equipment, coastal building structures, etc.

Dry or Low Corrosion Environment

Consider: 7075-T6

- Reason: In such environments, the corrosion resistance of 7075-T6 is sufficient, and it offers lower cost and higher strength

- Typical applications: Building structures in inland areas, general industrial machinery components, etc.

Low Temperature or Extreme Cold Environment

Preferred choice: 7050-T7451

- Reason: Impact toughness reaches 180J/cm² at -60°C, far superior to 7075-T6

- Typical applications: Polar equipment, low-temperature containers, infrastructure in cold regions, etc.

High Temperature Environment

Choose with caution

- Reason: Both alloys are not suitable for long-term use above 150°C

- Alternative suggestion: Consider 2XXX series aluminum alloys or high-temperature alloys

Recommendations Based on Structural Characteristics

Thick Section Structural Parts

Preferred choice: 7050-T7451

- Reason: Lower quench sensitivity allows good strength and toughness to be maintained in thicker sections

- Typical applications: Large aircraft wing beams, fuselage frames, heavy machinery structural components, etc.

Thin-Walled Structural Parts

Consider: 7075-T6

- Reason: Better machinability, making it easier to achieve precise machining of thin-walled structures

- Typical applications: Aircraft skin, instrument housings, automobile body panels, etc.

Complex-Shaped Structural Parts

Preferred choice: 7075-T6

- Reason: Better cutting machinability and forging performance, making complex shapes easier to process

- Typical applications: Complex molds, special-shaped structural components, precision machinery parts, etc.

Structural Parts Subjected to Cyclic Loads

Preferred choice: 7050-T7451

- Reason: Higher fatigue strength and fracture toughness, better able to withstand cyclic stresses

- Typical applications: Bridge structures, vibrating equipment components, vehicle suspension systems, etc.

Recommendations Based on Industry Sectors

Aerospace Sector

- Primary load-bearing structures: Prefer 7050-T7451, such as aircraft wing beams, fuselage frames, landing gear components, etc.

- Non-primary load-bearing structures: Consider 7075-T6, such as interior structures, non-load-bearing skin, etc.

- High-temperature components: Neither is suitable; consider titanium alloys or composite materials

Automotive Manufacturing Sector

- High-performance racing cars: Prefer 7050-T7451 for chassis structures, suspension components, etc.

- Regular passenger cars: Prefer 7075-T6 for bumper beams, chassis components, seat frames, etc.

- Armored vehicles: 7050-T7451 for armor plates, improving ballistic resistance by 3 times and reducing weight by 25%

Military Equipment Sector

- Armor protection: Prefer 7050-T7451 for armor plates, bulletproof structures, etc.

- Weapon systems: Depending on specific requirements, use 7050-T7451 for high-demand components and 7075-T6 for general components

- Aerospace weapons: Prefer 7050-T7451, such as missile casings, etc.

Selection Recommendations Based on Cost-Performance Balance

High-Performance Priority Scenarios

Recommended Choice: 7050-T7451

- Reason: Superior performance in key indicators (such as stress corrosion resistance, fracture toughness, and fatigue strength)

- Applicable Situations: Safety-critical components, systems with high reliability requirements, and important structures in long-term service

Cost-Priority Scenarios

Recommended Choice: 7075-T6

- Reason: Lower cost, widely available supply channels, and high maturity

- Applicable Situations: Non-critical structural components, mass-produced general structural parts, and applications sensitive to cost

Balanced Performance and Cost Scenarios

Recommended Choice: Use 7050-T7451 for critical parts and 7075-T6 for non-critical parts, depending on specific application requirements

- Reason: Achieves optimal configuration of performance and cost

- Applicable Situations: Large complex systems, hybrid structure designs, etc.