6082 T651 Aluminum

6082 T651 aluminum alloy is an enhanced version of the 6082 alloy, which undergoes stress-relieving treatment based on the T6 heat treatment. The key feature of the T651 state is the elimination of internal stresses generated during processing, which increases stability in subsequent processing and reduces the risk of deformation or cracking.

6082 T651 is a medium-strength, heat-treatable aluminum-magnesium-silicon (6xxx series) alloy, known for its excellent strength, corrosion resistance, and machinability. This alloy is subjected to solution heat treatment, stress relief through stretching, and then artificially aged to the T651 condition. Its typical ultimate tensile strength is about 300 MPa, with a yield strength higher than 255 MPa, an elongation of approximately 9%, and a Brinell hardness close to 91 HB. Its chemical composition is balanced, with controlled silicon, magnesium, and manganese content, optimizing the grain structure and strength, while maintaining good ductility and weldability.

6082 T651 is renowned for its structural integrity, excellent machinability, and corrosion resistance. The "T651" designation indicates that the material has undergone solution heat treatment, stress relief through stretching, and artificial aging treatment, which improves dimensional stability and reduces residual stresses during processing.

6082 Aluminum T651 Heat Treatment Process

- Solution Heat Treatment: During this stage, the 6082 aluminum alloy is heated to an appropriate temperature to fully dissolve the solute elements into the matrix, forming a uniform solid solution. This process increases the strength and hardness of the alloy.

- Stress-Relieving Treatment: On the basis of the T6 state, the 6082 aluminum alloy is stretched to a certain amount to eliminate internal stresses caused by heat treatment, processing, or deformation. This treatment ensures the alloy maintains a stable shape in subsequent processing.

- Artificial Aging: By controlling temperature and time, the solute elements in the 6082 aluminum alloy will further precipitate, further strengthening the material's mechanical properties.

6082 T651 Aluminum Mechanical Properties

- Tensile Strength: The tensile strength of 6082 T651 aluminum alloy is similar to that of the T6 state, typically ranging from 310 to 400 MPa, depending on the shape and size of the material.

- Yield Strength: The yield strength typically ranges from 275 to 350 MPa.

- Hardness: The hardness in the T651 state is similar to that in the T6 state, but due to the elimination of internal stresses, the T651 alloy exhibits better stability and shape retention. The hardness generally ranges from 95 to 115 HB.

- Ductility and Formability: The T651 aluminum alloy offers good ductility and formability, especially in precision machining, where it can maintain excellent dimensional accuracy and shape stability.

6082 T651 Aluminum Characteristics

- Stress Relief Stability: The T651 state significantly enhances the material's stability by eliminating internal stresses generated during processing. This makes 6082 T651 aluminum alloy excel in complex and high-precision machining, greatly reducing the risk of deformation and cracking.

- Processing Accuracy: With the removal of internal stresses, the dimensional accuracy of T651 aluminum alloy is superior to the T6 state, making it particularly suitable for applications requiring strict tolerances. It can better maintain shape and dimensions during processing, avoiding instability.

- Excellent Weldability and Corrosion Resistance: Like the T6 state, T651 aluminum alloy retains good weldability and corrosion resistance, making it ideal for structural components in industrial and transportation applications.

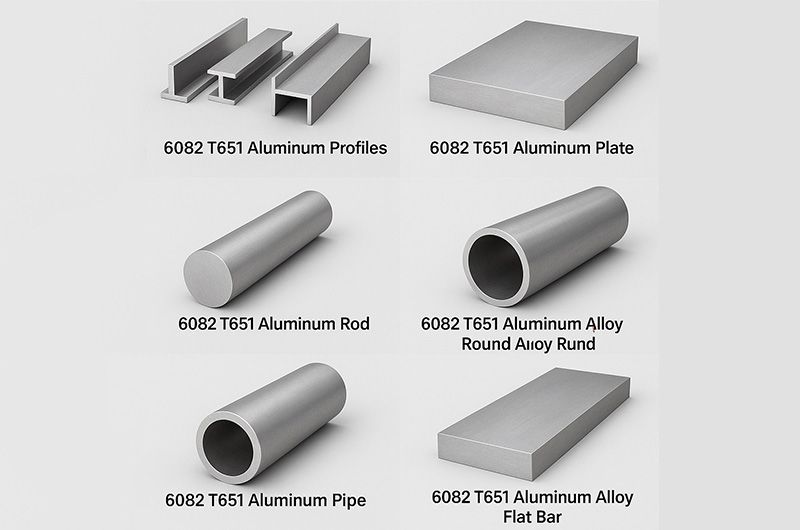

Product Forms and Specifications of 6082 T651 Aluminum Alloy

- 6082 T651 aluminum plates: Flat surface and precise thickness, suitable for various structural components and decorative parts

- 6082 T651 aluminum bars/round bars: Solid material with a circular cross-section, suitable for applications requiring high-strength support or rotating parts

- 6082 T651 aluminum tubes: Including seamless aluminum tubes and welded tubes, suitable for fluid transportation, structural support, and decorative purposes

- 6082 T651 aluminum profiles: Various cross-sectional shapes produced through extrusion, widely used in building structures and machinery manufacturing

- 6082 T651 aluminum wires/rods: Small-diameter round materials, mainly used for special manufacturing processes and small structural parts

6082 T651 Aluminum Product Forms

| Product Form | Detailed Description |

| 6082 T651 Aluminum Profiles | 6082 T651 aluminum profiles are widely used in various extrusion processes, suitable for manufacturing structural parts, frames, and supports, offering good strength, stability, and processing performance. They are commonly applied in construction, transportation, and mechanical equipment, especially for large-span support and frame structures. |

| 6082 T651 Aluminum Plate | 6082 T651 aluminum plate features high strength, excellent dimensional accuracy, and stability, making it suitable for manufacturing structural components, panels, and load-bearing parts. It performs exceptionally well in applications where high strength and precision are required, such as in aerospace, precision machinery, and the automotive industry. |

| 6082 T651 Aluminum Tube | 6082 T651 aluminum tubes are used in hydraulic systems, structural supports, and transportation and mechanical equipment, offering good strength and corrosion resistance. They are commonly applied in situations that require high performance, long service life, and high strength. |

| 6082 T651 Aluminum Rod | 6082 T651 aluminum rods are widely used for manufacturing high-precision mechanical parts and tools, ideal for precision machining, industrial equipment, and automotive parts. They provide excellent machining performance and corrosion resistance, making them ideal for components with high strength and precision requirements. |

| 6082 T651 Aluminum Pipe | 6082 T651 aluminum pipes are suitable for structural supports in construction, mechanical, and transportation industries. They perform excellently in large-span structures and applications that demand high strength and stability, making them an ideal choice for structural components. |

| 6082 T651 Aluminum Alloy Round Bar | 6082 T651 aluminum alloy round bars are commonly used for machining high-strength and precision-required components, ideal for mechanical processing and manufacturing high-strength structural parts. They are widely used in aerospace, automotive, and precision equipment production. |

| 6082 T651 Aluminum Alloy Plate | 6082 T651 aluminum alloy plates are suitable for manufacturing thick-plate structural components, with good corrosion resistance, mechanical properties, and machinability. They are commonly used in machinery, transportation equipment, and applications requiring high strength and stability. |

| 6082 T651 Aluminum Alloy Flat Bar | 6082 T651 aluminum alloy flat bars are used in various electronic, electrical, and precision equipment applications. They meet the needs for precision machining and high-strength requirements, making them ideal for high-performance and high-precision applications. |

Product Specifications of 6082 T651 Aluminum Alloy

Specifications for 6082 T651 Aluminum Plates

- Thickness range: 0.5 mm to 300 mm

- Width range: 500 mm to 2650 mm

- Length range: 500 mm to 12000 mm

- Standard sizes: 1250 mm × 2500 mm, 1500 mm × 3000 mm, 1600 mm × 3000 mm, etc.

Specifications for 6082 T651 Aluminum Bars

- Diameter range: 2.0 mm to 500 mm

- Length range: Usually supplied in standard lengths, but can also be customized according to customer requirements; common length is within 6 meters

- Precision grades: Available in standard precision and high precision

Specifications for 6082 T651 Aluminum Tubes

- Outer diameter range: 8 mm to 300 mm

- Wall thickness range: 1 mm to 50 mm

- Length range: 10 mm to 5000 mm

- Shapes: Round tubes, square tubes, rectangular tubes, and other special cross-sectional shapes

Specifications for 6082 T651 Aluminum Profiles

- Open profile dimensions: Minimum 4 mm × 3 mm, maximum 850 mm × 50 mm

- Closed profile dimensions: Minimum 6.35 mm × 1 mm, maximum 573 mm × 10 mm

- Length range: Standard length is usually 6000 mm, with a maximum length of up to 28 meters for extra-long profiles

6082 T651 Aluminum Applications

| Application Area | Description | Product Forms |

| Transportation Framework and Structural Components | 6082 T651 aluminum alloy is widely used in the framework and structural components of transportation vehicles due to its excellent strength and stability. It is particularly used in the automotive, rail, aerospace, and maritime industries, providing a balance of strength and lightweight properties. Thanks to its excellent corrosion resistance, T651 aluminum alloy can withstand extreme weather conditions and prolonged use while providing sufficient strength to bear various loads in transportation vehicles. T651 aluminum alloy is commonly used to manufacture key structural parts such as frames, fuselages, supports, and hulls, improving overall durability and safety. | 6082 T651 aluminum profiles, 6082 T651 aluminum plates, 6082 T651 aluminum tubes, 6082 T651 aluminum bars |

| Precision Mechanical Components | 6082 T651 aluminum alloy is also widely used in high-precision mechanical parts and components. Its good mechanical properties and high strength make it suitable for demanding dimensional tolerance requirements, ensuring the stability and reliability of precision machinery. For example, T651 aluminum alloy is commonly used in precision tools, machine tool components, and structural parts in automation equipment. Its surface can undergo anodizing treatment, providing additional wear resistance and corrosion protection. | 6082 T651 aluminum plates, 6082 T651 aluminum bars, 6082 T651 aluminum profiles, 6082 T651 aluminum tubes |

| Building Support Structures | In the construction industry, 6082 T651 aluminum alloy is widely used in load-bearing structures and support frameworks due to its high strength and stability. It provides excellent performance in construction projects requiring high structural load-bearing capacity and stability. For example, T651 aluminum alloy is used in external support frames, staircases, platforms, and roof structures. Additionally, its lightweight characteristics help reduce the overall weight of the building and improve its seismic resistance. | 6082 T651 aluminum profiles, 6082 T651 aluminum plates, 6082 T651 aluminum tubes |

| Large Aluminum Profiles | 6082 T651 aluminum alloy is suitable for manufacturing large aluminum profiles, which are widely used in transportation vehicles, buildings, industrial equipment, and other fields. For large aluminum profiles with strict dimensional accuracy requirements, T651 aluminum alloy provides an excellent solution. Due to its excellent extrusion properties and high strength after heat treatment, T651 aluminum alloy ensures high precision and strength when manufacturing large aluminum profiles. For example, in large construction projects, T651 aluminum alloy profiles are commonly used in frame structures and large-span support structures. | 6082 T651 aluminum profiles, 6082 T651 aluminum plates, 6082 T651 aluminum tubes, 6082 T651 aluminum bars |

Advantages of 6082 T651 Aluminum

Outstanding Machining and Welding Performance

6082 T651 aluminum alloy exhibits excellent performance in machining and welding, making it suitable for CNC lathes and high-speed milling, with smooth machined surfaces. This alloy has good weldability, especially suitable for arc welding and TIG welding, with good deformation control after welding.

Excellent Corrosion Resistance

6082 T651 aluminum alloy demonstrates excellent corrosion resistance in natural environments, maintaining stability even in humid and marine environments, and is not prone to rust or corrosion. Compared with the 6061 aluminum alloy of the same series, 6082 offers better corrosion resistance.

Cost and Cost-Effectiveness Advantages

Although the cost of 6082 is slightly higher than that of commonly used aluminum alloys such as 6061 and 6063, its overall performance advantages make it more cost-effective in many applications. As part of aluminum-based materials, 6082 aluminum alloy has a very high recycling value and reusability rate.

| Advantage | Detailed Description |

| Stress Relief | After undergoing the T651 heat treatment, the internal stresses of 6082 T651 aluminum alloy are effectively relieved. This process, which involves annealing the alloy, eliminates the residual stresses that may occur during thermal processing, cold working, or extrusion. By removing these internal stresses, issues such as deformation, cracking, and warping are greatly reduced, thereby enhancing the stability and machinability of the finished product. Especially during subsequent processing or assembly, the risk of deformation due to stress is minimized, ensuring that the final product is more accurate and reliable in terms of dimensions and shape. |

| High Dimensional Accuracy | In the T651 state, 6082 T651 aluminum alloy offers excellent dimensional accuracy and good processing stability. Due to the stress-relieving treatment, the likelihood of deformation is reduced, ensuring high-precision cutting and shaping during machining. It is particularly suitable for applications with strict dimensional tolerance requirements, such as precision mechanical components, aerospace equipment, and high-precision tools. The processed parts not only have accurate dimensions but also a smooth surface, reducing the complexity of subsequent processing and improving production efficiency. |

| Stronger Stability | In the T651 state, the internal stresses of 6082 aluminum alloy are eliminated, making its mechanical properties more stable. This stability is crucial for maintaining structural integrity during long-term use, especially in dynamic load and high-stress environments. Compared to untreated aluminum alloys, T651 aluminum alloy exhibits superior fatigue resistance, ensuring a longer service life under repeated loading and vibration. Moreover, during processing, the stability of T651 aluminum alloy reduces the impact of thermal expansion and contraction, further improving production accuracy. |

| Wide Adaptability | The advantage of 6082 T651 aluminum alloy lies in its adaptability to a wide range of applications, especially in situations requiring high strength, good machinability, and high stability. It offers excellent mechanical strength and corrosion resistance, making it ideal for use in industries such as aerospace, automotive, machinery manufacturing, construction, and industrial equipment. Whether in the manufacturing of high-strength transportation vehicle frames, precision mechanical parts, or in the construction of support structures and industrial equipment, 6082 T651 aluminum alloy provides an excellent material choice. Its outstanding machinability ensures high production efficiency and precision in various complex machining processes, making it widely used in complex structural components that require precision cutting, forming, and welding. |

6082 T651 aluminum alloy plays a crucial role in many industries due to its excellent stability, high machining accuracy, and strength. It is particularly suitable for high-end applications that demand strict dimensional accuracy and shape retention.

6082 T651 Aluminum Composition and Properties

| Element | Composition(%) |

| Si | 0.7-1.3 |

| Fe | 0.50 |

| Cu | 0.10 |

| Mn | 0.40-1.00 |

| Mg | 0.06-1.20 |

| Cr | 0.25 |

| Zn | 0.20 |

| Ti | 0.10 |

| Al | Remainder |

6082 T651 Aluminum Mechanical Properties

| Property | Value |

| Brinell Hardness | 91 |

| Elastic Modulus (GPa) | 69 |

| Elongation at Break (%) | 6.3 |

| Fatigue Strength (MPa) | 94 |

| Poisson's Ratio | 0.33 |

| Shear Modulus (GPa) | 26 |

| Shear Strength (MPa) | 190 |

| Tensile Strength: Ultimate (UTS, MPa) | 320 |

| Tensile Strength: Yield (MPa) | 270 |

6082 T651 Aluminum Thermal Properties

| Property | Value |

| Latent Heat of Fusion (J/g) | 410 |

| Maximum Temperature: Mechanical (°C) | 170 |

| Melting Completion (Liquidus, °C) | 650 |

| Melting Onset (Solidus, °C) | 580 |

| Specific Heat Capacity (J/kg-K) | 900 |

| Thermal Conductivity (W/m-K) | 160 |

| Thermal Expansion (µm/m-K) | 23 |

6082 T651 Aluminum Electrical Properties

| Property | Value |

| Electrical Conductivity: Equal Volume (% IACS) | 42 |

| Electrical Conductivity: Equal Weight (% IACS) | 140 |

6082 T651 Aluminum Corrosion Resistance and Surface Finish

6082-T651 has excellent atmospheric and fresh water corrosion resistance. Due to its higher manganese content and controlled iron and zinc levels, its performance is superior to many other 6000 series alloys. It is easy to anodize, forming a uniform protective oxide layer suitable for both decorative and functional coatings.

- Corrosion resistance is superior to common aluminum alloys, making it suitable for anodizing, coating, and other surface treatments.

- Balanced cold/hot working performance, suitable for rolling, forging, extrusion, and other processes.

6082 T651 Aluminum Manufacturing and Processing

This alloy has excellent machinability, and T651 temper plates are typically the preferred choice for parts that require tight tolerances and fine surface finishes. Welding (GTAW, GMAW) can be performed after post-weld aging, but the joint strength may be slightly lower than the base material. It can be extruded, cold-formed, and forged, but it is not suitable for casting.

6082 T651 Aluminum Heat Treatment Process

The T651 temper process involves three key steps:

- Solution Heat Treatment: Heating to dissolve alloying elements uniformly.

- Stress Relief: Stretching to eliminate internal stresses and improve processing stability.

- Artificial Aging: Aging at a controlled temperature to precipitate strengthening phases.

This process enhances dimensional accuracy and reduces the risk of warping in precision applications.

6082 T651 Aluminum vs. Similar Alloys

- 6082 vs. 6061: 6082 has higher strength and hardness, but slightly lower ductility. They are generally interchangeable, but 6082 is the preferred choice for structural applications.

- T651 vs. T6: T651 has a stress relief process, offering better dimensional stability than T6.

6082 T651 Aluminum Limitations

- Brittleness: Compared to other 6000 series alloys, it has lower ductility.

- Extrusion challenges: Difficult to form thin-walled or complex shapes.

6082 T651 Aluminum Standards and Equivalent Standards

- EN Standard: EN AW-6082, DIN 3.2315.

- ISO: AlSi1MgMn.

- ASTM: AA6082, A96082.

6082 T6 vs. T651 Temper Comparison

| Characteristics | T6 | T651 |

| Processing Steps | Solution + Direct Aging | Solution + Stretching + Aging |

| Internal Stresses | Higher | Significantly Reduced |

| Flatness | Average | Better |

| Suitable Applications | General Structural Parts | High-Precision Instrument Base Materials |

6082 T651 offers robust mechanical properties, excellent corrosion resistance, and machinability, making it the material of choice for high-performance structural and machining applications.