What is 7050 aluminum used for?

As a high-performance Al-Zn-Mg-Cu alloy, 7050 aluminum alloy, with its high strength, high toughness, resistance to stress corrosion cracking, heat treatability, and lightweight characteristics, is widely used in aerospace, military equipment, sports equipment, marine, and many other fields.

- Aerospace field: Mainly used in the form of pre-stretched thick plates, forgings, and extrusions for key load-bearing components such as aircraft wing beams, fuselage frames, and bulkheads.

- Military equipment field: Mainly used in the form of thick plates, forgings, and tubes for armor plates of armored vehicles, weapon system brackets, and ship structural components.

- Sports equipment field: Mainly used in the form of tubes, forgings, and bars for bicycle frames, golf club heads, and mountaineering equipment.

- Marine field: Mainly used in the form of thick plates, extrusions, and tubes for hull structures, deck systems, and bulkheads.

Applications in the Aerospace Field

The aerospace industry is the most extensive and critical application field for 7050 aluminum alloy, mainly because its high strength, lightweight, fatigue resistance, and corrosion resistance perfectly meet the stringent requirements of aerospace structural components.

As a core material for aircraft structural components, 7050 aluminum alloy is widely used to manufacture key load-bearing parts such as wing beams, fuselage frames, wing ribs, and bulkheads.

Forms of 7050 Aluminum Products in the Aerospace Field

- Pre-stretched thick plate 7050-T7451 pre-stretched thick plate is one of the most widely used product forms in the aerospace field, mainly for manufacturing aircraft wing skins, fuselage frames, and bulkheads.

- Forgings 7050 aluminum alloy forgings, especially die forgings, are used to manufacture high-strength joints, landing gear components, and flap tracks for aircraft.

- Extrusions 7050 aluminum alloy extrusions are mainly used to manufacture aircraft stringers, stiffeners, and window frames.

- Bars and wires 7050 aluminum alloy bars and wires are mainly used to manufacture bolts, rivets, and other fasteners for aircraft.

Other Fields Where 7050 Aluminum is Used

Applications in the Military Equipment Field

One of the most notable applications of 7050 aluminum alloy in the military field is in the armor systems of armored vehicles. Due to its high strength and excellent impact resistance, 7050 aluminum alloy is widely used to manufacture protective plates, turrets, and ballistic structures for armored vehicles.

Performance Advantages

Compared with traditional armor materials, 7050 aluminum alloy offers higher ballistic performance and lighter weight. Reports indicate that armor plates made from 7050 aluminum alloy can improve ballistic performance by up to 3 times while reducing weight by 25%.

Product Forms in the Military Equipment Field

- 7050 aluminum alloy thick plate

- 7050 aluminum alloy forgings

- 7050 aluminum alloy extrusions

- 7050 aluminum alloy tubes

Applications in the Sports Equipment Field

7050 aluminum alloy is particularly prominent in the bicycle manufacturing field, especially in high-end racing bicycles and mountain bikes for frames, handlebars, and other key components.

Specific Applications

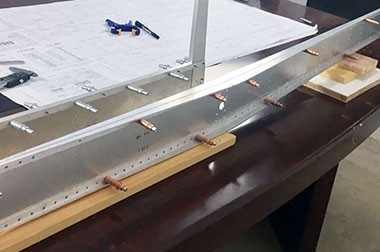

In bicycle frame manufacturing, 7050 aluminum alloy is mainly used in the form of tubes and forgings. Tubes are used to manufacture the main structural parts of the frame, while forgings are used for joints and mounting bases that require high strength.

Golf Equipment

7050 aluminum alloy is also widely used in the golf equipment field, mainly for manufacturing golf club heads and shafts. Golf club heads need to withstand enormous impact forces at the moment of hitting the ball, while also providing good elasticity and feel.

Other High-performance Sports Equipment

- Mountaineering equipment: trekking poles, ice axes, and climbing gear

- Hockey equipment: hockey sticks and ice hockey sticks

- Racket sports equipment: tennis rackets, badminton rackets, and squash rackets

- Sports training equipment: jump rope handles, etc.

Applications in the Marine Field

In the marine field, 7050 aluminum alloy is mainly used in hull structures, deck systems, and bulkheads. These areas require materials with high strength, good corrosion resistance, and lightweight characteristics.

Marine Power and Propulsion Systems

7050 aluminum alloy is also used in marine power and propulsion systems, mainly for manufacturing engine brackets, drive shafts, and propeller components. These parts require materials with high strength and good corrosion resistance.

Marine Interior Decoration and Furniture

7050 aluminum alloy is also used in marine interior decoration and furniture systems, mainly in the form of plates and extrusions. These products are usually surface-treated to improve corrosion resistance and aesthetics.

Characteristics of 7050 Aluminum

- High strength and lightweight Tensile strength can reach 500-550 MPa, yield strength about 450-490 MPa, which is close to or even exceeds that of ordinary carbon steel, while its density is only about 1/3 that of steel.

- Excellent stress corrosion resistance and fatigue performance Exhibits outstanding resistance to stress corrosion cracking (SCC) and high fatigue performance, especially in the T7451 heat treatment condition, where its exfoliation corrosion resistance and stress corrosion fracture resistance are particularly remarkable.

- Good heat treatment and processing performance A heat-treatable strengthening alloy, its mechanical properties can be significantly improved through solution treatment and aging. Supports forging, rolling, extrusion, CNC precision machining, and other processing methods.

- Low-temperature toughness and fracture toughness Maintains good toughness in low-temperature environments, with high fracture toughness. Compared with 7075 aluminum alloy, it has lower quenching sensitivity and better thick-section strength retention capability.