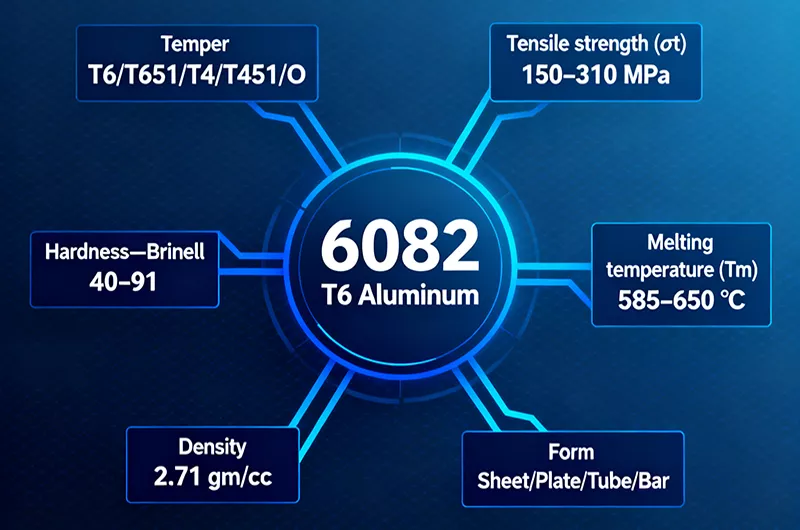

6082 T6 Aluminum Properties

The 6082-T6 aluminum alloy features a balance of strength, weldability, and corrosion resistance. "T6" indicates that it has undergone solution heat treatment followed by artificial aging, significantly enhancing its mechanical properties. Due to its high strength, durability, and light weight, it is widely used in the construction, transportation, and marine industries.

6082-T6 is a high-strength, corrosion-resistant aluminum alloy with excellent machinability, often replacing 6061 aluminum alloy in high-demand applications.

- Grade: 6082

- Temper: T6

- T6 temper represents "solution heat treated followed by artificial aging." This is a process that significantly increases the alloy's strength and hardness through heat treatment.

- Specific process: the alloy is heated to a high temperature (solution treatment), rapidly cooled (quenching), and then maintained at a certain temperature for a period of time (artificial aging).

- Advantages: high strength, good corrosion resistance, weldable, easy to machine.

- Disadvantages: forming ability in T6 temper is average; strength in the heat-affected zone after welding drops significantly.

- Recommendation: when design requires weight reduction and higher strength, 6082-T6 is a better choice than 6061-T6, especially for load-bearing structural parts and components under dynamic loads.

6082-T6 is an aluminum alloy that prioritizes strength while considering machinability and corrosion resistance. Its performance is between "general-purpose 6061" and "high-strength 7 series," filling the gap for "medium strength + high cost-effectiveness" applications. It is particularly suitable for lightweight load-bearing structural scenarios and is one of the key materials in industry for "aluminum replacing steel."

6082 T6 Aluminum Properties and Advantages

- High strength (core advantage): Among 6-series aluminum alloys, 6082-T6 has very high strength, with yield strength and tensile strength higher than the common 6061-T6.

- Excellent corrosion resistance: It has good resistance to atmospheric and seawater corrosion, similar to 6061 alloy. Suitable for a variety of environmental conditions.

- Good machinability: In the T6 temper, 6082 aluminum alloy is easy to perform turning, milling, drilling, and other machining processes, with good surface finish after machining.

- Moderate formability: Its formability (such as bending and stretching) is best in the "O" temper (annealed state). In T6 temper, due to high strength, formability is limited, requiring greater force for bending and specific bending radius requirements.

- Excellent weldability: Can be welded using common methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding.

Note: After welding, the strength of the heat-affected zone (HAZ) may decrease due to overheating, typically returning to the soft level of the "O" temper (annealed state). For critical structures, post-weld heat treatment (T6 treatment) may be required to restore overall strength.

6082 T6 Aluminum Properties - Chemical Composition

Typical Range (Weight Percent)

- Silicon (Si): 0.7 – 1.3%

- Magnesium (Mg): 0.6 – 1.2%

- Manganese (Mn): 0.4 – 1.0%

- Iron (Fe): 0.0 – 0.5%

- Chromium (Cr): 0.0 – 0.25%

- Zinc (Zn): 0.0 – 0.2%

- Titanium (Ti): 0.0 – 0.1%

- Copper (Cu): 0.0 – 0.1%

- Aluminum (Al): Remainder (95.2 – 98.3%)

6082 Aluminum Properties - Mechanical Properties (T6 Temper)

Strength Performance: The highest strength among 6000 series aluminum alloys, suitable for high-stress applications (e.g., bridges, cranes)

Heat Treatment Characteristics: T6 temper is achieved through solution heat treatment followed by artificial aging, significantly improving mechanical properties, with no cold working after processing.

- Yield Strength: 250 – 260 MPa (depends on product shape and size)

- Tensile Strength (Ultimate): 295 – 310 MPa

- Elongation at Break: 6–10% (A50 mm: ~6% for larger bars, up to 10% for thinner profiles)

- Brinell Hardness: ~95 HB

- Fatigue Strength: ~95 MPa

- Shear Strength: ~220 MPa

- Modulus of Elasticity (Tensile): ~69 GPa

- Shear Modulus: ~26 GPa

- Poisson's Ratio: ~0.33

6082 T6 Aluminum Properties - Physical and Thermal Properties

- Density: 2.70 g/cm³ (2700 kg/m³)

- Melting Point: Solidus ≈580 °C; Liquidus ≈650 °C

- Thermal Conductivity: 160–180 W/m·K

- Thermal Expansion Coefficient: ~23–24 × 10⁻⁶ /K

- Specific Heat Capacity: ~900 J/kg·K

- Maximum Operating Temperature (Mechanical Properties): ~170 °C

6082 T6 Aluminum Properties – Electrical Properties

- Electrical conductivity: ~42% IACS (by volume)

- Electrical resistivity: ~0.38 × 10⁻⁶ Ω·m

6082 Aluminum Properties – Heat Treatment (T6)

The T6 temper is achieved by solution heat treatment followed by artificial aging. This process optimizes the precipitation of Mg₂Si particles, resulting in maximum strength.

6082 T6 Aluminum Properties – Manufacturing Characteristics

- Machinability: Good; tight chip curls can be produced using appropriate chip breakers.

- Cold formability: Good; cold working rating is "good."

- Weldability: Very suitable for gas-shielded welding, arc welding, and resistance welding processes; the non-precipitation zone may reduce the strength of the heat-affected zone. Best results can be achieved using aluminum-silicon filler. Recommended fillers: 4043 for autogenous welding, 5356 for connections with 7005 alloy.

- Brazability and weldability: Good

- Machinability: Good; in T6 temper condition, tight chip curls can be produced with chip breakers.

- Formability: Limited formability for thin-walled extrusions; surface roughness is coarser than that of 6063.

- Heat resistance: Softens above 170–200°C, not suitable for high-temperature applications.

6082 T6 Aluminum Properties – Corrosion Resistance

6082-T6 has excellent resistance to atmospheric and marine corrosion, making it suitable for marine and structural applications.

The corrosion resistance of 6082-T6 is better than that of 2-series (Al-Cu) and 7-series (Al-Zn-Mg) high-strength aluminum alloys, but weaker than pure aluminum and 3-series (Al-Mn) aluminum alloys:

Advantageous scenarios: Good corrosion resistance in air, freshwater, and neutral solutions; can be used directly (e.g., outdoor frames, rainwater pipes).

Disadvantageous scenarios: Prone to pitting or intergranular corrosion in seawater, acidic, or alkaline solutions; surface treatments are required to improve corrosion resistance.

Common methods include:

- Anodizing (forms an oxide film, improves wear resistance + corrosion resistance, can also be colored);

- Coating (such as powder coating, electrophoretic coating, suitable for aesthetic parts);

- Passivation treatment (short-term rust prevention, suitable for storage or transportation stages).

6082 T6 Aluminum Machinability: Suitable for Various Manufacturing Scenarios

Hot working performance:

Can easily undergo extrusion, forging, and rolling: good plasticity at high temperatures, can be extruded into complex cross-sections (e.g., profiles, tubes, special-shaped parts), commonly used in mass production of aluminum alloy frames and brackets.

Post-hot working, T6 heat treatment is required to restore high strength and prevent performance degradation.

Cold working performance:

Can be bent, stamped, and sheared, but cold working will cause work hardening (e.g., multiple bends can lead to brittleness), requiring "intermediate annealing (O temper)" to restore plasticity before further processing.

Machinability is better than 6061 (due to manganese refining grains), allowing efficient milling and drilling, but specialized aluminum alloy cutting tools should be used (to avoid material sticking to the tool).

Welding performance:

Can be welded using MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding; however, the weld area will have its age-hardening effect destroyed after welding, reducing strength by approximately 30% (partial strength can be restored through "post-weld artificial aging").

Note: Due to the high magnesium content, hot cracking may occur during welding. Welding current and speed need to be controlled, and matching filler wire should be used (e.g., ER5356).

6082 T6 Aluminum Properties – Common Applications

- Structural components: Scaffolding, trusses, bridges, railway car components

- Transportation and marine: Ship superstructures, marine extrusions (DNV certified)

- Machined parts: High-strength shafts, bars, rods for machinery

- Automotive and aerospace: High-stress parts, frames, connectors requiring medium-to-high strength and corrosion resistance

- Construction: Bridges, cranes, roof trusses

- Industrial: Beer barrels, milk stirrers, ore buckets

Comparison between 6082 T6 and 6061-T6

| Property | 6082-T6 | 6061-T6 | Description |

| Strength | Higher | High | The yield and tensile strength of 6082 are usually about 10-15% higher than 6061. |

| Hardness | Higher | High | Similarly, the Brinell/Weiss hardness of 6082 is slightly higher than 6061. |

| Corrosion resistance | Excellent | Excellent | Both are very good, with little difference. |

| Machinability | Excellent | Excellent | Both are easy to machine, but 6082 is slightly harder, causing slightly faster tool wear. |

Conclusion: If you need a 6-series aluminum alloy with higher strength than 6061-T6, 6082-T6 is an excellent choice.

6082 T6 Aluminum Limitations

- Weld zone defects: Post-weld heat treatment is required for critical applications.

- Extrusion process challenges: Not suitable for complex thin-walled designs.

- Temperature sensitivity: Avoid prolonged use above 200°C.

6082 T6 Aluminum Frequently Asked Questions

What are the properties of Aluminium 6082?

Aluminium 6082 is a medium-strength alloy from the Al-Mg-Si series with excellent corrosion resistance, good weldability, and machinability. It offers slightly higher strength and hardness compared to 6061, though with somewhat lower ductility. It is heat-treatable, commonly supplied in tempers such as T6 and T651.

What is the difference between 6061 T6 and 6082 T6 aluminum?

The main difference lies in composition and performance: 6082 T6 contains more manganese, giving it higher strength and hardness than 6061 T6, while 6061 T6 has slightly better ductility and formability. Both have excellent corrosion resistance and weldability, but 6082 is often preferred when higher strength is required.

What is 6082 T6 used for?

6082 T6 is widely used in structural applications such as bridges, cranes, trusses, transportation components, marine structures, and architectural frameworks. It is also applied in aerospace interiors, automotive parts, and general engineering where a strong yet lightweight material is needed.

What is equivalent to Aluminium 6082 T6?

Aluminium 6082 T6 is considered equivalent to AA6082 in the ASTM system, EN AW-6082 in the European standard (EN 573-3), and has comparable properties to AlSi1MgMn. In some applications, it can be an alternative to 6061 T6, though 6082 offers slightly higher strength.

6082-T6 aluminum alloy combines the high strength, good machinability, and corrosion resistance of heat-treatable alloys in the 6000 series, making it a versatile choice for engineering structures and high-load components.