2024 T351 Aluminum Plate

2024-T351 aluminum plate is a high-strength, highly durable aluminum alloy sheet widely used in aerospace, transportation, and other structural components where high strength and resistance to metal fatigue are critical. It is a specific temper of 2024 aluminum, which undergoes a series of precise heat treatment and stress-relief processes, providing excellent mechanical properties and durability.

2024-T351 aluminum alloy is a typical high-strength alloy in the Al-Cu-Mg system and is one of the most widely used alloys among high-strength aluminum. This alloy has excellent overall performance, especially in strength, toughness, and fatigue properties, and is widely used in aerospace and other high-performance demanding fields.

2024-T351 belongs to the 2000 series alloys. The T351 designation indicates that the material has undergone solution heat treatment, stress relief by stretching, and then natural aging.

What is 2024 T351 aluminum?

2024 T351 aluminum is a high-strength alloy that has undergone solution heat treatment, stress relief, and natural aging. It is suitable for applications requiring high strength and fatigue resistance, such as aircraft structures, military vehicles, and other high-performance applications.

- Solution Heat Treatment: The 2024 aluminum alloy is heated to a specific temperature to ensure that the alloying elements dissolve uniformly, placing it in a high-temperature state.

- Stress Relief: The 2024 aluminum plate is stretched to a certain extent to relieve internal stresses. The amount of stretching varies depending on the product form (such as thin sheets, plates, bars, or forgings). Stress relief helps improve the uniformity and stability of the alloy, reducing deformation during later processing.

- Natural Aging: After solution heat treatment, the 2024 aluminum alloy naturally ages at room temperature, further enhancing its strength and hardness.

2024 T351 Chemical Composition

| Element | Cu | Mg | Si | Fe | Mn | Zn | Cr | Ti | Al |

| Content (%) | 3.8-4.9 | 1.2-1.8 | ≤0.50 | ≤0.50 | 0.3-0.9 | ≤0.25 | ≤0.10 | ≤0.15 | Balance |

2024 T351 Physical Properties

- Density: 2.78 g/cm³, approximately 65% lighter than steel, offering excellent lightweight advantage

- Melting Point: approximately 640°C

- Coefficient of Thermal Expansion: 23.1×10⁻⁶/K (20-100°C)

- Elastic Modulus: 73 GPa (approx. 10.6 Msi)

- Low-Temperature Toughness: Maintains high strength and toughness even in low-temperature environments, making it especially suitable for extreme temperature applications

2024 T351 Aluminum Informations

| Property | Description |

| Alloy | 2024 |

| Temper | T351 (Solution Heat Treatment + Stress Relief + Natural Aging) |

| Solution Heat Treatment | The 2024 aluminum alloy is heated to a specific temperature to ensure that the alloying elements dissolve uniformly. |

| Stress Relief | The aluminum alloy plate is stretched to a certain extent to relieve internal stresses. The amount of stretching depends on the product form (such as thin sheets, plates, bars, or forgings). |

| Natural Aging | After solution heat treatment, the aluminum alloy naturally ages at room temperature, increasing its strength and hardness. |

| Metal Fatigue Resistance | Extremely strong resistance to metal fatigue, capable of withstanding long-term repetitive loads and high-stress environments without fracturing. |

| Corrosion Resistance | Fair, typically requiring additional coatings to enhance corrosion resistance. |

| Main Applications | Aerospace (aircraft fuselage, wing structures, etc.), automotive (high-performance cars, racing engine components, etc.), military (high-strength structural parts), etc. |

| Machinability | Good machinability, but due to its high strength, more advanced equipment may be needed for machining. |

| Weldability | Special attention is needed during welding to control the heat-affected zone and avoid stress concentration. |

| Main Advantages | High strength, excellent metal fatigue resistance, suitable for structural components subjected to high stress and repeated loads. |

2024-T351 Aluminum Properties

2024 T351 aluminum combines high strength with excellent fatigue resistance, making it an ideal choice for structural components in high-stress applications, especially in aerospace. While it has moderate corrosion resistance, proper corrosion protection can be applied.

| Property | Description |

| Strength | 2024-T351 aluminum alloy has high strength due to its higher copper content, especially when compared to other aluminum alloys. |

| Fatigue Resistance | The alloy exhibits excellent fatigue resistance, making it suitable for structural components subjected to repetitive loads, such as aircraft structures. |

| Lightweight | With a density of 2.78 g/cm³, it is relatively light, making it ideal for applications where weight is a critical factor, particularly in aerospace. |

| Corrosion Resistance | Although 2024-T351 is strong, it is more susceptible to corrosion than other aluminum alloys. It is often used with a protective coating or cladding (a layer of pure aluminum). |

| Machinability | It has good machinability, but due to its higher strength, it may be more difficult to machine than other lower-strength alloys. |

| Application Suitability | Mainly used in aerospace (aircraft fuselage, wings), military, and automotive industries, especially in applications requiring high strength, fatigue resistance, and low weight. |

2024 T351 Product Forms and Specifications

Main Product Forms of 2024 T351

2024 T351 Plate/Sheet

- Thin Plate/Sheet: typically 0.125" to 0.5" thick

- Medium Plate: 0.5" to 1.5" thick

- Thick Plate: thicker than 1.5"

2024 T351 Rod/Bar

- Round Bar: diameters from 1/8" to 6"

- Square Bar: side lengths from 1/2" to 4"

- Hexagon Bar: distance across flats from 1/2" to 4"

2024 T351 Tube/Pipe

- Seamless Tube

- Welded Tube

- Precision Tube

Special Shapes

- Ordinary Wire

- Rivet Wire

- Extruded Profiles: custom cross-sectional shapes

- Forgings

Typical Specifications of 2024 T351

2024 T351 Plate/Sheet Specifications

- Thickness: 0.032" to 4.0"

- Width: typically 48" or 60"

- Length: typically 96", 120", or 144"

- Tolerances: in accordance with AMS-QQ-A-250/5 or AMS-QQ-A-250/4 standards

2024 T351 Rod/Bar Specifications

- Diameter: 0.125" to 6.0"

- Straightness: no more than 0.010" per foot

- Surface Finish: cold-finished surface roughness typically 125-200 μin

2024 T351 Tube/Pipe Specifications

- Outer Diameter: 0.250" to 6.0"

- Wall Thickness: 0.020" to 0.500"

- Length: typically 12' or 20'

2024 T351 Supply Tempers

- T351: Solution heat-treated, stress-relieved by stretching, and naturally aged; suitable for thick plates

- T3510: Solution heat-treated, stress-relieved by stretching, and naturally aged; suitable for rolled or cold-finished bars

- T3511: Solution heat-treated, stress-relieved by stretching, and naturally aged; suitable for die forgings, forged rings, or rolled rings

2024 T351 Surface Treatments

- Bare Aluminum Surface: Retains the original state of 2024 aluminum alloy without any additional treatment; suitable for applications where corrosion resistance is not critical but high strength needs to be fully utilized.

- Anodizing: Forms an oxide layer on the surface through electrochemical processing, enhancing corrosion and wear resistance of 2024 T351. However, due to the high copper content (approximately 4.4%), the oxide film is porous and prone to "burning" defects caused by electrolytic heating, usually appearing in a darker color.

- Painting or Coating: Covers the surface with organic coatings (e.g., powder coating, electrophoretic paint) to provide additional corrosion protection and decorative effects, especially suitable for high-humidity or outdoor environments.

- Alclad Treatment: Covers the 2024 T351 substrate with a layer of pure aluminum (e.g., 1050, 1100) or 3003 aluminum alloy (approximately 1.5% thick), significantly enhancing corrosion resistance through electrochemical protection; widely used in aerospace structural components and other harsh environments.

2024 T351 Manufacturing Standards and Specifications

2024-T351 aluminum alloy products generally comply with the following standards:

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheet, strip, and plate

- ASTM B210: Standard specification for aluminum and aluminum-alloy seamless pipe and tube

- ASTM B211: Standard specification for aluminum and aluminum-alloy bars, rods, and shapes

- AMS 4037: Aluminum and aluminum-alloy sheet, strip, and plate, 2024-T351

- AMS 4120: Aluminum and aluminum-alloy bars, rods, and shapes, 2024-T351

- AMS 4462: Aluminum and aluminum-alloy sheet, strip, and plate, 2024-T3

- QQ-A-250/5: Aluminum and aluminum-alloy sheet, strip, and plate

- QQ-A-250/4: Aluminum and aluminum-alloy sheet, strip, and plate

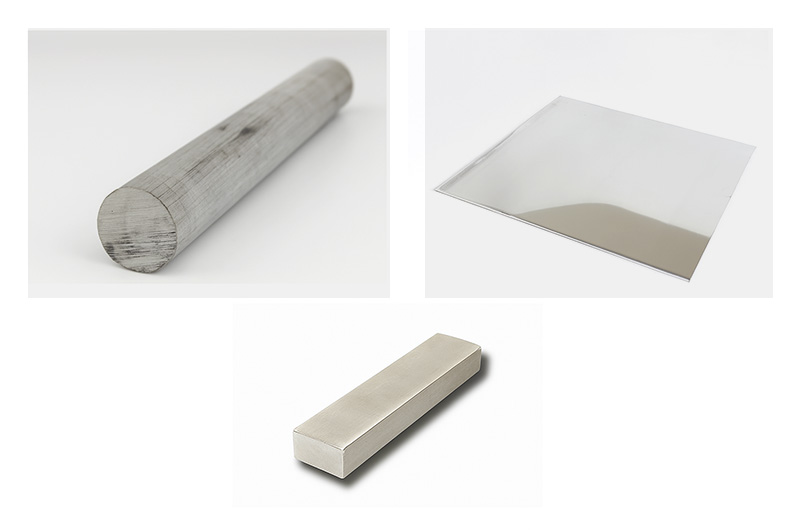

Haomei Aluminum 2024 T351 Supplied Forms

-

Aluminum Round Bar 2024-T351-Cold Finish

-

Aluminum Plate 2024-T351

-

2024 T351 Aluminum Flat Bar

Aluminum Round Bar 2024-T351-Cold Finish

Aluminum Round Bar 2024-T351-Cold Finish refers to 2024 aluminum alloy in T351 temper, produced as a solid round bar and finished through cold working. The cold working process further improves surface smoothness and dimensional accuracy.

- Applications: This product is commonly used for shaft components, high-strength connectors, fasteners, and other high-stress structural parts with a round cross-section in the aerospace industry.

- Features: High strength, excellent fatigue resistance, moderate machinability, good resistance to stress corrosion cracking, high surface finish, and excellent dimensional stability.

Aluminum Plate 2024-T351

This refers to the 2024 aluminum alloy in the T351 temper as a flat, thick, or solid plate. 2024 aluminum is known for its high strength and excellent fatigue resistance, making it ideal for aerospace and military applications. The T351 temper is achieved through solution heat treatment followed by stretching, which enhances its mechanical properties, such as improved yield strength and stress resistance.

- Applications: This product is commonly used in aerospace structures, aircraft skins, wing and fuselage components, and other high-stress structural parts.

- Properties: High strength, excellent fatigue resistance, moderate machinability, and good stress-corrosion cracking resistance.

2024 T351 Aluminum Flat Bar

2024 T351 Aluminum Flat Bar refers to 2024 aluminum alloy in T351 temper, produced as a solid flat bar.

- Applications: This product is commonly used for structural brackets, high-strength connectors, guide rail components, and other high-stress structural parts requiring a flat cross-section in the aerospace industry.

- Features: High strength, excellent fatigue resistance, moderate machinability, good resistance to stress corrosion cracking, strong adaptability of cross-sectional shape, and reliable dimensional stability.

Aluminum 2024 T351 Material Data Sheet

| Physical Properties | Metric | English | Comments |

| Density | 2.78 g/cc | 0.1 lb/in³ | AA; Typical |

| Mechanical Properties | |||

| Hardness, Brinell | 120 | 120 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 150 | 150 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 46.8 | 46.8 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 75 | 75 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 137 | 137 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 469 MPa | 68000 psi | AA; Typical |

| Tensile Yield Strength | 324 MPa | 47000 psi | AA; Typical |

| Elongation at Break | 19 % | 19 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Elongation at Break | 20 % | 20 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Modulus of Elasticity | 73.1 GPa | 10600 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Ultimate Bearing Strength | 814 MPa | 118000 psi | Edge distance/pin diameter = 2.0 |

| Bearing Yield Strength | 441 MPa | 64000 psi | Edge distance/pin diameter = 2.0 |

| Poisson's Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 138 MPa | 20000 psi | AA; 500,000,000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 26 MPa-m½ | 23.7 ksi-in½ | K(IC) in S-L Direction |

| Fracture Toughness | 32 MPa-m½ | 29.1 ksi-in½ | K(IC) in T-L Direction |

| Fracture Toughness | 37 MPa-m½ | 33.7 ksi-in½ | K(IC) in L-T Direction |

| Machinability | 70 % | 70 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 28 GPa | 4060 ksi | |

| Shear Strength | 283 MPa | 41000 psi | AA; Typical |

| Electrical Properties | |||

| Electrical Resistivity | 5.82e-006 ohm-cm | 5.82e-006 ohm-cm | AA; Typical at 68°F |

| Thermal Properties | |||

| CTE, linear 68°F | 23.2 µm/m-°C | 12.9 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 24.7 µm/m-°C | 13.7 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.875 J/g-°C | 0.209 BTU/lb-°F | |

| Thermal Conductivity | 121 W/m-K | 840 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 502 - 638 °C | 935 - 1180 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization. |

| Solidus | 502 °C | 935 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

| Processing Properties | |||

| Annealing Temperature | 413 °C | 775 °F | |

| Solution Temperature | 256 °C | 493 °F | |

2024 T351 Applications

2024 T351 Aerospace Applications

2024 T351 is widely used in the aerospace field, especially in aircraft structures such as wings and fuselage, as well as other high-strength applications such as gears, shafts, and fasteners.

Aircraft Structural Components:

- Wing skin and structural framework

- Fuselage frames and bulkheads

- Tail and control surface structures

- Floor beams and floor support structures

Aircraft Interiors:

- Seat frames and structural components

- Overhead luggage compartment structures

- Interior decorative panel support structures

Other Applications of 2024 T351

Automotive and Transportation

- Racing/high-performance vehicles

- Commercial vehicles

- Rail transportation

- Marine vessels

Industrial and Machinery

- Mold manufacturing

- Precision machinery

- Hydraulic systems

- Power transmission

Construction and Infrastructure

- Building structures

- Decorative applications

- Infrastructure projects

- Marine environments

Other Specialized Fields

- Medical equipment

- Optics/photography

- Watches/precision instruments

- Energy industry

2024 T351 Advantages and Disadvantages

2024 T351 Advantages

- High strength-to-weight ratio; one of the strongest aluminum alloys

- Excellent fatigue performance and fracture toughness

- Superior machinability

- Maintains strength well at temperatures above 125°C

- Mature manufacturing processes and supply chain

2024 T351 Disadvantages

- Poor corrosion resistance; requires special protective treatments

- Poor weldability; usually requires riveting or mechanical fastening

- Significant anisotropy; performance varies with direction

- Sensitive to stress concentration

- Relatively high cost

2024 T351 Comparative Analysis with Similar Products

Comparison of 2024 T351 with Other 2024 Series Tempers

The 2024 series aluminum alloys include multiple tempers, among which T3 and T4 are most relevant to T351. The main difference between T351 and T3 is that T351 is suitable for thick plates and stress-relieved, stretched products, eliminating internal stresses and improving dimensional stability, making it especially suitable for large structural components that require machining.

| Performance Index | 2024-T3 | 2024-T351 | 2024-T4 |

| Tensile Strength (MPa) | 400-430 | 470 | 400-430 |

| Yield Strength (MPa) | 270-280 | 325 | 270-280 |

| Elongation (%) | 10-15 | 10-15 | 10-15 |

| Typical Applications | Thin plates, structural components | Thick plates, large structural components | General structural components |

Comparison of 2024 T351 and 7075-T6 Aluminum Alloy

7075-T6 is another high-strength aluminum alloy, often compared with 2024-T351.

| Performance Index | 2024-T351 | 7075-T6 |

| Tensile Strength (MPa) | 470 | 500-570 |

| Yield Strength (MPa) | 325 | 480-505 |

| Elongation (%) | 10-15 | 5-11 |

| Hardness (HB) | 120-145 | 150 |

| Density (g/cm³) | 2.78 | 2.80 |

| Corrosion Resistance | Poor, requires protective treatment | Moderate, requires protective treatment |

| Cost | Moderate | High |

Advantages:

- 2024-T351 has better fatigue performance and fracture toughness

- 2024-T351 maintains strength better than 7075 at temperatures above 125°C

- 2024-T351 has slightly better machinability than 7075

- 2024-T351 is lower in cost compared to 7075

Disadvantages:

- 7075 has higher room-temperature strength, especially yield strength

- 7075 exhibits better stress-corrosion cracking resistance

- 7075 has superior hardenability compared to 2024-T351

- 7075 performs slightly better than 2024 at low temperatures

- Comparison of 2024 T351 with 6061-T6 Aluminum Alloy

Comparison with 6061-T6 Aluminum Alloy

6061-T6 is a medium-strength aluminum alloy, widely used for general structural purposes.

| Performance Index | 2024-T351 | 6061-T6 |

| Tensile Strength (MPa) | 470 | 290-310 |

| Yield Strength (MPa) | 325 | 276 |

| Elongation (%) | 10-15 | 10-12 |

| Hardness (HB) | 120-145 | 95 |

| Density (g/cm³) | 2.78 | 2.70 |

| Corrosion Resistance | Poor, requires protective treatment | Good, no special treatment required |

| Weldability | Poor, prone to cracking | Good, suitable for various welding methods |

| Cost | High | Low |

Advantages:

- 2024-T351 has significantly higher strength than 6061-T6, with tensile strength approximately 60% higher

- 2024-T351 exhibits superior fatigue strength and fracture toughness compared to 6061

- 2024-T351 maintains better performance at high temperatures

Disadvantages:

- 6061-T6 has significantly better corrosion resistance than 2024-T351

- 6061-T6 has excellent weldability, while 2024-T351 is difficult to weld

- 6061-T6 has lower manufacturing costs and is easier to form and machine

- 6061-T6 has lower anisotropy, providing more uniform performance

Comparison of 2024-T351 and 2124-T851 Aluminum Alloy

| Performance Index | 2024-T351 | 2124-T851 |

| Tensile Strength (MPa) | 470 | 485-515 |

| Yield Strength (MPa) | 325 | 420-450 |

| Elongation (%) | 10-15 | 8-12 |

| Exfoliation Corrosion Resistance | Poor | Good |

| Stress Corrosion Cracking Resistance | Poor | Good |

| Cost | Moderate | High |

Advantages:

- 2024-T351 has better toughness and fracture toughness than 2124-T851

- 2024-T351 has better machinability, especially in cold working

- 2024-T351 is lower in cost compared to 2124-T851

Disadvantages:

- 2124-T851 has higher strength, especially yield strength

- 2124-T851 has significantly better corrosion resistance than 2024-T351

- 2124-T851 has superior exfoliation corrosion and stress corrosion cracking resistance

- 2124-T851 has better stability at high temperatures

2024-T351 Selection Guide

Optimal Applications for 2024-T351

- Structural applications requiring high strength and lightweight

- Components subjected to cyclic or dynamic loads

- Working parts in moderate temperature environments (<150°C)

- Precision components requiring high machining accuracy

- Aerospace structural components and critical parts

Alternative Options to 2024-T351

- For higher strength: consider 7075-T6 or 2124-T851

- For better corrosion resistance: consider 6061-T6 or 5052

- For better weldability: consider 6061-T6 or 5083

- For lower cost: consider 6061-T6 or 6063