6082 Aluminum Sheet

6082 aluminum sheet is an Al-Mg-Si series heat-treatable aluminum alloy plate, featuring medium strength, good weldability, and corrosion resistance. Compared with 6061, 6082 contains a higher silicon content and no copper element, which gives it higher weld seam strength and better resistance to intergranular corrosion during welding.

6082 aluminum sheet is an extremely well-balanced "all-purpose" aluminum alloy material, perfectly combining strength, corrosion resistance, machinability, and weldability. When you need a sheet that has higher strength than 6061 while also offering excellent overall performance, 6082-T6/T651 is a very reliable and popular choice. When ordering, be sure to specify the temper (such as T6 or T651), thickness, and dimensions you require.

6082 Aluminum Sheet is classified as "sheet" rather than "plate" by its thickness. Unlike thicker plates, sheets are usually produced by rolling or cold pressing into metric or imperial thicknesses, with a maximum thickness of up to 6 mm (0.25 inches). Sheets share the same alloy chemical composition and heat-treatable temper options as 6082 plates but are optimized for applications requiring weight reduction, finer thickness control, and enhanced formability.

6082 is a wrought aluminum-magnesium-silicon alloy in the 6000 series that cannot be cast and is usually formed through rolling, extrusion, and stamping. 6082 aluminum sheet is simply the thin rolled form of 6082 alloy (the distinction from plate lies in its thickness of about 6 mm), offering high strength, corrosion resistance, and excellent machinability, suitable for lightweight structural and decorative applications.

6082 Aluminum Sheet vs Plate Distinction

Thickness Standards

- 6082 Aluminum Sheet: Thickness ranges from 0.2 mm to 6.0 mm (0.008–0.25 inches).

- 6082 Aluminum Plate: In most regions, thickness exceeds 6 mm (0.25 inches) (≥6.35 mm or 0.25 inches in North America).

- Sheets thinner than 0.2 mm are classified as foil, while some standards classify sheets thicker than 200 mm as "extra-thick" plate.

6082 Aluminum Sheet Sizes and Forms

| Category | Specification Options | Description |

| Sheet | Thickness Range | ~0.2–6 mm |

| Common Widths | Typically 1000–2600 mm | |

| Common Lengths | Typically 6000–10000 mm | |

| Common Standard Sheet Sizes | 2000×1000 mm (thickness 0.6–3.0 mm) | |

| 2500×1250 mm (thickness 0.5–3.0 mm) | ||

| 3000×1250 mm (thickness 1.0–3.0 mm) | ||

| Plate | Thickness Range | ~6–250/300 mm |

| Common Widths | Typically 1000–2600 mm | |

| Common Lengths | Typically 6000–10000 mm | |

| Common Standard Plate Sizes | 2500×1250 mm (thickness up to 305 mm) | |

| 4000×2000 mm (thickness over 150 mm) |

6082 Aluminum Sheet: Surface Treatment Options

Mill Finish 6082 Aluminum Sheet

This is the standard form directly after rolling without additional finishing. It has a natural, slightly dull surface, suitable for applications where appearance is not critical or where further processing (painting, anodizing, polishing) will be done.

Polished 6082 Aluminum Sheet

Mechanically polished to create a smooth and shiny surface, improving aesthetics and reducing surface roughness. Often used for decorative purposes, signage, and applications where a bright, reflective look is required.

Brushed 6082 Aluminum Sheet

The surface is finished with a fine brushing process that leaves parallel grain lines, giving it a satin, matte appearance. Commonly used in architectural panels, interior decoration, and consumer electronics.

Anodized 6082 Aluminum Sheet

Undergoes an electrochemical anodizing process that thickens the natural oxide layer, enhancing corrosion resistance, wear resistance, and surface hardness. It can also be dyed in different colors for decorative applications.

Mirror Polished 6082 Aluminum Sheet

Polished to a near-mirror finish with extremely high reflectivity. Ideal for decorative applications, lighting reflectors, signage, and automotive trims where a glass-like appearance is desired.

Embossed 6082 Aluminum Sheet

Features textured or patterned surfaces (such as stucco, diamond, or other designs) to improve aesthetics and slip resistance. Widely used in flooring, decorative panels, and packaging.

Teflon Coated 6082 Aluminum Sheet

Coated with a layer of Teflon (PTFE), providing excellent non-stick, chemical resistance, and heat resistance. Commonly used in cookware, industrial equipment, and applications requiring easy-clean surfaces.

PE Coated 6082 Aluminum Sheet

Coated with a layer of polyethylene (PE) paint. Offers good weather resistance, durability, and color options, making it suitable for indoor applications, advertising panels, and decorative facades.

PVDF Coated 6082 Aluminum Sheet

Coated with polyvinylidene fluoride (PVDF) resin paint, known for outstanding UV resistance, weather resistance, and color retention. Extensively used in exterior cladding, roofing, and curtain wall systems for long-term durability.

6082 Aluminum Sheet Properties

- Medium to high strength: After heat treatment (usually in T6 temper), it achieves very high strength, superior to the 6061 alloy.

- Excellent corrosion resistance: Possesses good resistance to atmospheric corrosion and seawater corrosion, belonging to the category of anti-rust aluminum.

- Outstanding weldability: Can be welded by various methods (such as TIG and MIG welding), with stable performance after welding, and strength can be restored through heat treatment after welding.

- Anodizable: Good surface treatment properties, capable of forming an attractive and durable protective layer after anodizing.

- Good machinability: Excellent machinability and bendability, suitable for stamping and deep drawing; can be welded by MIG/TIG (the welded area may require filler alloys, such as 4043 or 5356).

6082 Aluminum Sheet Chemical Composition

The typical chemical composition of 6082 aluminum alloy (weight percentage) is as follows:

| Element | Content Range (%) |

| Silicon (Si) | 0.70–1.30 |

| Magnesium (Mg) | 0.60–1.20 |

| Manganese (Mn) | 0.40–1.00 |

| Iron (Fe) | ≤0.50 |

| Copper (Cu) | ≤0.10 |

| Zinc (Zn) | ≤0.20 |

| Chromium (Cr) | ≤0.25 |

| Titanium (Ti) | ≤0.10 |

| Other Impurities | ≤0.15 |

| Aluminum (Al) | Balance |

6082 Aluminum Sheet Mechanical Properties

At room temperature, the typical mechanical properties of 6082-T6 (solution treated + artificially aged) sheet include:

- Ultimate Tensile Strength (UTS): 310–340 MPa

- Yield Strength: Approximately 260–310 MPa

- Elongation: Around 8–12%

- Vickers Hardness: Approximately 90–110 HV

- Young’s Modulus: Approximately 71 GPa

6082 Aluminum Sheet Common Tempers

Common tempers for 6082 aluminum alloy include:

- O Temper (Annealed): Offers maximum ductility and toughness;

- T4 Temper (Solution Heat Treated): Solution treated and naturally aged, suitable for low-stress applications;

- T6 Temper (Solution Heat Treated + Artificially Aged): Provides maximum strength and is the most commonly used temper for sheets;

- T651 Temper: Same as T6 but stress-relieved by stretching, suitable for applications requiring tight dimensional tolerance.

6082 Aluminum Sheet Processing and Weldability

6082 alloy sheets can be produced by cold rolling, hot rolling, or extrusion processes, and exhibit good machinability, making them suitable for CNC machining.

This alloy has good weldability, though the strength in the weld zone may decrease. Aluminum-silicon filler wires (such as 4043) are commonly used for MIG welding; when welding with high-strength 7005 aluminum alloys, 5356 filler wire is recommended.

6082 Aluminum Sheet Corrosion Resistance

6082 alloy demonstrates excellent corrosion resistance in atmospheric and marine environments due to the protective passivation film formed by the Mg₂Si precipitates. In salt spray environments, its corrosion resistance surpasses that of 6061 alloy, making it suitable for ship decks, marine structures, and similar applications.

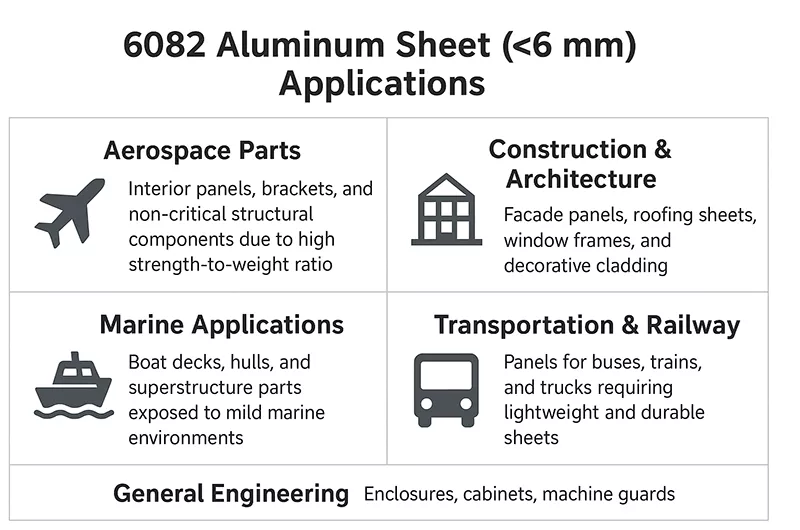

6082 Aluminum Sheet Applications

- Automotive parts: Panels, body components, and structural reinforcements that require lightweight and corrosion resistance.

- Aerospace components: Interior panels, brackets, and non-critical structural parts due to the high strength-to-weight ratio.

- Construction & architecture: Facade panels, roofing sheets, window frames, and decorative cladding.

- Marine applications: Ship decks, hulls, and superstructure parts exposed to mild marine environments.

- Transportation & railway: Panels for buses, trains, and trucks that require lightweight and durable sheets.

- General engineering: Enclosures, cabinets, machine guards, and heat sinks.

| Thickness (mm) | Common Applications | Key Advantages |

| 1–2 mm | Decorative panels, signage, thin automotive body panels, electronic casings | Lightweight, easy to bend/form, anodizable for aesthetic finish |

| 2–3 mm | Roofing sheets, facade cladding, boat superstructures, bicycle frames | Good corrosion resistance, moderate strength, easy to fabricate |

| 3–4 mm | Vehicle panels, railway interiors, ladders, machinery covers | Balanced strength and weight, suitable for welding/bolting |

| 4–5 mm | Structural panels in construction, transport containers, marine fittings | Higher strength while maintaining formability, corrosion resistant |

| 5–6 mm | Light structural components, machinery guards, brackets, aerospace interior parts | High strength-to-weight ratio, suitable for bending, machining, and anodizing |

6082 Aluminum Sheet Standards and Specifications

6082 sheets comply with international standards such as EN 573-3 (chemical composition), EN 485-2 (mechanical properties of sheets and strips), and ISO 6361 (wrought sheets and strips). Depending on the end-use requirements, specific regional specifications (ASTM, JIS) may also apply.

The 6082 alloy sheets mainly conform to the following international standards:

- EN 573-3: Chemical composition and product forms

- EN 485-2: Mechanical properties of sheets, strips, and plates

- ISO 6361: Standards for aluminum and aluminum alloy sheets, strips, and plates

6082 Aluminum Sheet Fabrication

- Machining: Exhibits good machinability in the T6 temper.

- Welding: Suitable for TIG/MIG welding; post-weld heat treatment can restore performance.

- Forming: Moderate formability; better in annealed (O) condition.

Top-Selling 6082 Aluminum Sheet Dimensions

| Item | Thickness (inches) | Temper | Width (inches) | Length (inches) |

| 0.04" 6082 T4 Aluminum Sheet 24"x96" | 0.04" | T4 | 24" | 96" |

| 0.04" 6082 T451 Aluminum Sheet 24"x96" | 0.04" | T451 | 24" | 96" |

| 0.04" 6082 T6 Aluminum Sheet 24"x96" | 0.04" | T6 | 24" | 96" |

| 0.04" 6082 T651 Aluminum Sheet 24"x96" | 0.04" | T651 | 24" | 96" |

| 0.04" 6082 T4 Aluminum Sheet 24"x120" | 0.04" | T4 | 24" | 120" |

| 0.04" 6082 T451 Aluminum Sheet 24"x120" | 0.04" | T451 | 24" | 120" |

| 0.04" 6082 T6 Aluminum Sheet 24"x120" | 0.04" | T6 | 24" | 120" |

| 0.04" 6082 T651 Aluminum Sheet 24"x120" | 0.04" | T651 | 24" | 120" |

| 0.04" 6082 T4 Aluminum Sheet 24"x144" | 0.04" | T4 | 24" | 144" |

| 0.04" 6082 T451 Aluminum Sheet 24"x144" | 0.04" | T451 | 24" | 144" |

| 0.04" 6082 T6 Aluminum Sheet 24"x144" | 0.04" | T6 | 24" | 144" |

| 0.04" 6082 T651 Aluminum Sheet 24"x144" | 0.04" | T651 | 24" | 144" |

| 0.04" 6082 T4 Aluminum Sheet 36"x96" | 0.04" | T4 | 36" | 96" |

| 0.04" 6082 T451 Aluminum Sheet 36"x96" | 0.04" | T451 | 36" | 96" |

| 0.04" 6082 T6 Aluminum Sheet 36"x96" | 0.04" | T6 | 36" | 96" |

| 0.04" 6082 T651 Aluminum Sheet 36"x96" | 0.04" | T651 | 36" | 96" |

| 0.04" 6082 T4 Aluminum Sheet 36"x120" | 0.04" | T4 | 36" | 120" |

| 0.04" 6082 T451 Aluminum Sheet 36"x120" | 0.04" | T451 | 36" | 120" |

| 0.04" 6082 T6 Aluminum Sheet 36"x120" | 0.04" | T6 | 36" | 120" |

| 0.04" 6082 T651 Aluminum Sheet 36"x120" | 0.04" | T651 | 36" | 120" |

| 0.04" 6082 T4 Aluminum Sheet 48"x96" | 0.04" | T4 | 48" | 96" |

| 0.04" 6082 T451 Aluminum Sheet 48"x96" | 0.04" | T451 | 48" | 96" |

| 0.04" 6082 T6 Aluminum Sheet 48"x96" | 0.04" | T6 | 48" | 96" |

| 0.04" 6082 T651 Aluminum Sheet 48"x96" | 0.04" | T651 | 48" | 96" |

| 0.04" 6082 T4 Aluminum Sheet 48"x120" | 0.04" | T4 | 48" | 120" |

| 0.04" 6082 T451 Aluminum Sheet 48"x120" | 0.04" | T451 | 48" | 120" |

| 0.04" 6082 T6 Aluminum Sheet 48"x120" | 0.04" | T6 | 48" | 120" |

| 0.04" 6082 T651 Aluminum Sheet 48"x120" | 0.04" | T651 | 48" | 120" |

| 0.04" 6082 T4 Aluminum Sheet 48"x144" | 0.04" | T4 | 48" | 144" |

| 0.04" 6082 T451 Aluminum Sheet 48"x144" | 0.04" | T451 | 48" | 144" |

| 0.04" 6082 T6 Aluminum Sheet 48"x144" | 0.04" | T6 | 48" | 144" |

| 0.04" 6082 T651 Aluminum Sheet 48"x144" | 0.04" | T651 | 48" | 144" |

| 0.04" 6082 T4 Aluminum Sheet 72"x144" | 0.04" | T4 | 72" | 144" |

| 0.04" 6082 T451 Aluminum Sheet 72"x144" | 0.04" | T451 | 72" | 144" |

| 0.04" 6082 T6 Aluminum Sheet 72"x144" | 0.04" | T6 | 72" | 144" |

| 0.04" 6082 T651 Aluminum Sheet 72"x144" | 0.04" | T651 | 72" | 144" |

| 0.125" 6082 T4 Aluminum Sheet 24"x96" | 0.125" | T4 | 24" | 96" |

| 0.125" 6082 T451 Aluminum Sheet 24"x96" | 0.125" | T451 | 24" | 96" |

| 0.125" 6082 T6 Aluminum Sheet 24"x96" | 0.125" | T6 | 24" | 96" |

| 0.125" 6082 T651 Aluminum Sheet 24"x96" | 0.125" | T651 | 24" | 96" |

| 0.125" 6082 T4 Aluminum Sheet 24"x120" | 0.125" | T4 | 24" | 120" |

| 0.125" 6082 T451 Aluminum Sheet 24"x120" | 0.125" | T451 | 24" | 120" |

| 0.125" 6082 T6 Aluminum Sheet 24"x120" | 0.125" | T6 | 24" | 120" |

| 0.125" 6082 T651 Aluminum Sheet 24"x120" | 0.125" | T651 | 24" | 120" |

| 0.125" 6082 T4 Aluminum Sheet 24"x144" | 0.125" | T4 | 24" | 144" |

| 0.125" 6082 T451 Aluminum Sheet 24"x144" | 0.125" | T451 | 24" | 144" |

| 0.125" 6082 T6 Aluminum Sheet 24"x144" | 0.125" | T6 | 24" | 144" |

| 0.125" 6082 T651 Aluminum Sheet 24"x144" | 0.125" | T651 | 24" | 144" |

| 0.125" 6082 T4 Aluminum Sheet 36"x96" | 0.125" | T4 | 36" | 96" |

| 0.125" 6082 T451 Aluminum Sheet 36"x96" | 0.125" | T451 | 36" | 96" |

| 0.125" 6082 T6 Aluminum Sheet 36"x96" | 0.125" | T6 | 36" | 96" |

| 0.125" 6082 T651 Aluminum Sheet 36"x96" | 0.125" | T651 | 36" | 96" |

| 0.125" 6082 T4 Aluminum Sheet 36"x120" | 0.125" | T4 | 36" | 120" |

| 0.125" 6082 T451 Aluminum Sheet 36"x120" | 0.125" | T451 | 36" | 120" |

| 0.125" 6082 T6 Aluminum Sheet 36"x120" | 0.125" | T6 | 36" | 120" |

| 0.125" 6082 T651 Aluminum Sheet 36"x120" | 0.125" | T651 | 36" | 120" |

| 0.125" 6082 T4 Aluminum Sheet 48"x96" | 0.125" | T4 | 48" | 96" |

| 0.125" 6082 T451 Aluminum Sheet 48"x96" | 0.125" | T451 | 48" | 96" |

| 0.125" 6082 T6 Aluminum Sheet 48"x96" | 0.125" | T6 | 48" | 96" |

| 0.125" 6082 T651 Aluminum Sheet 48"x96" | 0.125" | T651 | 48" | 96" |

| 0.125" 6082 T4 Aluminum Sheet 48"x120" | 0.125" | T4 | 48" | 120" |

| 0.125" 6082 T451 Aluminum Sheet 48"x120" | 0.125" | T451 | 48" | 120" |

| 0.125" 6082 T6 Aluminum Sheet 48"x120" | 0.125" | T6 | 48" | 120" |

| 0.125" 6082 T651 Aluminum Sheet 48"x120" | 0.125" | T651 | 48" | 120" |

| 0.125" 6082 T4 Aluminum Sheet 48"x144" | 0.125" | T4 | 48" | 144" |

| 0.125" 6082 T451 Aluminum Sheet 48"x144" | 0.125" | T451 | 48" | 144" |

| 0.125" 6082 T6 Aluminum Sheet 48"x144" | 0.125" | T6 | 48" | 144" |

| 0.125" 6082 T651 Aluminum Sheet 48"x144" | 0.125" | T651 | 48" | 144" |

| 0.125" 6082 T4 Aluminum Sheet 72"x144" | 0.125" | T4 | 72" | 144" |

| 0.125" 6082 T451 Aluminum Sheet 72"x144" | 0.125" | T451 | 72" | 144" |

| 0.125" 6082 T6 Aluminum Sheet 72"x144" | 0.125" | T6 | 72" | 144" |

| 0.125" 6082 T651 Aluminum Sheet 72"x144" | 0.125" | T651 | 72" | 144" |

| 0.16" 6082 T4 Aluminum Sheet 24"x96" | 0.16" | T4 | 24" | 96" |

| 0.16" 6082 T451 Aluminum Sheet 24"x96" | 0.16" | T451 | 24" | 96" |

| 0.16" 6082 T6 Aluminum Sheet 24"x96" | 0.16" | T6 | 24" | 96" |

| 0.16" 6082 T651 Aluminum Sheet 24"x96" | 0.16" | T651 | 24" | 96" |

| 0.16" 6082 T4 Aluminum Sheet 24"x120" | 0.16" | T4 | 24" | 120" |

| 0.16" 6082 T451 Aluminum Sheet 24"x120" | 0.16" | T451 | 24" | 120" |

| 0.16" 6082 T6 Aluminum Sheet 24"x120" | 0.16" | T6 | 24" | 120" |

| 0.16" 6082 T651 Aluminum Sheet 24"x120" | 0.16" | T651 | 24" | 120" |

| 0.16" 6082 T4 Aluminum Sheet 24"x144" | 0.16" | T4 | 24" | 144" |

| 0.16" 6082 T451 Aluminum Sheet 24"x144" | 0.16" | T451 | 24" | 144" |

| 0.16" 6082 T6 Aluminum Sheet 24"x144" | 0.16" | T6 | 24" | 144" |

| 0.16" 6082 T651 Aluminum Sheet 24"x144" | 0.16" | T651 | 24" | 144" |

| 0.16" 6082 T4 Aluminum Sheet 36"x96" | 0.16" | T4 | 36" | 96" |

| 0.16" 6082 T451 Aluminum Sheet 36"x96" | 0.16" | T451 | 36" | 96" |

| 0.16" 6082 T6 Aluminum Sheet 36"x96" | 0.16" | T6 | 36" | 96" |

| 0.16" 6082 T651 Aluminum Sheet 36"x96" | 0.16" | T651 | 36" | 96" |

| 0.16" 6082 T4 Aluminum Sheet 36"x120" | 0.16" | T4 | 36" | 120" |

| 0.16" 6082 T451 Aluminum Sheet 36"x120" | 0.16" | T451 | 36" | 120" |

| 0.16" 6082 T6 Aluminum Sheet 36"x120" | 0.16" | T6 | 36" | 120" |

| 0.16" 6082 T651 Aluminum Sheet 36"x120" | 0.16" | T651 | 36" | 120" |

| 0.16" 6082 T4 Aluminum Sheet 48"x96" | 0.16" | T4 | 48" | 96" |

| 0.16" 6082 T451 Aluminum Sheet 48"x96" | 0.16" | T451 | 48" | 96" |

| 0.16" 6082 T6 Aluminum Sheet 48"x96" | 0.16" | T6 | 48" | 96" |

| 0.16" 6082 T651 Aluminum Sheet 48"x96" | 0.16" | T651 | 48" | 96" |

| 0.16" 6082 T4 Aluminum Sheet 48"x120" | 0.16" | T4 | 48" | 120" |

| 0.16" 6082 T451 Aluminum Sheet 48"x120" | 0.16" | T451 | 48" | 120" |

| 0.16" 6082 T6 Aluminum Sheet 48"x120" | 0.16" | T6 | 48" | 120" |

| 0.16" 6082 T651 Aluminum Sheet 48"x120" | 0.16" | T651 | 48" | 120" |

| 0.16" 6082 T4 Aluminum Sheet 48"x144" | 0.16" | T4 | 48" | 144" |

| 0.16" 6082 T451 Aluminum Sheet 48"x144" | 0.16" | T451 | 48" | 144" |

| 0.16" 6082 T6 Aluminum Sheet 48"x144" | 0.16" | T6 | 48" | 144" |

| 0.16" 6082 T651 Aluminum Sheet 48"x144" | 0.16" | T651 | 48" | 144" |

| 0.16" 6082 T4 Aluminum Sheet 72"x144" | 0.16" | T4 | 72" | 144" |

| 0.16" 6082 T451 Aluminum Sheet 72"x144" | 0.16" | T451 | 72" | 144" |

| 0.16" 6082 T6 Aluminum Sheet 72"x144" | 0.16" | T6 | 72" | 144" |

| 0.16" 6082 T651 Aluminum Sheet 72"x144" | 0.16" | T651 | 72" | 144" |

| 0.20" 6082 T4 Aluminum Sheet 24"x96" | 0.20" | T4 | 24" | 96" |

| 0.20" 6082 T451 Aluminum Sheet 24"x96" | 0.20" | T451 | 24" | 96" |

| 0.20" 6082 T6 Aluminum Sheet 24"x96" | 0.20" | T6 | 24" | 96" |

| 0.20" 6082 T651 Aluminum Sheet 24"x96" | 0.20" | T651 | 24" | 96" |

| 0.20" 6082 T4 Aluminum Sheet 24"x120" | 0.20" | T4 | 24" | 120" |

| 0.20" 6082 T451 Aluminum Sheet 24"x120" | 0.20" | T451 | 24" | 120" |

| 0.20" 6082 T6 Aluminum Sheet 24"x120" | 0.20" | T6 | 24" | 120" |

| 0.20" 6082 T651 Aluminum Sheet 24"x120" | 0.20" | T651 | 24" | 120" |

| 0.20" 6082 T4 Aluminum Sheet 24"x144" | 0.20" | T4 | 24" | 144" |

| 0.20" 6082 T451 Aluminum Sheet 24"x144" | 0.20" | T451 | 24" | 144" |

| 0.20" 6082 T6 Aluminum Sheet 24"x144" | 0.20" | T6 | 24" | 144" |

| 0.20" 6082 T651 Aluminum Sheet 24"x144" | 0.20" | T651 | 24" | 144" |

| 0.20" 6082 T4 Aluminum Sheet 36"x96" | 0.20" | T4 | 36" | 96" |

| 0.20" 6082 T451 Aluminum Sheet 36"x96" | 0.20" | T451 | 36" | 96" |

| 0.20" 6082 T6 Aluminum Sheet 36"x96" | 0.20" | T6 | 36" | 96" |

| 0.20" 6082 T651 Aluminum Sheet 36"x96" | 0.20" | T651 | 36" | 96" |

| 0.20" 6082 T4 Aluminum Sheet 36"x120" | 0.20" | T4 | 36" | 120" |

| 0.20" 6082 T451 Aluminum Sheet 36"x120" | 0.20" | T451 | 36" | 120" |

| 0.20" 6082 T6 Aluminum Sheet 36"x120" | 0.20" | T6 | 36" | 120" |

| 0.20" 6082 T651 Aluminum Sheet 36"x120" | 0.20" | T651 | 36" | 120" |

| 0.20" 6082 T4 Aluminum Sheet 48"x96" | 0.20" | T4 | 48" | 96" |

| 0.20" 6082 T451 Aluminum Sheet 48"x96" | 0.20" | T451 | 48" | 96" |

| 0.20" 6082 T6 Aluminum Sheet 48"x96" | 0.20" | T6 | 48" | 96" |

| 0.20" 6082 T651 Aluminum Sheet 48"x96" | 0.20" | T651 | 48" | 96" |

| 0.20" 6082 T4 Aluminum Sheet 48"x120" | 0.20" | T4 | 48" | 120" |

| 0.20" 6082 T451 Aluminum Sheet 48"x120" | 0.20" | T451 | 48" | 120" |

| 0.20" 6082 T6 Aluminum Sheet 48"x120" | 0.20" | T6 | 48" | 120" |

| 0.20" 6082 T651 Aluminum Sheet 48"x120" | 0.20" | T651 | 48" | 120" |

| 0.20" 6082 T4 Aluminum Sheet 48"x144" | 0.20" | T4 | 48" | 144" |

| 0.20" 6082 T451 Aluminum Sheet 48"x144" | 0.20" | T451 | 48" | 144" |

| 0.20" 6082 T6 Aluminum Sheet 48"x144" | 0.20" | T6 | 48" | 144" |

| 0.20" 6082 T651 Aluminum Sheet 48"x144" | 0.20" | T651 | 48" | 144" |

| 0.20" 6082 T4 Aluminum Sheet 72"x144" | 0.20" | T4 | 72" | 144" |

| 0.20" 6082 T451 Aluminum Sheet 72"x144" | 0.20" | T451 | 72" | 144" |

| 0.20" 6082 T6 Aluminum Sheet 72"x144" | 0.20" | T6 | 72" | 144" |

| 0.20" 6082 T651 Aluminum Sheet 72"x144" | 0.20" | T651 | 72" | 144" |

| 0.25" 6082 T4 Aluminum Sheet 24"x96" | 0.25" | T4 | 24" | 96" |

| 0.25" 6082 T451 Aluminum Sheet 24"x96" | 0.25" | T451 | 24" | 96" |

| 0.25" 6082 T6 Aluminum Sheet 24"x96" | 0.25" | T6 | 24" | 96" |

| 0.25" 6082 T651 Aluminum Sheet 24"x96" | 0.25" | T651 | 24" | 96" |

| 0.25" 6082 T4 Aluminum Sheet 24"x120" | 0.25" | T4 | 24" | 120" |

| 0.25" 6082 T451 Aluminum Sheet 24"x120" | 0.25" | T451 | 24" | 120" |

| 0.25" 6082 T6 Aluminum Sheet 24"x120" | 0.25" | T6 | 24" | 120" |

| 0.25" 6082 T651 Aluminum Sheet 24"x120" | 0.25" | T651 | 24" | 120" |

| 0.25" 6082 T4 Aluminum Sheet 24"x144" | 0.25" | T4 | 24" | 144" |

| 0.25" 6082 T451 Aluminum Sheet 24"x144" | 0.25" | T451 | 24" | 144" |

| 0.25" 6082 T6 Aluminum Sheet 24"x144" | 0.25" | T6 | 24" | 144" |

| 0.25" 6082 T651 Aluminum Sheet 24"x144" | 0.25" | T651 | 24" | 144" |

| 0.25" 6082 T4 Aluminum Sheet 36"x96" | 0.25" | T4 | 36" | 96" |

| 0.25" 6082 T451 Aluminum Sheet 36"x96" | 0.25" | T451 | 36" | 96" |

| 0.25" 6082 T6 Aluminum Sheet 36"x96" | 0.25" | T6 | 36" | 96" |

| 0.25" 6082 T651 Aluminum Sheet 36"x96" | 0.25" | T651 | 36" | 96" |

| 0.25" 6082 T4 Aluminum Sheet 36"x120" | 0.25" | T4 | 36" | 120" |

| 0.25" 6082 T451 Aluminum Sheet 36"x120" | 0.25" | T451 | 36" | 120" |

| 0.25" 6082 T6 Aluminum Sheet 36"x120" | 0.25" | T6 | 36" | 120" |

| 0.25" 6082 T651 Aluminum Sheet 36"x120" | 0.25" | T651 | 36" | 120" |

| 0.25" 6082 T4 Aluminum Sheet 48"x96" | 0.25" | T4 | 48" | 96" |

| 0.25" 6082 T451 Aluminum Sheet 48"x96" | 0.25" | T451 | 48" | 96" |

| 0.25" 6082 T6 Aluminum Sheet 48"x96" | 0.25" | T6 | 48" | 96" |

| 0.25" 6082 T651 Aluminum Sheet 48"x96" | 0.25" | T651 | 48" | 96" |

| 0.25" 6082 T4 Aluminum Sheet 48"x120" | 0.25" | T4 | 48" | 120" |

| 0.25" 6082 T451 Aluminum Sheet 48"x120" | 0.25" | T451 | 48" | 120" |

| 0.25" 6082 T6 Aluminum Sheet 48"x120" | 0.25" | T6 | 48" | 120" |

| 0.25" 6082 T651 Aluminum Sheet 48"x120" | 0.25" | T651 | 48" | 120" |

| 0.25" 6082 T4 Aluminum Sheet 48"x144" | 0.25" | T4 | 48" | 144" |

| 0.25" 6082 T451 Aluminum Sheet 48"x144" | 0.25" | T451 | 48" | 144" |

| 0.25" 6082 T6 Aluminum Sheet 48"x144" | 0.25" | T6 | 48" | 144" |

| 0.25" 6082 T651 Aluminum Sheet 48"x144" | 0.25" | T651 | 48" | 144" |

| 0.25" 6082 T4 Aluminum Sheet 72"x144" | 0.25" | T4 | 72" | 144" |

| 0.25" 6082 T451 Aluminum Sheet 72"x144" | 0.25" | T451 | 72" | 144" |

| 0.25" 6082 T6 Aluminum Sheet 72"x144" | 0.25" | T6 | 72" | 144" |

| 0.25" 6082 T651 Aluminum Sheet 72"x144" | 0.25" | T651 | 72" | 144" |

Advantages of 6082 Aluminum Sheet Over Similar Alloys

- Higher strength than 6061 aluminum, making it ideal for heavy-duty applications.

- Better corrosion resistance than many steel alternatives.

- Widely used in Europe (similar to 6061 aluminum in North America).

Comparison Between 6082 and 6061 Aluminum Alloys

| Properties | 6082 | 6061 |

| Strength | Slightly higher | Slightly lower |

| Hardness | Slightly higher | Slightly lower |

| Ductility | Slightly lower | Slightly better |

| Machinability | Excellent | Excellent |

| Weldability | Excellent | Excellent |

| Corrosion resistance | Excellent | Excellent |

| Main difference | Higher manganese (Mn) content, which is the main reason for its higher strength. | Lower manganese content, contains a small amount of copper (Cu). |

| Processing cost | Mature hot-rolling process, cost close to 6061 | Cold working is more economical, suitable for complex forming |

How to choose: If the design requires extremely high strength, 6082-T6 is preferred; if higher forming and bending performance is required, 6061-O or T4 may be more suitable. In many cases, the two can be used interchangeably.

Comparison with 6061 and 5052

6082, 6061, and 5052 are all popular aluminum alloys, but they differ in key properties:

| Property | 6082 (T6/T651) | 6061 (T6) | 5052 (H32) |

| Tensile Strength (UTS) | ≈295–300 MPa | ≈290 MPa | ≈228 MPa |

| Yield Strength (0.2%) | ≈240–255 MPa | ≈240 MPa | ≈193 MP |

| Corrosion Resistance | Excellent (very good in marine) | Very good (commonly used in marine) | Superior (5xxx-series, marine-grade) |

| Machinability | Good (comparable to 6061) | Good (very easy to machine) | Fair (only moderate machinability) |

| Formability | Good (in annealed O or T4); moderate in T6 | Good in annealed O; limited in T6 | Excellent (easily formed, especially in H32/O tempers) |

6082 Aluminum Sheet Production Methods

6082 sheets are produced from hot-rolled or cold-rolled alloy slabs, followed by optional cold rolling to control thickness. Compared to hot-rolled sheet production, cold rolling improves surface quality and dimensional accuracy.

6082 Aluminum Sheet Frequently Asked Questions

Which aluminum is stronger, 6061 or 6082?

6082 aluminum is generally stronger than 6061. While both are medium-strength alloys, 6082 has a higher tensile and yield strength, making it more suitable for structural applications where strength is important.

What is 6082 grade aluminium?

6082 is an aluminum-magnesium-silicon (Al-Mg-Si) alloy known for its high strength, excellent corrosion resistance, and good weldability. It is commonly used in construction, transportation, marine, and aerospace applications.

Is 6082 aluminium bendable?

Yes, 6082 aluminum is bendable, especially in softer tempers like T4 or O (annealed). However, in harder tempers like T6 or T651, it is less ductile and requires careful handling or pre-heating to prevent cracking during bending.

What is the difference between 7075 and aluminum 6082?

7075 is a high-strength aluminum-zinc alloy, much stronger than 6082, but it is less corrosion-resistant and more expensive. 6082 offers a better balance of strength, corrosion resistance, and workability, while 7075 is mainly used in aerospace and applications where maximum strength is critical.

Why Choose 6082 Aluminum Sheet?

- Versatility: Balances strength, weldability, and corrosion resistance.

- Cost-effectiveness: Durable with minimal maintenance needs.

- Sustainability: Fully recyclable with minimal environmental impact.